Automate 2024 Booth Preview

It’s that time of year again for Automate! This year, the Dorner team is excited to join our new Conveyance

It’s that time of year again for Automate! This year, the Dorner team is excited to join our new Conveyance

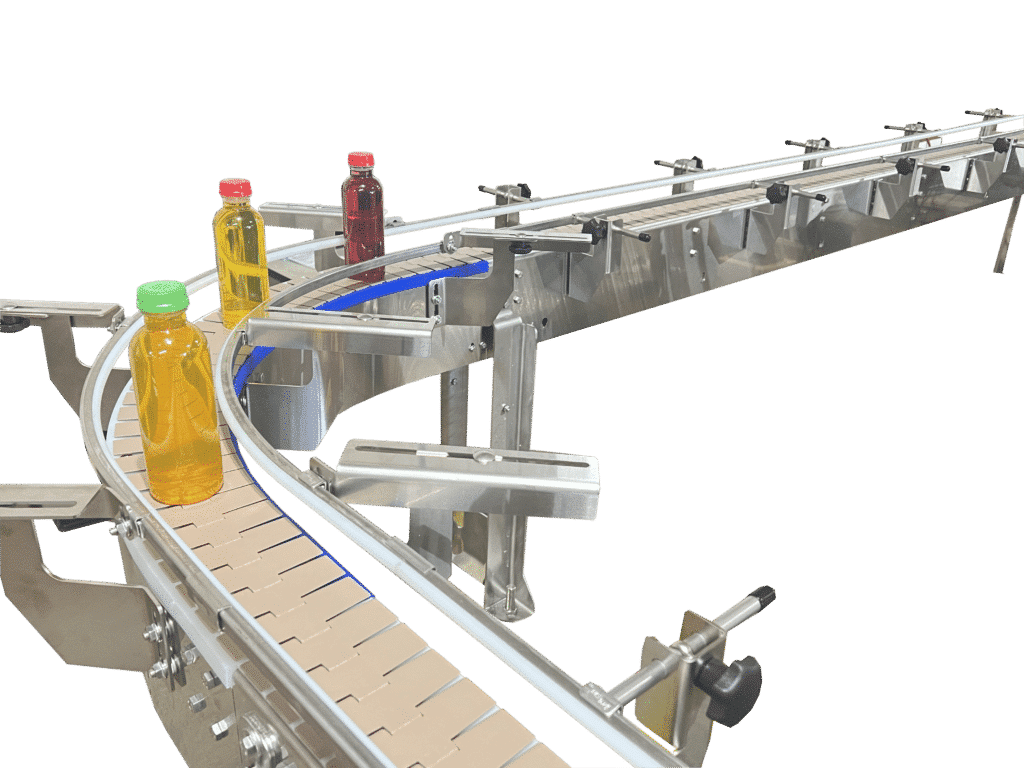

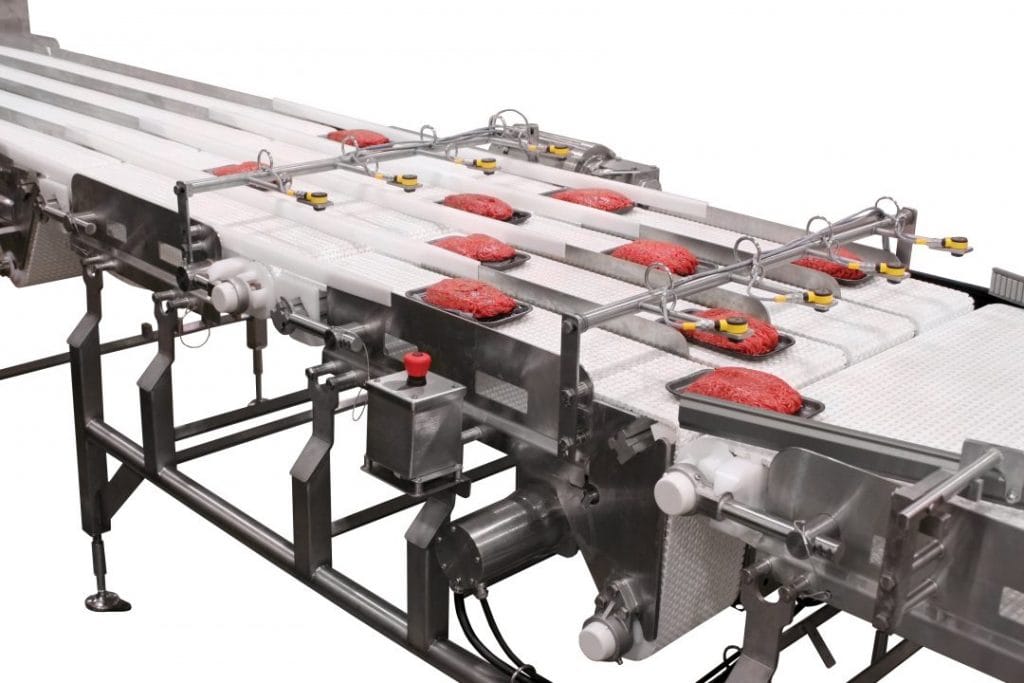

The AquaGard GT offers a truly unique conveyance solution for packaged food and beverage applications. Utilizing a flexible chain belt

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

In the bustling world of pet food manufacturing, efficiency, safety, and precision are paramount. From ingredient processing to inspection and

Pack Expo East is just around the corner, and Dorner will again be sharing a booth with Garvey to showcase

When it comes to conveyor technology, it’s safe to call both Garvey and Dorner industry leading experts. In 1967 Fran

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

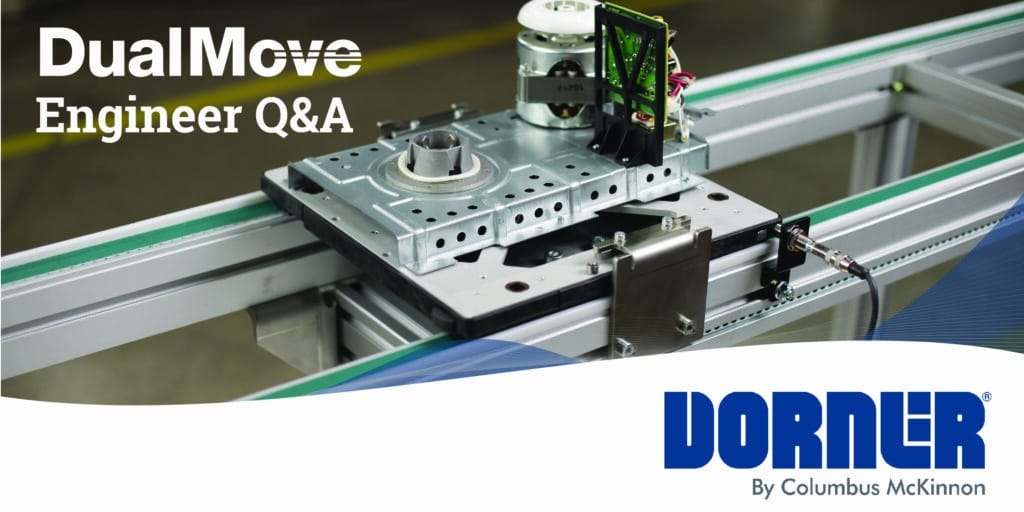

Discussion with Dan E., Anete F., & Marco P. As the latest addition to Dorner’s line of pallet system conveyors,

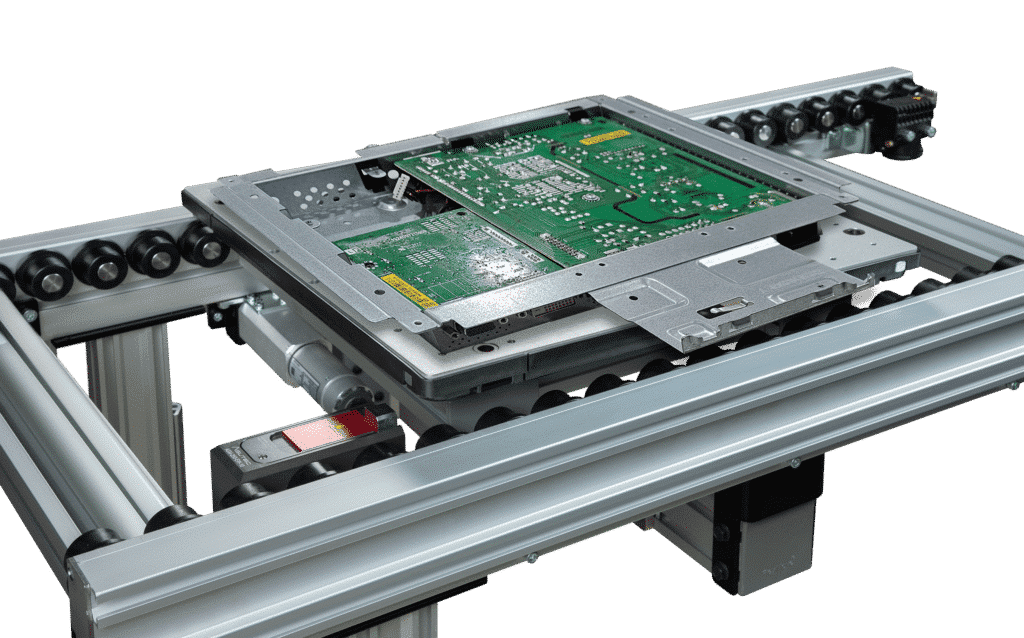

In the highly competitive realm of computer monitor manufacturing, Dorner’s state-of-the-art conveyor systems prove instrumental in optimizing production processes, adding

Dorner’s ability to create the perfect solution for almost any application has been the defining factor that positioned us as

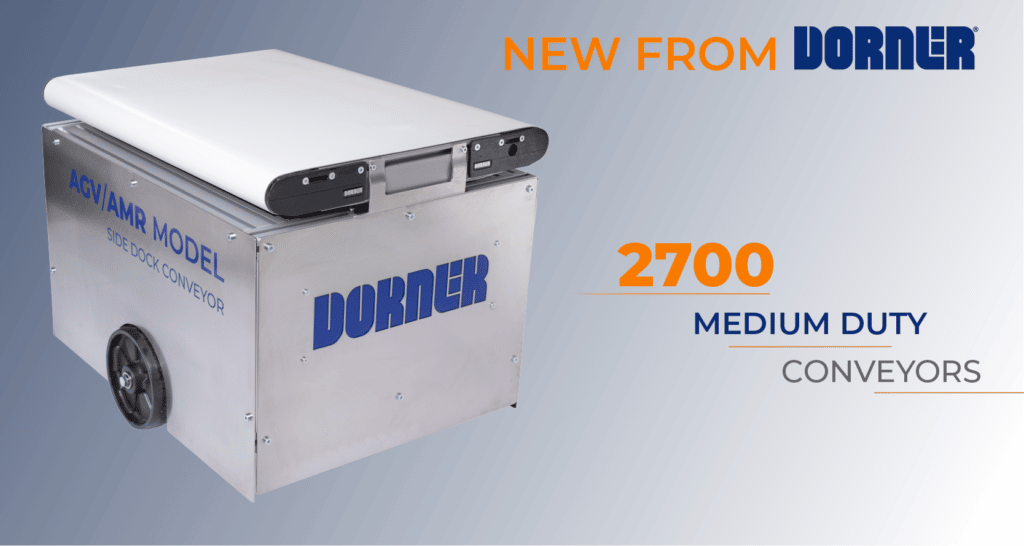

The 2700 Medium Duty conveyor is the latest addition to Dorner’s low-profile precision conveyor family, and we are excited to

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

The DualMove is Dorner’s newest addition to the Pallet System line of conveyors and has replaced the 2200 Precision Move

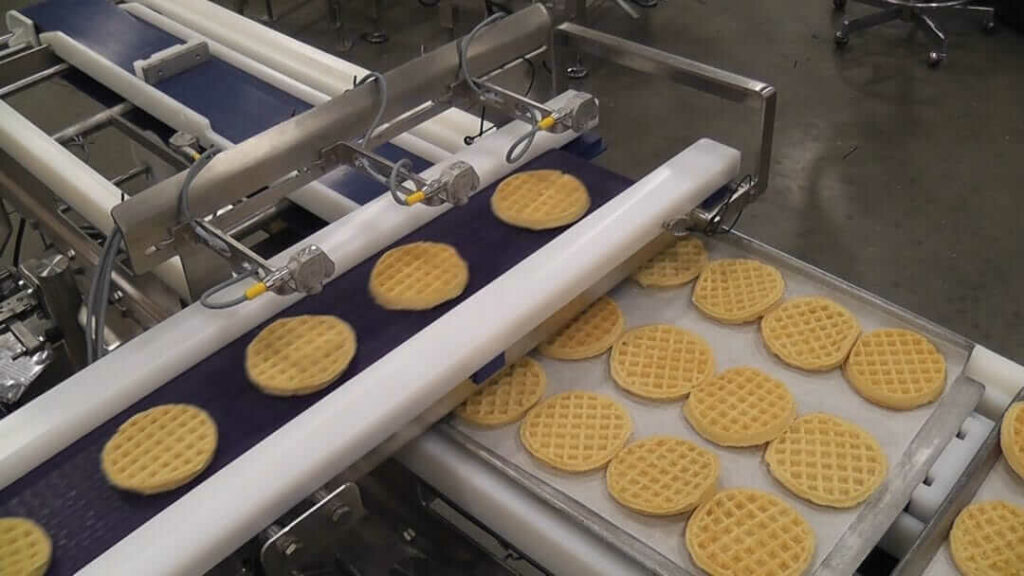

Effective product transfers ensure quality, efficiency, and safety in any production line. Whether a product needs to be transferred from

In the ever-evolving food processing and packaging landscape, automation has become more than just a buzzword; it’s a transformative force

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

In modern manufacturing facilities, space is premium, and every piece of equipment must work in sync with other machinery and

As the demand for packaged food continues to rise, manufacturers are constantly challenged to find new innovative solutions to streamline

In the fast-paced world of food processing, efficiency and precision are crucial elements to ensure the delivery of safe, high-quality

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

Food-based applications often call for multiple conveyors throughout food processing and packaging lines. Conveyors must frequently interface with other machinery

The potential of foodborne illness is a constant concern for producers and distributors, who prioritize consumer safety above all else.

Conveyors are often one of the most overlooked components within a more extensive snack food, bakery processing, or packaging line.

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

Prioritizing product quality is essential for companies to ensure consumer safety, meet government regulations, avoid costly recalls, and build trust.

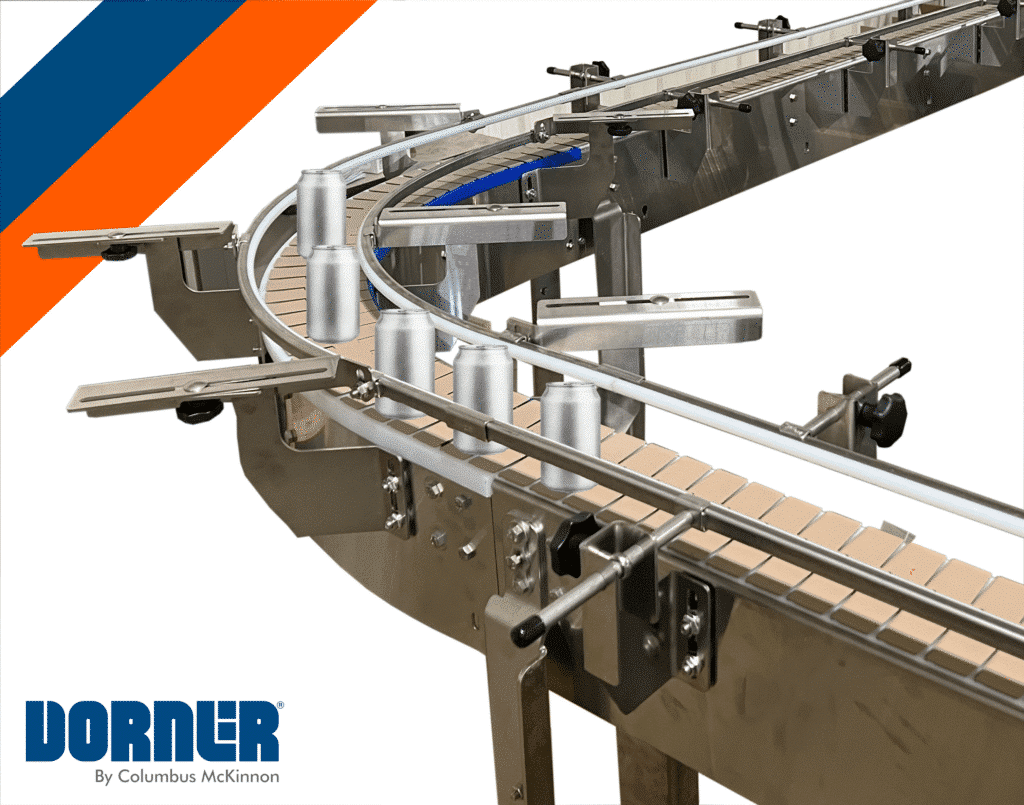

Craft breweries have taken the beer industry by storm in recent years, offering a diverse array of unique and flavorful

The conveyor industry has been a cornerstone of modern manufacturing and material handling for decades, revolutionizing production lines and streamlining

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

One more week until the highly anticipated Pack Expo 2023! Automated material handling is taking over the packaging and manufacturing

Pack Expo 2023 is just around the corner, it will be exciting to see all of the new packaging technology

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy