- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Consumer Packaged Goods (CPG) Manufacturing Conveyors

Elevate efficiency, minimize downtime, and ensure product quality with Dorner’s reliable conveyor solutions, specifically designed for the unique demands of Consumer Packaged Goods (CPG) manufacturing.

Previous

Next

CPG Manufacturing Solutions from Dorner

At Dorner, we understand the complexities of CPG manufacturing. From precise handling of delicate electronics to ensuring hygiene in food and beverage applications, our diverse range of conveyor systems caters to your specific needs.

We go beyond just providing equipment; we become your strategic partner, offering solutions that enhance your operations and empower you to navigate the intricacies of CPG manufacturing with confidence.

Benefits of Dorner's CPG Manufacturing Conveyor Belts & Systems

Optimizing material flow is key to streamlining operations and boosting profitability in CPG manufacturing. Dorner conveyor solutions deliver tangible advantages designed to address your specific needs:

Precision and Accuracy ✓

Precise movement and accurate positioning ensure seamless production processes, minimizing errors and waste while optimizing throughput.

Hygiene Compliance ✓

Easy-to-clean surfaces and sanitary designs meet strict hygiene requirements, safeguarding product integrity and safety in food, beverage, and pharmaceutical applications.

Reliability and Durability ✓

Built to withstand demanding environments, Dorner conveyors offer uninterrupted operation, minimizing downtime and maximizing production efficiency.

Choose Dorner and experience the difference efficient, reliable, and adaptable conveyors can make in your CPG manufacturing.

Flexibility and Adaptability ✓

Modular and configurable systems adapt to changing production lines and seasonal demands, ensuring efficient material handling for diverse CPG products.

Key Applications of Dorner Conveyors in CPG Manufacturing

Optimize your CPG warehouse operations for efficiency and productivity with Dorner’s diverse range of conveyor solutions. From effortless product movement to enhanced storage and retrieval, our systems are designed to address the unique challenges of your industry by offering the following:

Effortless Product Movement

Dorner’s conveyor systems ensure smooth, precise movement of diverse CPG products. Low-profile designs like the DCMove conveyor maximize space utilization while handling even heavy loads, ideal for efficient distribution center operations.

Transportation conveyors efficiently move palletized goods, individual packages, or bulk containers across your warehouse, minimizing handling time and ensuring on-time delivery.

Enhanced Storage & Retrieval

Maintain controlled product queues for optimized production flow with Dorner’s accumulation conveyor systems. These systems ensure proper spacing, facilitating efficient sorting and fulfillment.

Integrate Dorner conveyors with your Automated Storage & Retrieval Systems (AS/RS) for seamless product access, storage optimization, and error-free retrieval. Additionally, AMR conveyors automate storage and retrieval processes, reducing manual labor, space requirements, and the risk of product damage.

Integrated Processing & Packaging

Combine manual and automated processes seamlessly for increased production speed and reduced labor costs with Dorner’s printing and packaging conveyor systems. These systems are ideal for precise product placement applications commonly found in CPG manufacturing.

Customize conveyor systems specifically for your CPG needs, from palletizing and depalletizing to sorting and assembly line operations, with Dorner’s product handling conveyors.

Labeling

We recognize the critical role of precise and efficient labeling in the consumer packaged goods (CPG) manufacturing industry. To address this need, we offer a comprehensive suite of precision conveyor solutions designed to meet specific requirements of labeling applications.

These solutions include high-speed conveyors that accurately position product and seamlessly integrate with labeling machinery to facilitate quick and accurate label application on a variety of CPG products.

Quality Assurance

Integrate conveyors into your quality control processes with Dorner’s inspection conveyor systems. These systems enable smooth product movement for thorough inspection and rapid corrective action, ensuring the highest quality standards for your CPG products.

Dorner’s Industrial Conveyor Systems for Consumer Packaged Goods

DualMove

This innovative system utilizes dual timing belts to seamlessly handle palletized goods, ensuring efficient packaging and inspection of various CPG products optimizing warehouse and production floor layouts.

AquaGard Series

Crafted with food-grade stainless steel and featuring easy-to-clean surfaces, these conveyors prioritize hygiene. Ideal for packaged food, beverage, and pharmaceutical applications, the hygenic and durable construction of the AquaGard series ensures compliance with strict sanitation standards and safeguards product safety.

Our newest sanitary conveyor, the AquaGard GT offers seamless integration with processing and packaging machinery, adding speed to your production line while maintaining the highest possible product quality.

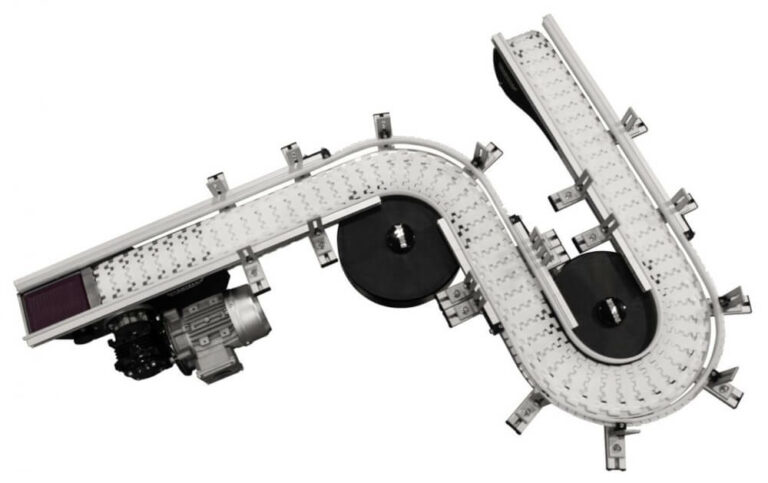

FlexMove Conveyors

These modular conveyors boast exceptional flexibility, allowing for straight runs, curves, inclines, and declines in various configurations, adapting seamlessly to changing production lines and seasonal demands, ideal for CPG manufacturers with diverse product ranges.

3200 Series

Built for heavy-duty applications, these robust conveyors handle high product volumes and heavier loads with ease. Perfect for high-volume production lines in industries like warehousing & packaged goods, ensuring uninterrupted operation and durability.

2200 Series

Designed for precise movement and positioning, these conveyors feature a low-profile design and various belt options, ideal for handling delicate or intricate products, such as electronics or pharmaceuticals, where precise handling is paramount to maintain product quality.

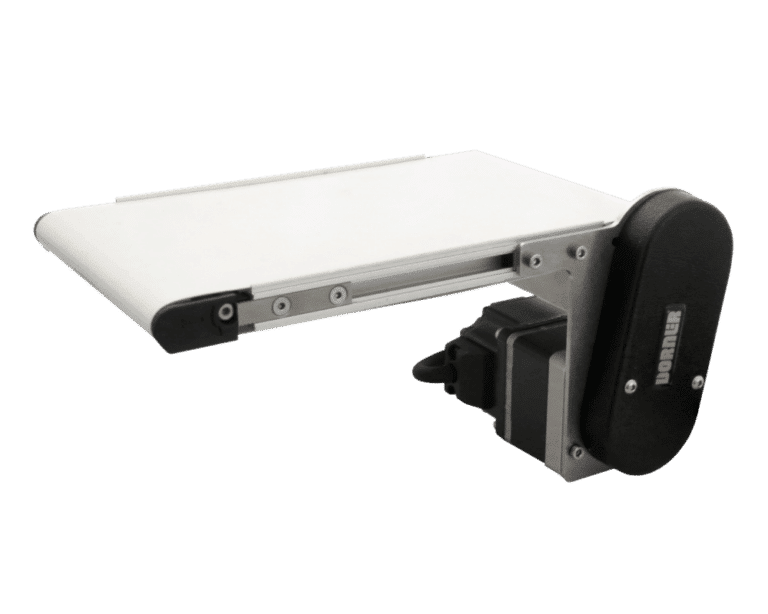

1100 Series

Featuring a durable, low profile design, these versatile conveyors are ideal for light load applications. The compact construction of the 1100 series offers the ideal solution for small parts handling and integrating inside machinery for seamless product transport through every step in production.

How Dorner Is Streamlining CPG Operations

At Dorner, we understand the unique challenges faced by Consumer Packaged Goods (CPG) manufacturers in optimizing production and maintaining efficiency. Our conveyor automation solutions are specifically designed to address these challenges, transforming your operations and propelling your business forward.

Unleash Operational Excellence

Dorner offers a comprehensive range of industrial-grade conveyor systems designed to seamlessly integrate into your CPG manufacturing processes. From precise handling of delicate electronics to efficient bulk transport of heavy goods, our systems cater to the diverse needs of the CPG industry.

Embrace Lean Manufacturing Principles

Our conveyors empower you to implement lean manufacturing principles within your facilities. By automating material handling, you can eliminate non-value-added activities, reduce waste, and optimize production throughput. This translates to increased efficiency, reduced labor costs, and enhanced profitability.

Dorner – Your Trusted Partner in CPG Success

Dorner goes beyond just providing custom conveyors. We offer a comprehensive partnership, including:

- Expert engineering and consultation

- Seamless installation services

- Comprehensive training and maintenance programs

Contact Dorner today to discuss your specific CPG manufacturing needs and discover how our conveyor automation solutions can propel your business toward greater efficiency and success.

Customizable Solutions for Every Stage

Dorner doesn’t believe in one-size-fits-all solutions. Our customizable conveyor systems can be tailored to fit any specific workflow or space constraints. Whether you require inspection and testing stations, product elevation, or merging, our team of expert engineers can design a solution that perfectly aligns with your unique needs.

Streamlining CPG Production with Dorner's Comprehensive Services

Beyond industry-leading conveyor systems, Dorner offers a comprehensive suite of services designed to maximize your CPG manufacturing efficiency and uptime.

Installation Services

Dorner’s expert service team provides professional, on-site installation for your custom or standard Dorner conveyors. From delivery and staging to setup and training, our engineers prioritize efficiency and safety, ensuring your equipment is ready for optimal performance. Whether you choose internal or third-party installation, a dedicated Dorner service manager is available to ensure smooth execution.

Training Services

Dorner goes beyond simply providing equipment. Our team offers comprehensive training to empower your workforce through group and individual training, safety, troubleshooting, and maintenance, and extensive resources that provide your team with ongoing support through access to online guides, videos, and readily available support personnel.

Unparalleled Aftermarket Support

Dorner remains your trusted partner throughout your conveyor system’s lifecycle, with 24/7 parts availability to ensure prompt access to replacement parts when needed. A Dorner service professional can also visit your site to create a customized spare parts list and identify potential maintenance needs, minimizing disruptions.

We also offer a preventative maintenance program tailored to your specific needs. This program includes a free initial site evaluation and customized proposal. A few of the services included in the conveyor maintenance program include:

- Inspecting

- Adjusting belt tracking and tension

- Debris removal

- Lubrication

The Level 2 package offers a 10 percent discount on all parts ordered as part of the program, as well.

By investing in Dorner’s comprehensive services, you gain more than just high-quality conveyor systems. You gain a dedicated partner committed to optimizing your CPG manufacturing operations for long-term success.

Frequently Asked Questions About Dorner’s CPG Manufacturing Solutions

What Industries Benefit Most from CPG Conveyor Solutions?

Dorner’s conveyors cater to a wide range of Consumer Packaged Goods (CPG) businesses, including food & beverage, health & beauty, household goods, toy manufacturers, clothing and apparel companies, and more.

How Do Dorner’s Conveyors for CPG Manufacturing Work?

Dorner’s CPG conveyors utilize motors, belts, and support structures for product movement. Options like rollers, sensors, and controls offer precise control and diverse functionalities. From gravity-powered options to heavy-duty chains, Dorner’s conveyors adapt to your specific CPG manufacturing needs.

Which Dorner Conveyor Is Best for CPG Manufacturing?

Selecting the perfect Dorner conveyor for your CPG production line requires considering:

- Product size

- Weight

- Fragility

- Production volume

- Sorting needs

- Available space

Collaborate with Dorner’s experts to identify the ideal solution, ensuring optimal efficiency, safety, and production success within your unique CPG manufacturing environment.

Consumer Packaged Goods (CPG) Conveyors from Dorner: Custom-Engineered for Diverse Product Handling & Peak Efficiency

Contact Dorner today to explore how our CPG-focused conveyor systems can optimize your production flow, enhance safety, and ultimately, maximize your profitability.

Dorner - Global Headquarters

975 Cottonwood Ave

Hartland, WI 53029, USA

(800) 397-8664 | (262) 367-7600

info@dorner.com

Products

Menu

Industries

Menu

Quick Links

Menu

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy