Meat & Poultry

Previous

Next

Benefits of Dorner’s Meat & Poultry Conveyors

- Dorner Ultimate line of conveyors are designed to meet USDA regulations for red meat & poultry

- By eliminating horizontal surfaces, blind spots and harbor points, food and water won’t accumulate, preventing the growth of bacteria.

- Easy access to all areas of the conveyor for cleaning allows you to keep lines running and the conveyor at the highest level of sanitation.

- Eliminating the chances of bacteria and contamination creates a safer conveyor and prevents the spread of illness to your customers.

Dorner has experience with products such as:

- Sausage Links & Patties

- Hot Dogs & Corn Dogs

- Cold Meat Chubs

- Pepperoni Logs

- Sausage Trays

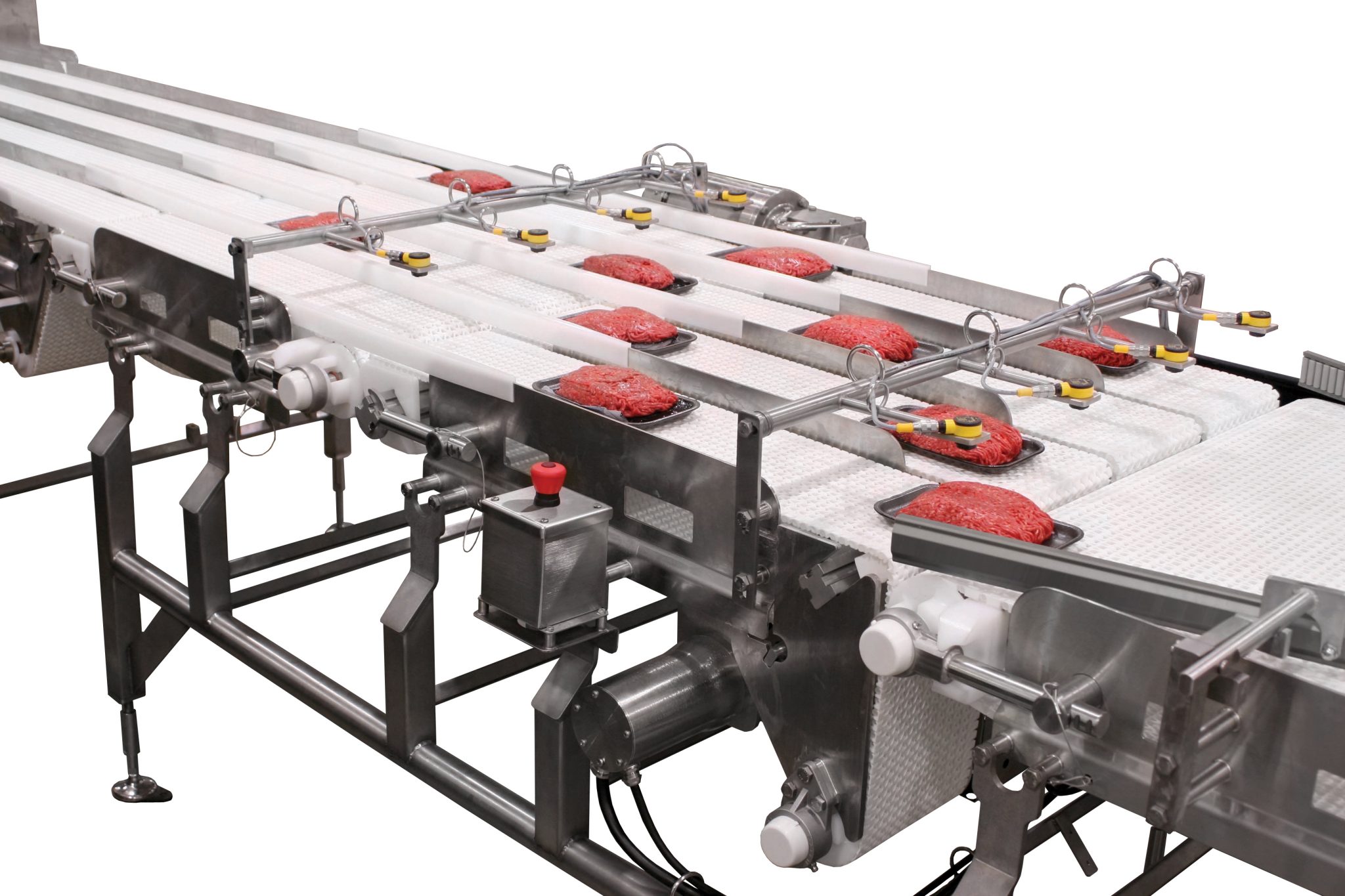

- Ground Beef

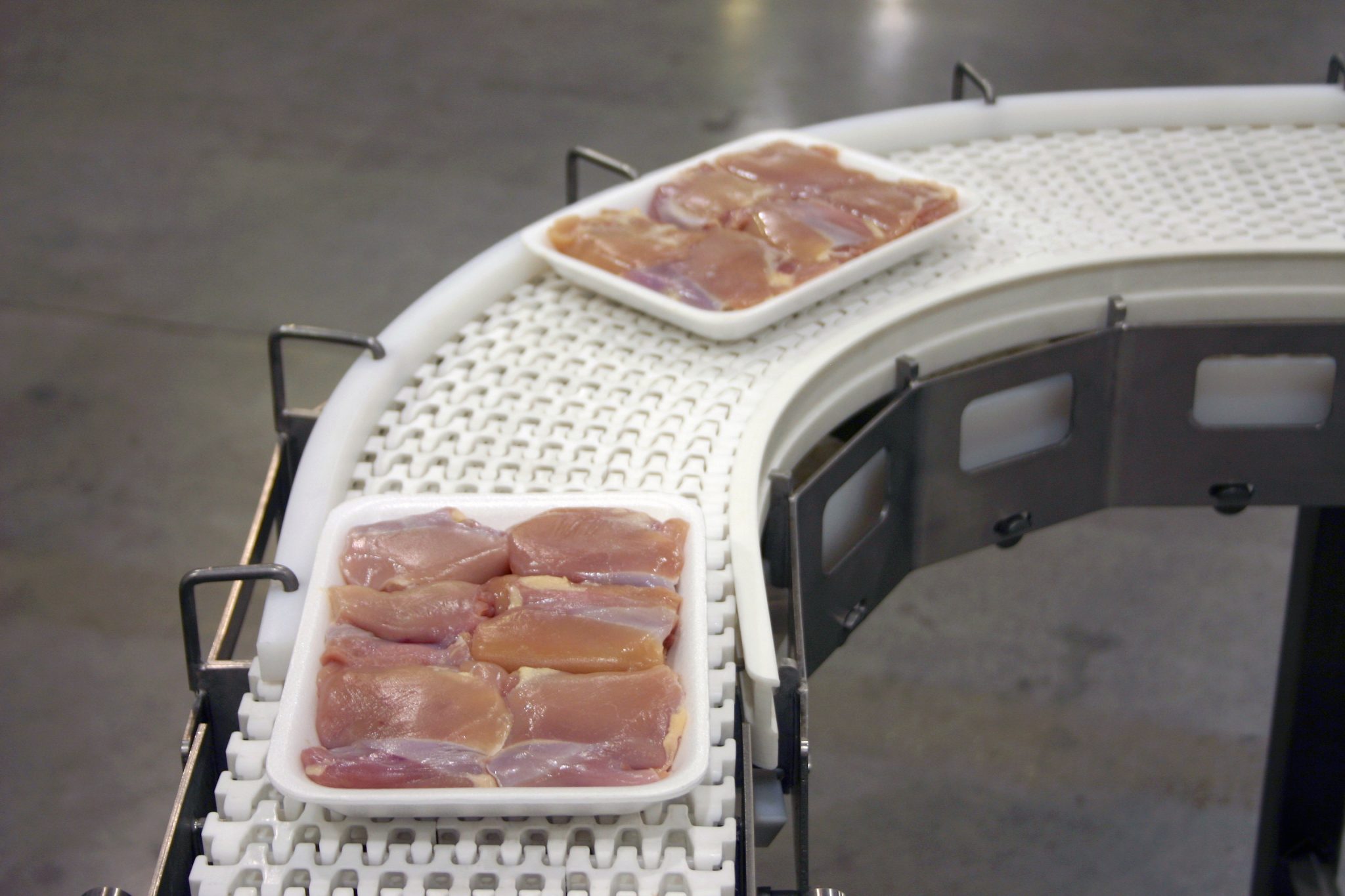

- Marinated Chicken Breasts

- Ham Steaks

- Chicken Nuggets

AquaPruf® Series Conveyor

Using an AquaPruf series conveyor from Dorner is a great way to move product along while maintaining sanitary requirements. The AquaPruf series is designed with food sanitation requirements in mind. These design features include:

- Tip-up, tool-less pulleys and belt lifters for easy access for cleaning

- Rounded cross members to eliminate horizontal edges

- Solid UHMW wear strips for quick drainage and easy cleaning

- V-guided belt tracking

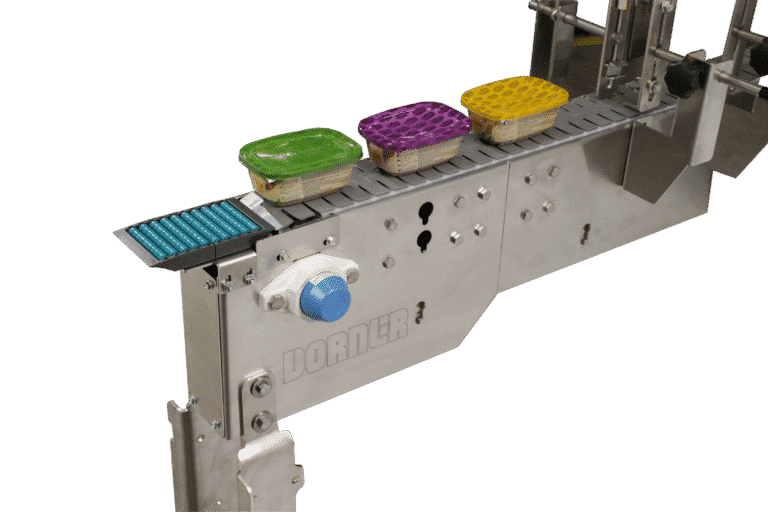

AquaGard® Series Conveyors

The AquaGard line of conveyors is designed for a wide variety of packaged food applications in sanitary environments that require conveyor wipe-downs. Features include:

- Solid UHMW wear strips located in welded cross members for durable belt support

- Frame constructed of TIG welded 304 stainless steel

- Open design with minimal horizontal surfaces

- Low-profile frame and flexible belt options

Engineered Solutions

At Dorner we recognize that our standard conveyor solutions aren’t always right for everyone. Our Engineered Solutions Group specializes in designing and implementing custom solutions for our customers. Our team of engineers will work with you to make sure that you get a quality conveyor system that fits your specific needs. In the food industry especially where each application differs greatly we are able to custom design a solution to fit your unique needs.

If you need to add a standard straight run to your line or need something more custom, Dorner will make sure your needs are met. Our Sanitary lines are designed for quick and easy cleaning in mind so your production lines are down for less time and production levels are up.

Conveyors Meat & Poultry

AquaPruf Conveyors

- Tool-less disassembly. Cleaning prep in under a minute, complete disassembly in less than 3 minutes

- Optional frame cut-outs and belt lifters for continuous access to inside of the conveyor

- Tip-up tails allow for quick release of belt tension

- Continuous TIG-welded 304 stainless steel frame

- Spiral cam belt tensioning with patent pending thread-less design

- Patented sprocket alignment key

- Gearless, oil-free iDrive2 sanitary motorized roller

AquaPruf Ultimate Conveyors

Dorner’s AquaPruf Ultimate conveyors are 3-A Certified. These product upgrades ensures that the AquaPruf Ultimate meets the strict requirements of 3-A and is optimally designed for use in food applications such as meat, poultry, fish and ready-to-eat.

AquaGard GT Conveyors

- Best for: packaging, bottling, dry food processing, part handling, long lengths, accumulation and buffering

- Smooth frame design for ease of cleaning

- Capable of multiple curves as well as inclines and declines on a single conveyor

- Bolt together construction for modularity and future add-ons

- Innovative transfer options

- Powered transfers

- Standard tails side to side transfer

- Side transfer modules

AquaGard 7350 Conveyors

- Rugged and Durable Design

- 304 Stainless Steel frame features open design with minimal horizontal surfaces

- Designed for wipe down and low pressure wash-down with non-caustic chemicals

- V-guided belt tracking on belted models

- Tip-up tails for access inside the conveyor for cleaning and maintenance

- Safest chain in the industry with chain openings less than 4 mm even on curves

- Unique chain design virtually eliminates friction providing capacity for up to 4 curves on a single conveyor

Dorner — Asia

Dorner (M) SDN. BHD.

128 Jalan Permatang Damar Laut, Bayan Lepas 11960

Penang, Malaysia

Products

Menu

Industries

Menu

Quick Links

Menu

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy