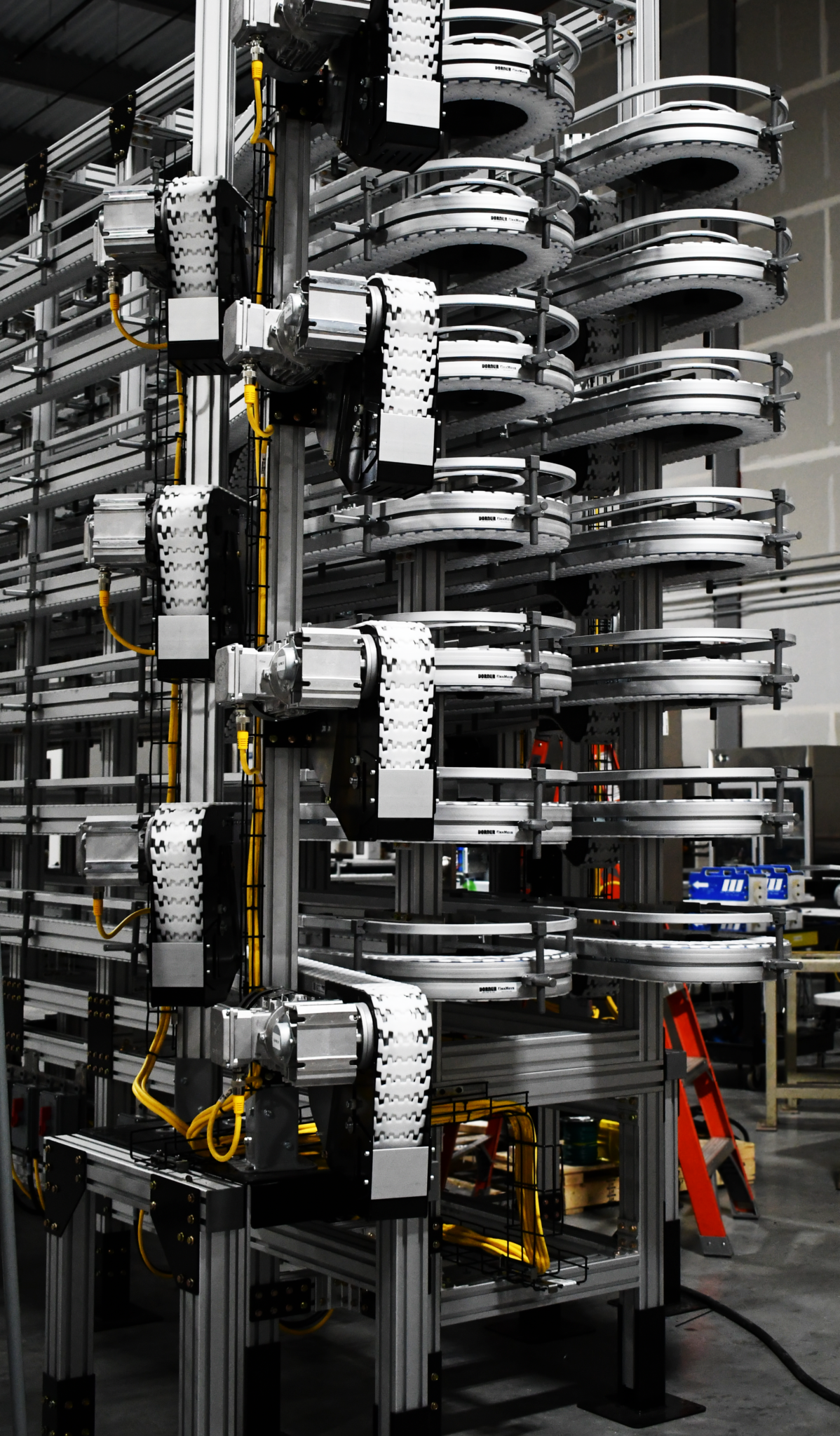

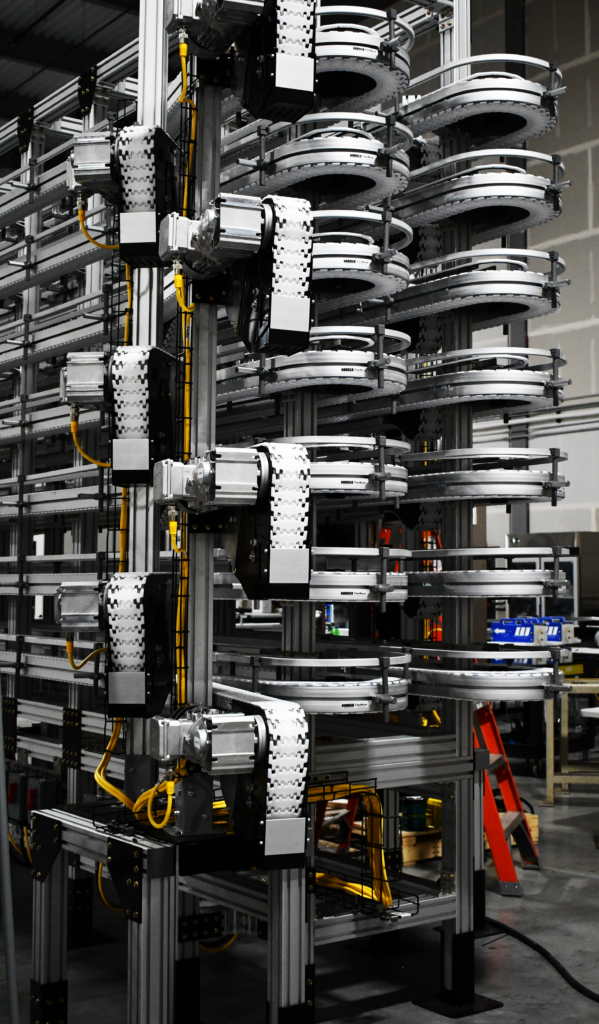

FlexMove Alpine Conveyors

The Alpine Conveyor is a compact spiral configuration commonly used as an accumulation or elevating buffer zone between machines or as a process step for cooling or drying. It can also be used for line balancing or product changeover purposes.

Alpines can be configured as an elevating/ lowering system with a single or double serpentine configuration. Uses include an in-line accumulator with entry and exit at different levels, or an in-line or off-line accumulator with entry and exit at the same level.

Benefits of FlexMove Alpine Conveyor:

- Keeps a constant sequence while buffering or accumulating products

- Uses a gentle slope while changing elevations and preventing product damage

- Maximizes vertical space, ensures the efficient utilization of machines with different speeds, and provides storage for pucks in FlexMove pallet system applications

- The accumulation zone is simple yet efficient and provides the possibility to continuously have bottleneck machines running

- Reduces the effects of machinery failures. It will accumulate the products from one machine while the nest machine in the line is being repaired or adjusted

- Option of adding more levels when additional capacity is needed

View the complete Specification Sheet here: FlexMove Alpine Conveyor Spec Sheet

Specifications:

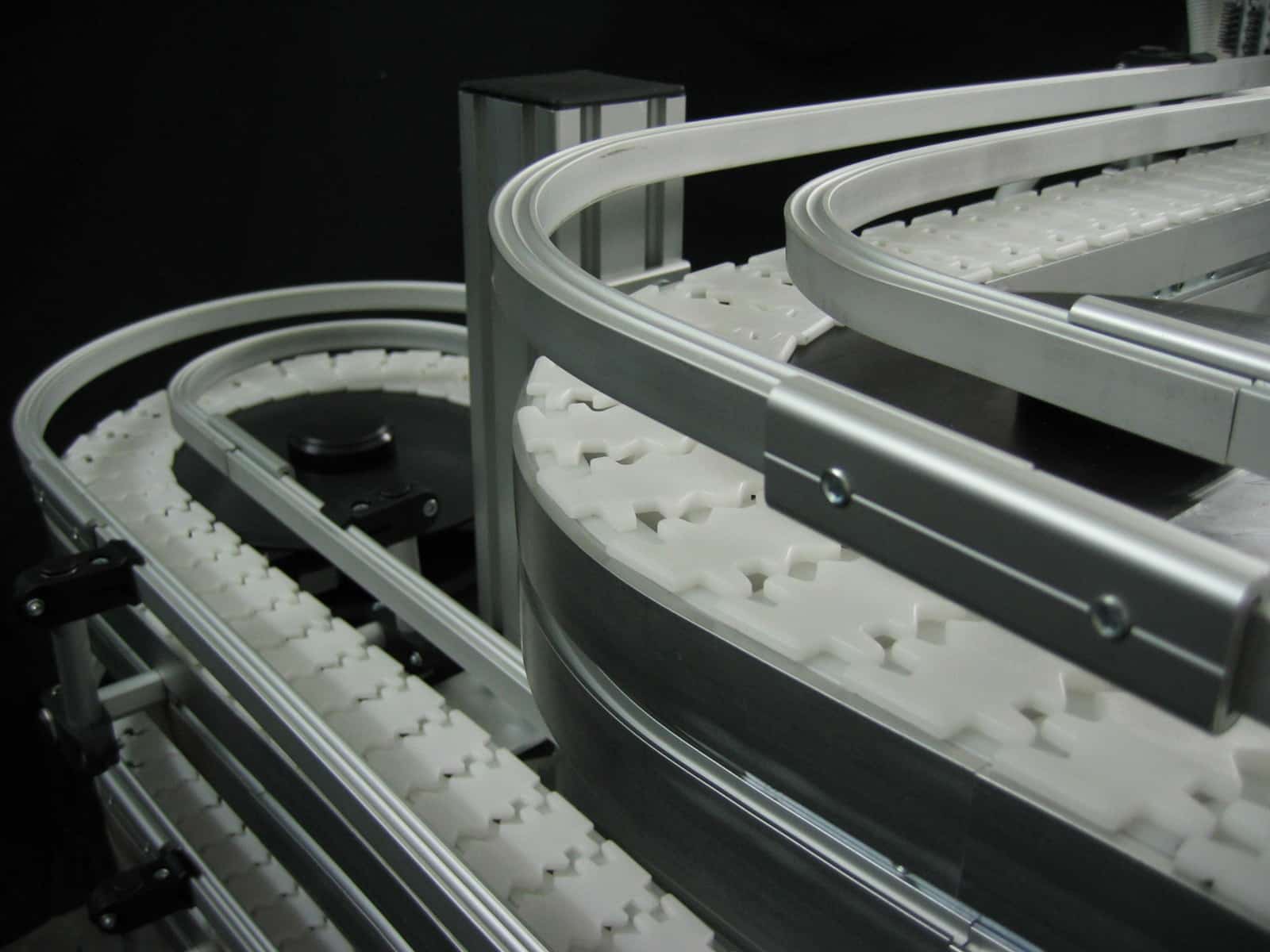

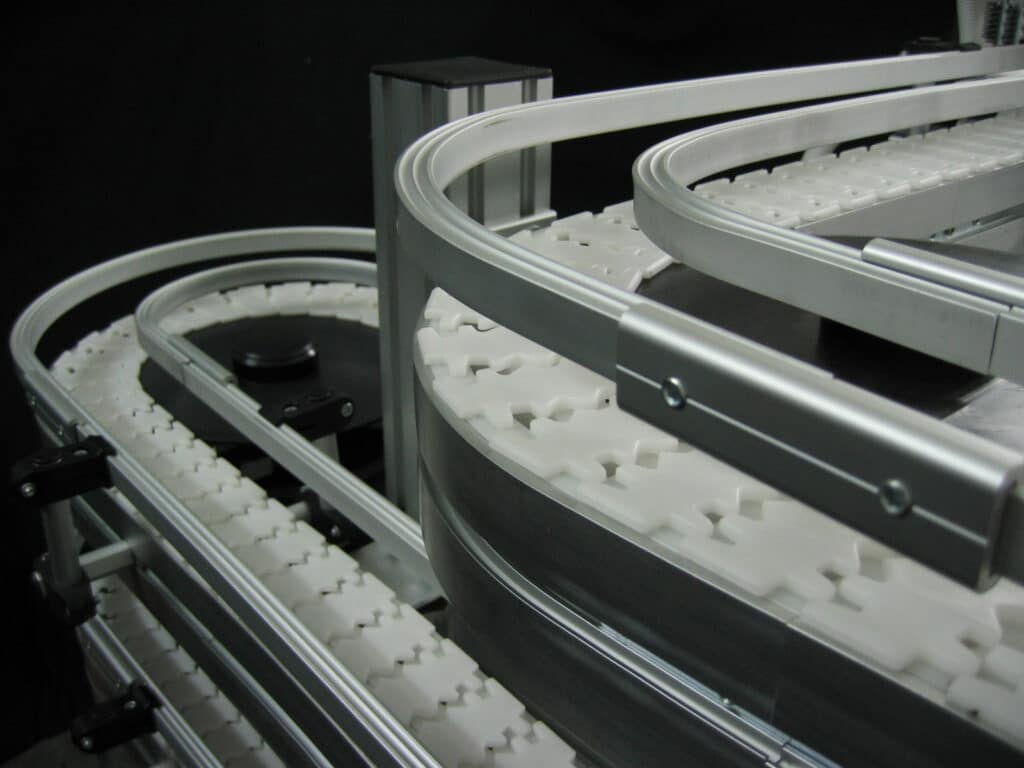

- Products can be round, square, oval or rectangular

- Chain Widths: 65, 85, 105, 150 mm

- Chain Lengths:

- Return Chain up to 23 m (75 ft)

- Top Running Chain up to 76 m (250 ft)

- Basic Configurations:

- One Direction, Return Chain: entry and exit at different levels, up to 23 m (75 ft) total length

- One Direction, Top Running Chain: entry and exit at different levels, up to 30 m (100 ft) total length

- Dual Direction, Single Serpentine: entry and exit at same level, up to 76 m (250 ft) of chain

- Dual Direction, Double Serpentine: entry and exit at same level, up to 76 m (250 ft) of chain

- Transfers:

- Side Plow

- X-Tranfer

- Roller Transfer

- Powered Transfer

Direction:

Direction is determined by the product, belt selection, and product rate.

- Incline: Product being produced starts at a lower elevation and is moved to a higher elevation

- Decline: Product being produced starts at a higher elevation and is moved to a lower elevation

Possible Applications:

- Product buffering during machine maintenance

- Use of vertical space when there is not enough floor space to accumulate more product

- Product movement at different levels

- Downstream product flow avoiding a bottleneck in your process

- Drying, cooling & curing time

- Product being produced needs more time for process or testing

- Product cycling/batching or to store product while another is being dispatched

- Reduce the forces working on a product when accumulating

- Serves as a walk thru/line access for product to divert onto

In-Line vs. Off-Line:

If an Alpine is to be used as a buffer, it needs to be determined if in-line or off-line is desired. If in-line is used, all normal production flow goes through the Alpine and would be accumulated upon a storage signal.

Typically, a stop device is required. Off-line has traffic flow around the Alpine and diverts into accumulation as needed.

Accessories

Belting

Support Stands

Gearmotors

Profiles & Guiding

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| FlexMove Engineering Manual | 244 | 55.2 MB |

| Literature | Pages | File Size |

| FlexMove Brochure | 6 | 2.9 MB |

| FlexMove Alpine Conveyor Spec Sheet | 10 | 3 MB |