3 FACTORS TO KNOW IN FOOD PROCESSING

A Guide to Boosting Overall Equipment Effectiveness with Sanitary Built Conveyors

Applications for Conveyors in Food Processing & Handling

Precision conveyors can add efficiency, speed, and improved food production and packaging accuracy. With the wide range of conveyor solutions, Dorner has to offer, we can design, build, and install conveyors for almost any application, including:

- Raw meat & poultry

- Dairy & cheese

- Fruits & vegetables

- Ready-to-eat foods

- Baked goods & confectionery

- Pet foods

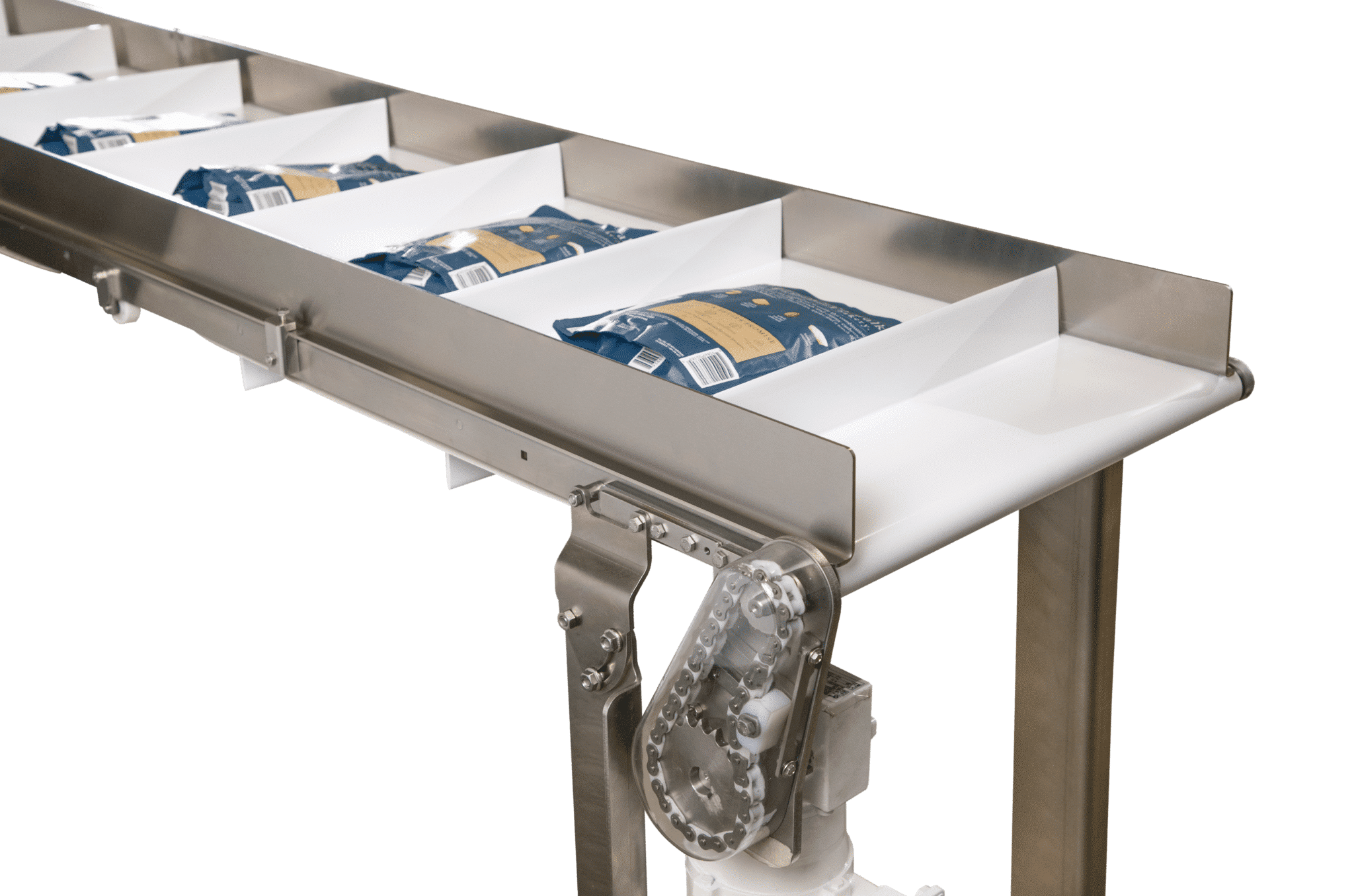

- Food packaging

- Candy & snacks

Ergonomic Cheese Positioning System

Dorner partnered with a cheese producer needing a system for accurately positioning large blocks of cheese to prepare them for packaging. Our Engineered Solutions Team helped design and build a unique solution for this application. This system utilizes a pneumatic 90° turn and bump turn to reposition cheese blocks between packaging stages. The automatic turning feature eliminates the need for staff to move the heavy blocks and provides a more ergonomic packaging process. Take a look at this system in action!

Ready for a new conveyor system?

PROJECT EVALUATION

Discovery

Proposal

Quote

EXPERIENCED ENGINEERING

Kick-off

Dedicated Team

Drawings

Delivery Schedule

SYSTEM MANUFACTURING & TESTING

Manufacturing

Testing

Shipping

FIELD START-UP

On-Site Start-Up

Troubleshooting

Customer Satisfaction

TRAINING & AFTERMARKET SUPPORT

On-Site Training

24/7/365 Service

Sanitary Conveyors

Ready-to-Eat Food Processing Conveyors

Ready-to-eat foods offer easy but nutritious meals and snacks for a fast-paced society. Because these products can go right from production to table, proper sanitation is vital to maintain the highest level of quality and keep consumers safe. Dorner’s RTE conveyor systems are designed with these hygienic requiremments in mind.

Hygienic Features

- FDA Approved belting and plastic materials

- Continuous TIG-welded 304 stainless steel frame

- Toolless disassembly for cleaning prep in under 1 minute

- Tip-up tails for quick belt release and retentioning

- Quick cleaning accessories such as belt lifters and clean-in-place modules

AquaGard GT: Tabletop Conveyors

As Dorner’s newest sanitary conveyor, the AquaGard GT offers flexibility and versatility in any food packaging and bottling application. With a flexible chain belt and low profile, stainless steel frame, this system is ideal for transferring product between steps in the line or as a tabletop conveyor within production processes.

Specifications

- Widths: 83, 115, 191, & 305 mm (3.25, 4.5,7.5, & 12 inches)

- Lengths up to 25,000 mm (82 ft) in 5 mm increments

- Loads up to 700 lbs

- Speeds up to 222ft/min

Ideal Applications

- Bottling

- Packaging

- Accumulation

- Main line conveyance

AquaGard LP: Quick-Clean Solution

The AquaGard LP is a low-profile, sanitary stainless steel conveyor rated for low pressure wash downs with soap and water cleaners. This system features tip up tails for quick belt cleaning and change overs, as well as a compact, enclosed tensioning system for easy maintenance. The streamlined design of the AquaGard LP allows this conveyor to fit where others do not, making it perfect for sanitary integration applications in pharmaceutical manufacturing facilities.

Specifications

- Widths from 70-457 mm (2.7-18″)

- Lengths from 500-5485 mm (19.7″-18′)

- Loads up to 22.7 kg (50 lbs)

- Speeds up to 75 mpm (246 fpm)

Ideal Applications

- Secondary packaging

- Baked goods & snacks

- Confectionery

- Dry pet foods

- Packaged foods

AquaPruf: High Pressure Washdown

Our AquaPruf series of sanitary stainless steel conveyors are rated for high pressure washdown and chemical sanitization applications. With quick clean accessories such as our tip-up tail design, belt lifter,s and frame cut outs, this conveyor system will cut down on line change over times and improve hygiene throughout your facility.

Specifications

- Widths: 152-1,524 mm (6-60 in)

- Lengths: 914-25,375 (36-999 in)

- Loads: up to 98 kg per square meter (20 lbs per square foot)

- Speeds: up to 100 mpm (328 fpm)

Ideal Applications

- Processed foods

- Primary packaging

- Fruits & vegetables

- Nutraceuticals

- Pet foods

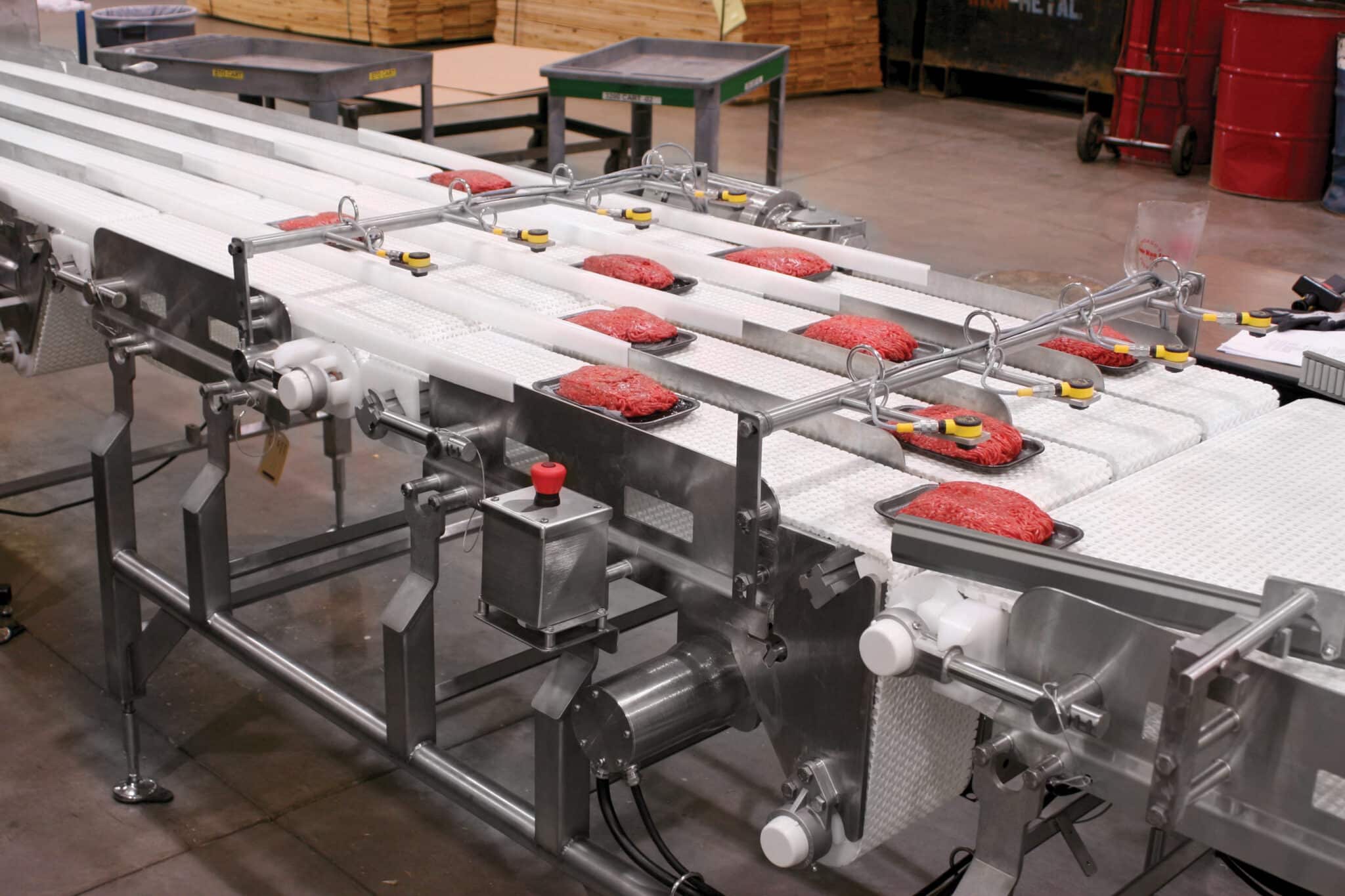

AquaPruf Ultimate: 3-A Certified

Dorner’s AquaPruf Ultimate offers the highest level of sanitation, and is 3-A certified for raw meat, poultry, and dairy. This conveyor system features all of Dorner’s quick clean accessories, as well as a higher weight rating and patented drive sprocket design for hygiene and durability. Additionally, the continuous TIG-welded frame and 32 microinch polish reduces the risk of contamination and debris buildup.

Specifications

- Widths: 150-1200 mm (5.9-47.3 in)

- Lengths: 915-25000 mm (36-984 in)

- Loads up to 341 kg (750 lbs) or 98 kg/sq m (20 lbs/sq ft)

- Belt speeds up to 78.6 m/min (260 ft/min)

Ideal Applications

- Raw meat & poultry

- Ready-to-eat foods

- Dairy & cheese

- Highly sanitary environments

AquaPruf VBT: Vertical Bulk Transfers

The final product in our AquaPruf line is the AquaPruf VBT, a vertical bucket conveyor system designed for bulk product elevation. The bucket belt system features a staggered wall design, minimizing product loss and maximizing efficiency. The frame cutouts and tip-up tail design also make cleaning and maintenance quick and easy.

Specifications

- Widths from mm (20-72″)

- Lengths from mm (16-240′)

- Speeds up to mpm (100 fpm)

- Staggered Sidewall Belt provides 15% more pocket capacity than traditional sidewall belt

Ideal Applications

- Candy

- Cereal & snacks

- Bulk dry goods

- Dry pet food

- Pharmaceuticals

Accumulation Tables from Garvey

In temperature-sensitive pharmaceutical production, any time out of the cold chain can negatively affect the potency of a product. One of the biggest contributors to the time pharmaceuticals are outside of the cold chain is in packaging and inspection, where products can be at room temperature for 24-48 hours.

With Garvey’s Automatic Vial Dryer, this time can be cut down to as little as 5 minutes! The modular design keeps the vial drying system flexible and easily configurable to fit into tight production layouts. It also includes various in-feed and out-feed options and can be customized to meet the needs of your production line.

Ready to Optimize Your OEE with a New Conveyor System?

Sign up for DTools to start configuring your custom conveyor.

OR

Contact us for a no-obligations quote!

Create your own custom conveyor with Dorner s industry leading CAD/Configurator software. With DTools, designing a conveyor that meets your specific application is quick and easy. Submit a request for complete custom systems or replacement parts for your existing conveyor, and get a free quote and CAD design fast!