AquaPruf Ultimate Conveyors

Dorner’s AquaPruf Ultimate conveyors are 3-A Certified. These product upgrades ensures that the AquaPruf Ultimate meets the strict requirements of 3-A and is optimally designed for use in food applications such as meat, poultry, fish and ready-to-eat.

AquaPruf Ultimate Features

- All surfaces on internal frame components are polished to 32 microinch, except belted product.

- All bearings are external to the conveyor and a minimum of 25 mm away from the food zone.

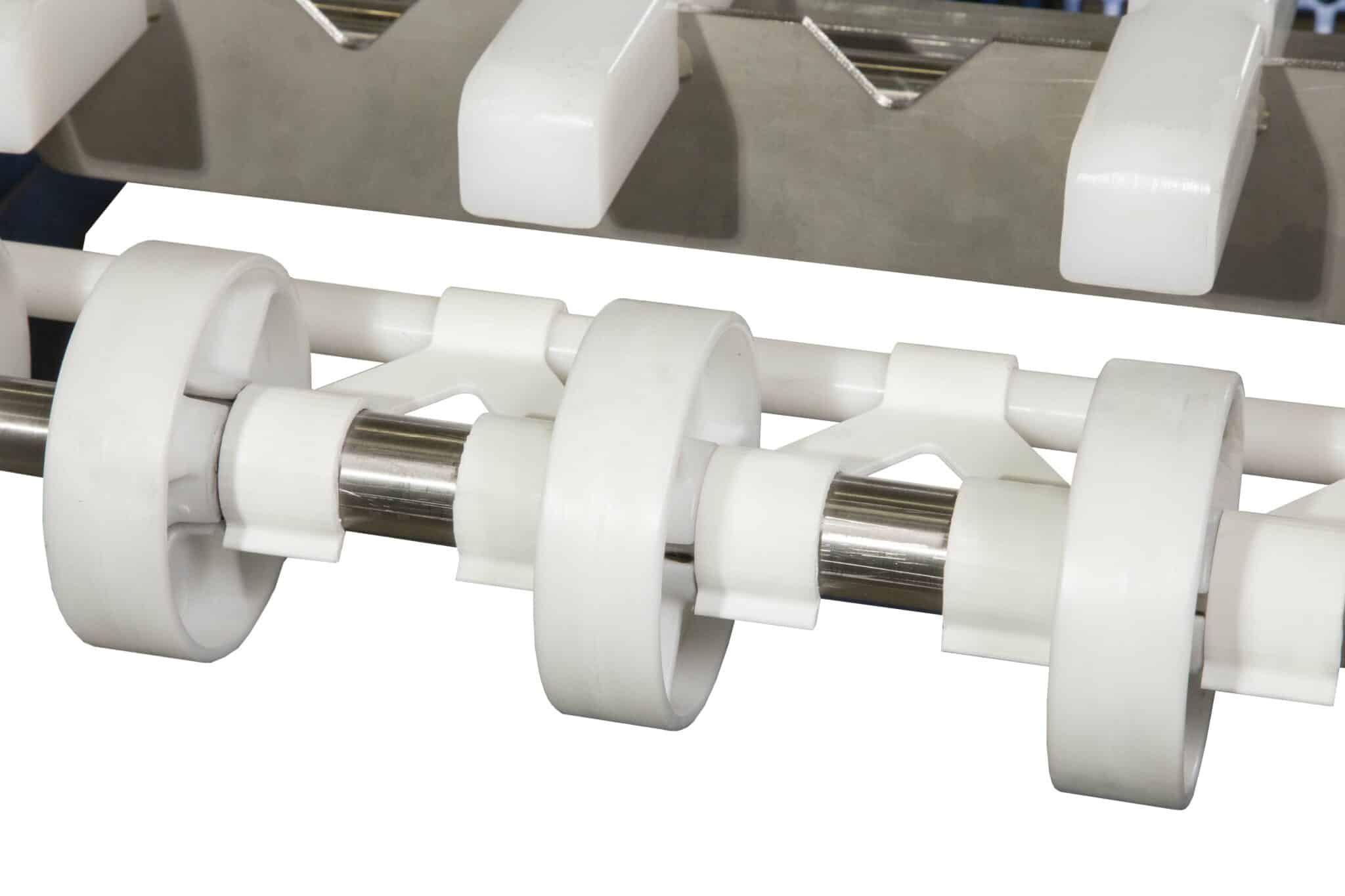

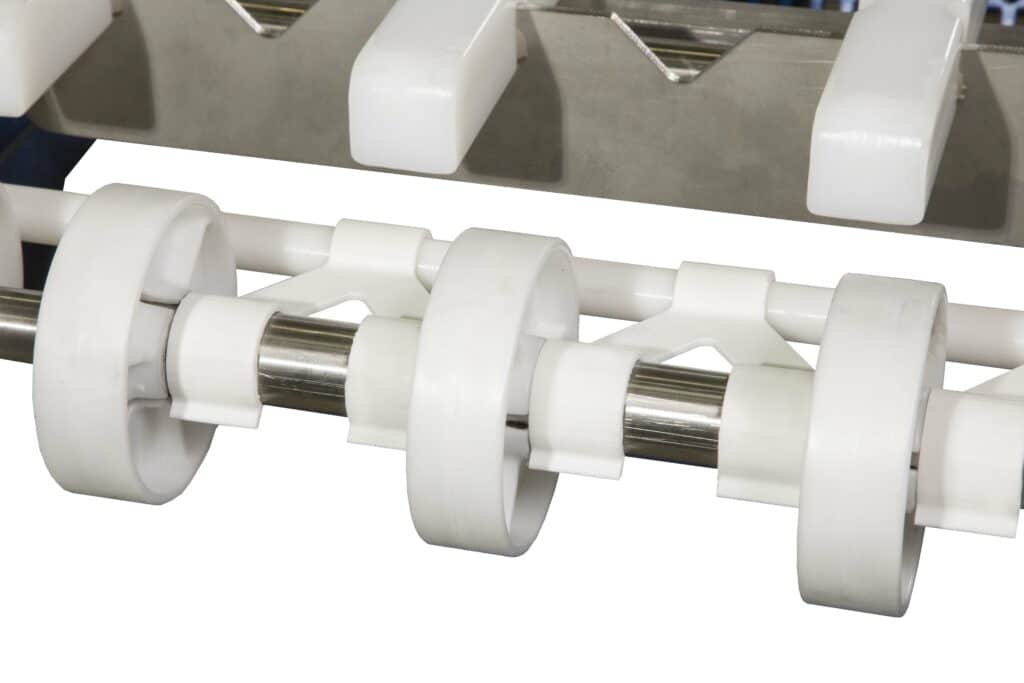

- Drive sprocket design includes a quick cleaning system to ensure cleaning can be done below the sprocket surface.

- Patent pending idler tail cleaning system on Modular Belt and Positive Drive Belt models.

- Belting / Chain offered meet strict 3-A, and USDA requirements.

- All support stands use only sanitary threadless feet designs.

- Radii on all internal components meet the 6 mm (0.25″) standard requirement.

- Conveyor cleaning guideline is provided specifically for effective cleaning of the Dorner product.

Conveyors Available as AquaPruf Ultimate:

Benefits of AquaPruf Conveyors:

- Tool-less disassembly. Cleaning prep in under a minute, complete disassembly in less than 3 minutes

- Optional frame cut-outs and belt lifters for continuous access to inside of the conveyor

- Tip-up tails allow for quick release of belt tension

- Continuous TIG-welded 304 stainless steel frame

- Spiral cam belt tensioning with patent pending thread-less design

- Patented sprocket alignment key

- Gearless, oil-free iDrive2 sanitary motorized roller

- Manuals & Literature

- Accessories

- Profiles

- Fabric Belting

- Modular Belting

- Support Stands

- Gearmotors

- Drive Mount Packages

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| AquaPruf Engineering Manual | 76 | 9 MB |

| Literature | Pages | File Size |

| Sanitary Conveyors Brochure | 6 | 5.97 MB |

Accessories

Profiles

Fabric Belting

Standard Belting

Note: Wet applications are limited to specialty belt types 54, 55, 69 and 70 only.

Specialty Belting

Note: Wet applications are limited to specialty belt types 54, 55, 69 and 70 only.

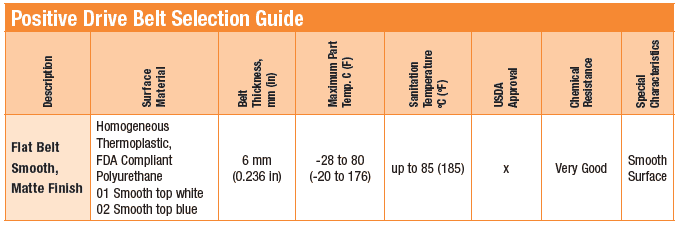

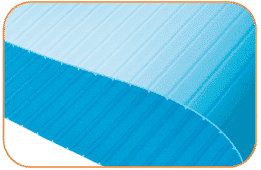

Positive Drive Belting

Specifications:

- Solid Urethane material

- Drive lugs on 25 mm (1 in) spacing

- Available in Blue or White

- Excellent abrasion and tear resistance