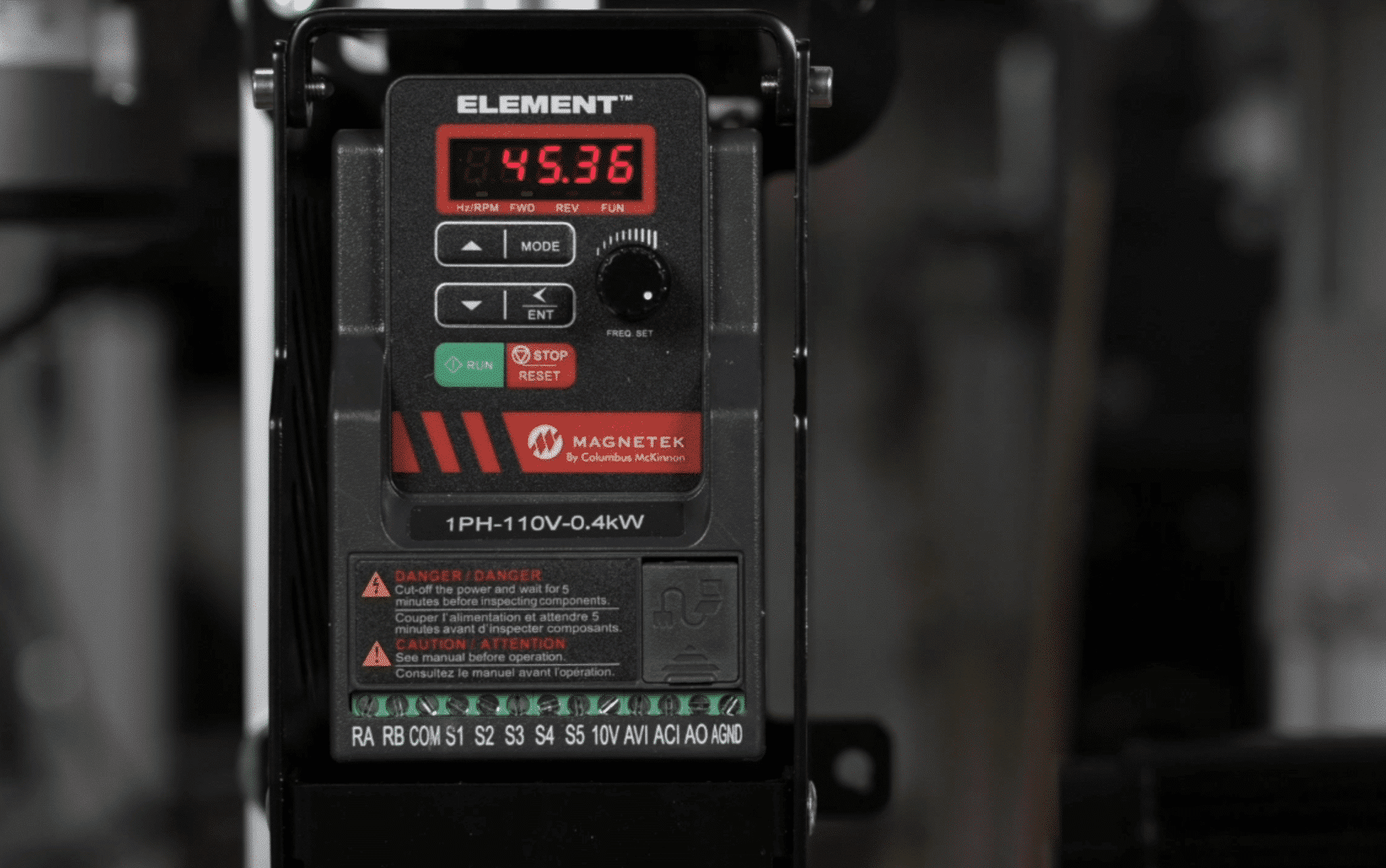

Magnetek Element VFD Controller

Benefits & Features of the Magnetek Element VFD

The new Element VFD is an easy-to-use “plug and play” controller perfectly designed to control Dorner’s low-profile conveyors in indoor factory environments. When ordered with a complete conveyor package, this controller is factory-set to match the accompanying motor and conveyor settings, with the potentiometer set to control speed (frequency) and parameters locked to prevent accidental parameter changes. If the VFD is ordered separately or as a spare part, the motor parameters must be set in the field.

Using the Quick Start Guide, the Element is easy to set up and reconfigure to meet changing requirements in a production line. This VFD can also be configured to take i/o and includes 5 digital and 2 analog inputs, as well as 1 digital and 5 analog outputs for use as needed.

Conversion Chart

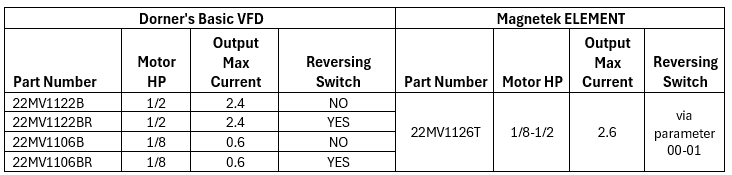

This VFD will replace some of Dorner’s current standard VFDs. See the chart below for details on the part conversion for these VFDs.

Manual & Guides

| Manuals | Pages | File Size |

| Quick Settings Manual | 122 | 7.8 MB |

| Quick Start Manual | 78 | 8.5 MB |

Tutorial Videos

Unlocking & Locking the VFD Controller

Changing the Conveyor Direction

Identifying & Changing Parameters

FAQ

Frequently Asked Questions

Does the VFD have safe torque off?

NO, the Magnetek Element is not equipped with a no torque off terminal.

What is the short circuit current rating?

Circuit breaker current rating should be 200mA or above, and operating 0.1 sec or longer.

How/Where to mount VFD?

The VFD enclosure is designed to be mounted directly on Dorner conveyor’s T-slots. Follow the Service Manual for more details. This VFD package is not intended to be inside an electrical enclosure. If VFD’s are to be mounted inside an electrical enclosure, the metal shroud must be removed.

What is the environmental rating of the VFD?

The VFD carries an IP 20 rating, in addition, the metal enclosure around the VFD allows it to be touch-safe and provides field wiring strain relief.

Can this VFD be used with European power (50Hz)

This VFD can be utilized for 100-120V single-phase 50Hz input power. Furthermore, motor parameters can be set to control 220V 50Hz motors.

How to reverse motor direction?

The VFD’s default parameter controlling motor direction is set to “0-forward”. When installing the VFD for the first time Dorner recommends wiring the 3-phase power of the motor so that when the VFD/motor is powered, the indented direction is achieved. During installation, if the conveyor runs in the opposite direction, power off the system and swap one of the motor connections which will change the motor direction.

When the direction of the motor must be changed outside of the initial installation, use the parameter 00-01 and select either 0-forward or 1-reverse. Multifunction I/O can also be used to change direction remotely.

What model number do I use to replace my old Dorner Basic VFD?

Dorner’s old Basic VFD options are based on application variables 1. Current capacity, 2. Reversing or not reversing. The Magnetek Element VFD will be able to replace all 4 versions of Dorner’s

VFD with one model number. However, reversing of the conveyor will be done via a parameter. Below is a conversion chart:

| Dorner’s Basic VFD | Magnetek ELEMENT | ||||||

| Part Number | Motor HP |

Output Max Current |

Reversing Switch |

Part Number | Motor HP | Output Max Current |

Reversing Switch |

| 22MV1122B | 1/2 | 2.4 | NO | 22MV1126T | 1/8-1/2 | 2.6 | via parameter 00-01 |

| 22MV1122BR | 1/2 | 2.4 | YES | ||||

| 22MV1106B | 1/8 | 0.6 | NO | ||||

| 22MV1106BR | 1/8 | 0.6 | YES | ||||

Is it possible to extend or replace the VFD input and output wires?

The ELEMENT VFD comes pre-wired with 10 feet of wire on both the input and motor connections. If replacing the cable, please consult NEC for the proper conductor size by the desired length.

- Output cable: SOOW, 4 conductor, 18AWG, flying leads for motor connection

- Input cable: SJTOW, 3 conductor, 16AWG, conventional North American 3 prong Plug

Is the VFD UL or CSA compliant?

YES, the VFD carries a cULus listed mark. This means the product is compliant with UL and CSA standards.

How to set motor parameters?

The Element basic conveyor VFD is shipped from Dorner’s factory with motor parameters pre-configured for its intended motor. In situations where the VFD is a replacement part, motor parameters can be changed follow the manual and video for details.

Download VFD Controller Manual

How to unlock the VFD

As an effort to simplify the controller function the product parameters are locked however it can be unlocked by setting the parameters below.

| Number | Description | To unlock set to | Factory Default |

| 13-06 | Parameter Lock | 0-Enable all functions | 3-Disable all functions |

How to revert to default settings?

The VFD is factory set and locked; however, if reverting to factory settings is necessary, several saved settings can be accessed via parameters 13-08.

Note: Motor parameters (02-XX group) will need to be set for the specific motor the VFD is controlling after the factory reset is enabled.

What type of circuit is needed to run the VFD/conveyor?

The VFD is required to be connected to a fused disconnect or a circuit breaker. DO NOT connect VFD to a GFCI (Ground Fault Circuit Interrupter) circuit it could cause nuisance tripping.

Each VFD has a maximum current draw of 13 amps, a 15 amp circuit is suggested for each VFD. Consult NEC and local electrical code for circuit sizing requirements.