- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

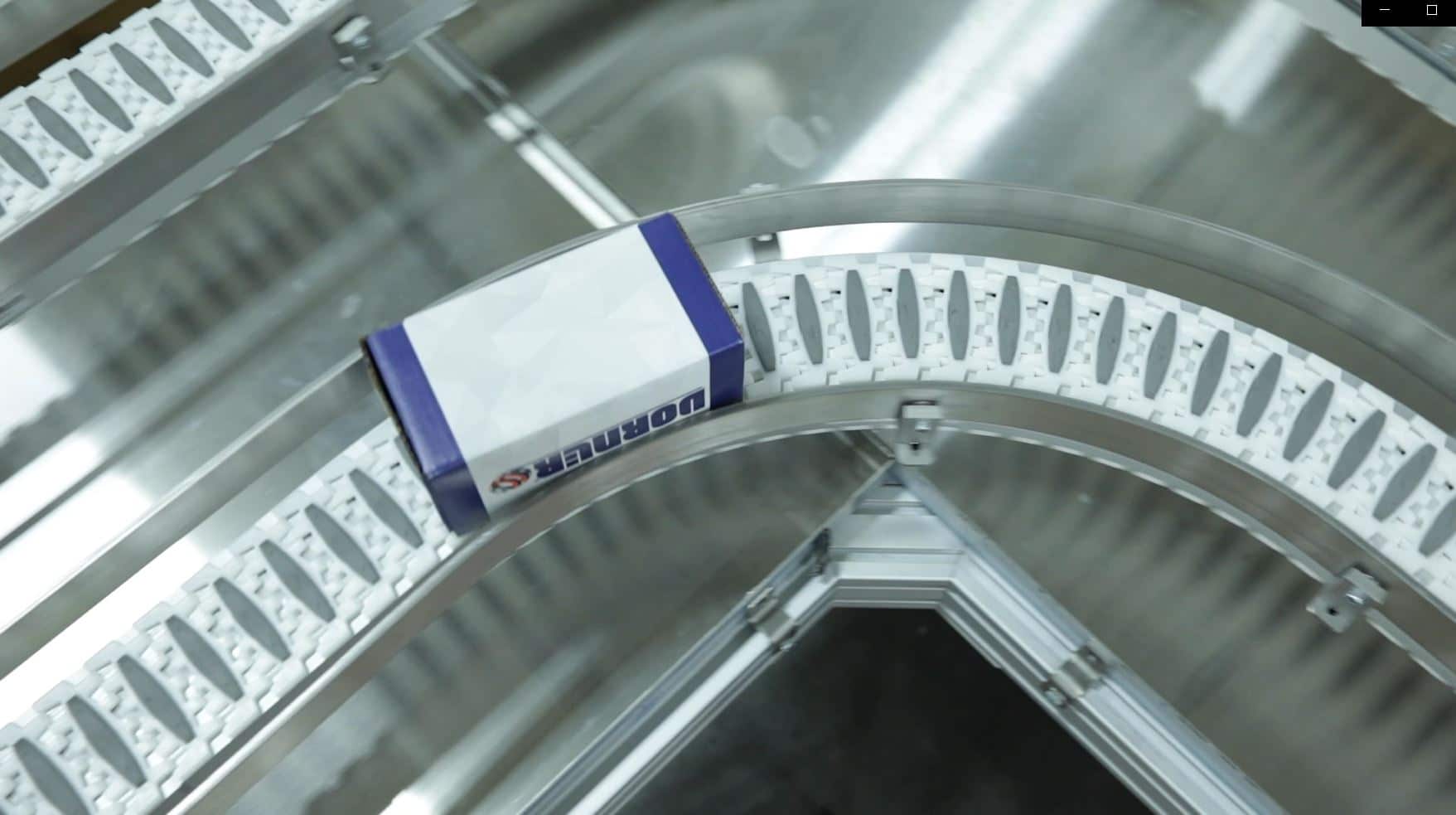

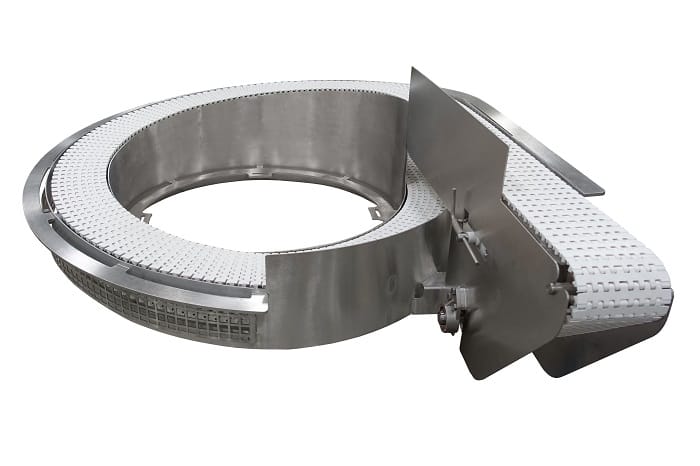

Cosmetic Conveyors

Customized Conveyor Systems for Packaging Cosmetics

Dorner’s Conveyor Solutions for Cosmetic Products and Beyond

No matter what type of cosmetics or pharmaceutical products you need to move, we can create efficient production and packaging systems with integrated conveyors, accessories, and controls to help you meet your manufacturinggoals.

Machine Integration and Lab Work

Packaged Goods

Packaging and Sorting Cosmetics

Sanitary Manufacturing

Bottling and Packaging

Special Considerations for Manufacturing Cosmetics

Gentle Handling Features to Prevent Damage

Hygienic Materials and Easy-Clean Features

The personal care and cosmetic industry requires that facilities adhere to extremely strict hygiene and sanitation regulations.With the passage of the Modernization of Cosmetics Regulation Act(MoCRA) in 2022, cosmetics manufacturers face new regulatory requirements that will impact production. Companies must comply with additional rules around facility registration, product listing, safety substantiation, good manufacturing practices, and labeling.

How Cosmetic Conveyors Can Streamline Your Manufacturing Process

Reduced Labor Costs

Increased Speed and Efficiency

Improved Productivity and Profitability

Consistent Output with Minimal Errors

Choose Dorner for Your Cosmetic Conveyance Needs

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy