Applications

Rotating Conveyors

The use of a rotating conveyor in your facility can improve productivity and ensure proper product handling. By reorienting products with a rotating conveyor, you can expedite the manufacturing process without compromising accuracy and care. In addition, rotating conveyors can save valuable floor space.

Types of Rotating Conveyors

With conveying solutions from Dorner, you can rotate products 90, 180, 270, or 360 degrees to enable efficient handling and accurate processing. There are several different types of rotating conveyors to manage various rotation and reorientation needs.

Flipping

With conveying solutions from Dorner, you can rotate products 90, 180, 270, or 360 degrees to enable efficient handling and accurate processing. There are several different types of rotating conveyors to manage various rotation and reorientation needs.

Lifting and Rotating

With a lift and rotate module, conveyors can efficiently rotate products without disrupting the manufacturing process. Conveyors with this feature simply lift the product or pallet above the belt and rotate the surface on which the product rests, effectively rotating it 90, 180, 270, or 360 degrees as needed.

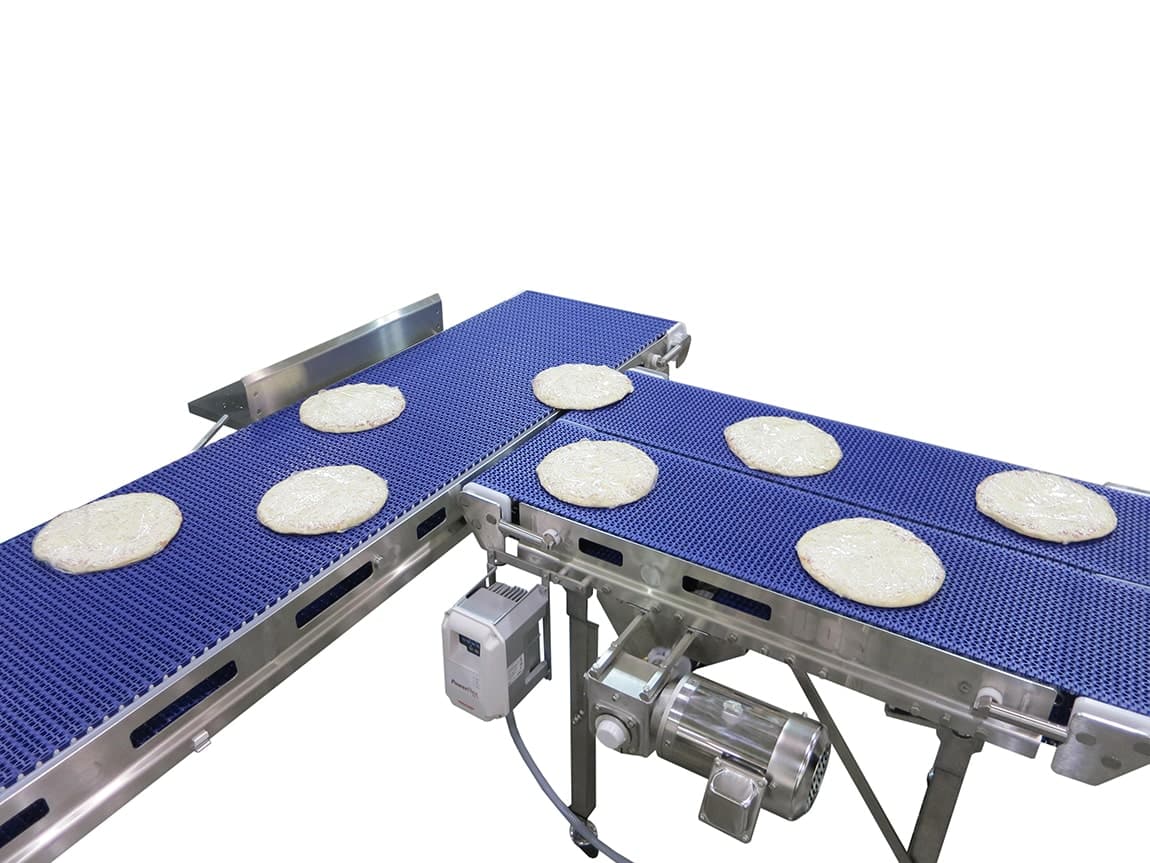

Transfering

While transferring processes does not always involve rotation, production lines often find that transferring and rotating products at once is an efficient practice. You can effectively transfer products from one system to another while rotating them for increased surface access through the following methods:

- 90 degree transfer

- Side transfer

- Inline transfer

- Nose bar transfer

- Powered transfer modules

Accumulation

Designed to save space and facilitate product organization or supply, accumulation conveyors can also be used to rotate products. Rotations accomplished by accumulation tables can help ensure all products have been manufactured or assembled correctly. Additionally, accumulation conveyors can rotate products so that they are best prepared for the next step, maximizing efficiency and productivity.

Benefits of Using A Rotating Conveyor Belt

With rotating conveyor belts from Dorner, your manufacturing process can achieve new levels of efficient, precise operation.

Automation

Conveying solutions from Dorner can be easily automated, providing enhanced accuracy and efficiency while also cutting costs. With automated rotating conveyors, you can also achieve higher standards of safety by reducing the need for dangerous equipment like lift trucks. Automation can increase production and promote optimal functionality across all processes, and integrating a rotating conveyor belt from Dorner will allow you to achieve these high standards of operation.

Product Positioning

The use of a rotating conveyor provides efficient, accurate product positioning at any point in the manufacturing process. Rather than rely on human workers to position products, a rotating conveyor can accomplish this task automatically without error, promoting higher production rates and consistent products.

Precision

Rotating conveyor belts increase the accuracy of reorientation efforts, ensuring products are properly positioned for next steps. With an automated rotating conveyor belt, you can trust that all products will be precisely positioned before moving forward, ensuring accurate labeling, assembly, packaging, and more.

Dorner Conveying Solutions to Rotate Product

Dorner offers specialized rotation solutions to address your needs. Depending on the products you work with, the space you have available, and any other limitations or needs, our team can provide you with a customized solution for rotating products.

Dual Conveyor Product Turner

FlexMove Conveyors

FlexMove conveyors from Dorner offer innovative, flexible solutions to help you maximize the manufacturing potential of your business. Conveyors from the FlexMove series are ideal for a variety of rotation applications including:

- Assembly

- Transfer

- Accumulation

- Packaging

FlexMove Twist

Designed to optimize product rotations, the FlexMove Twist conveyor is equipped with flexible chain for efficient, precise product handling. With a FlexMove Twist conveyor, you will have:

- Enhanced product control

- Accurate product rotation for increased access

- Automated product management

- No need for product guiding, gapping, or spacing

Lift and Rotate Conveyors

Lift and rotate modules on Dorner conveyors can provide optimal precision for operations such as inspections and assembly.

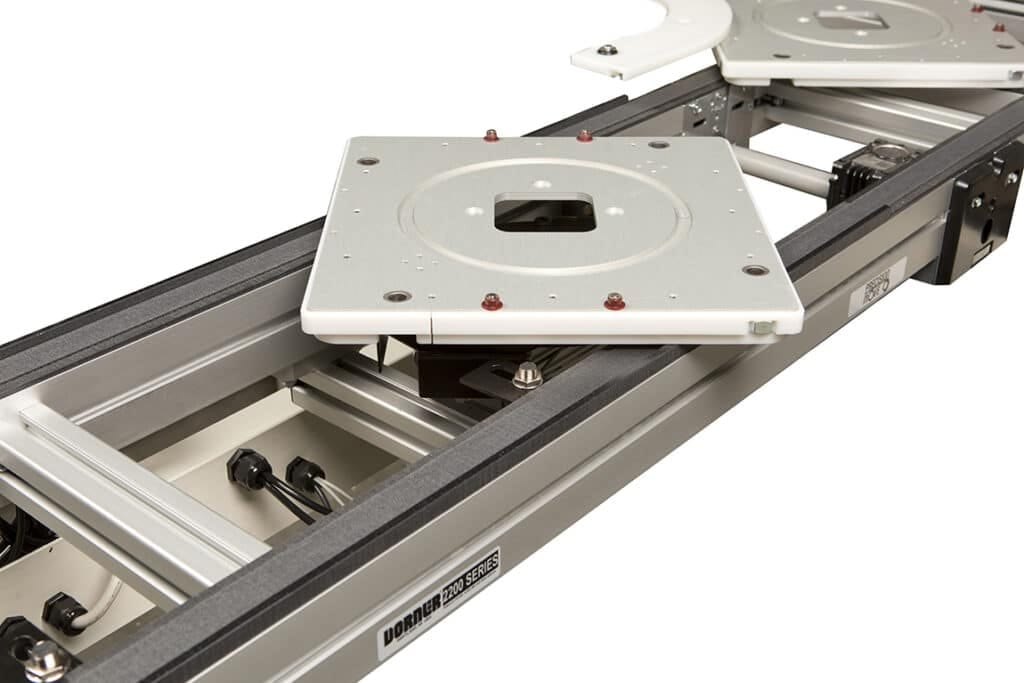

2200 Precision Move Pallet System Lift and Rotate Module

With the lift and rotate module on our 2200 Precision Move Pallet System, you can effectively lift and rotate products weighing up to 200 lbs. by 90 to 180 degrees. Heavy, bulky products that require multi-side access during production, assembly, or packaging are easy to rotate with this module.

Bump Turns

The simplest and most cost-effective rotation solution, bump turns can effectively rotate products 90 degrees, with additional bumps available to continue the rotation. Bump turns are especially useful for rotating boxes and crates, and they are available as fixed or adjustable installations.

Conveyor 90 Degree Transfer

Transporting products safely and efficiently is a top priority across industries, and with a 90 degree conveyor transfer, you can easily facilitate a safe transfer while also orienting the product effectively for the next process.

Whether you are transferring products onto another conveyor belt or onto a different piece of equipment, completing a right angle transfer with the appropriate conveying solution can optimize your processes and ensure products are safe and accessible.

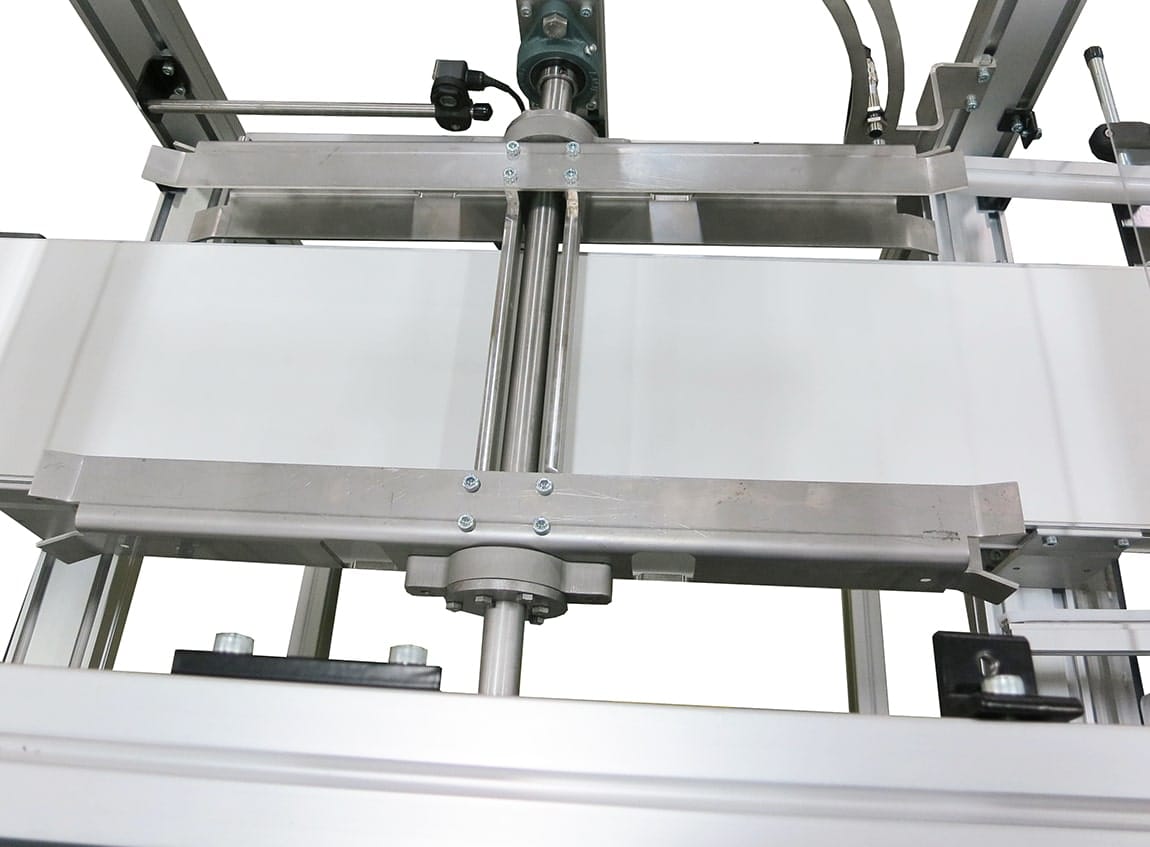

Flippers

Flippers are effective at granting access to the undersides of products for sealing, labeling, and preparation processes. Using a flipper is an efficient and precise way to safely handle products during the manufacturing and packaging processes.

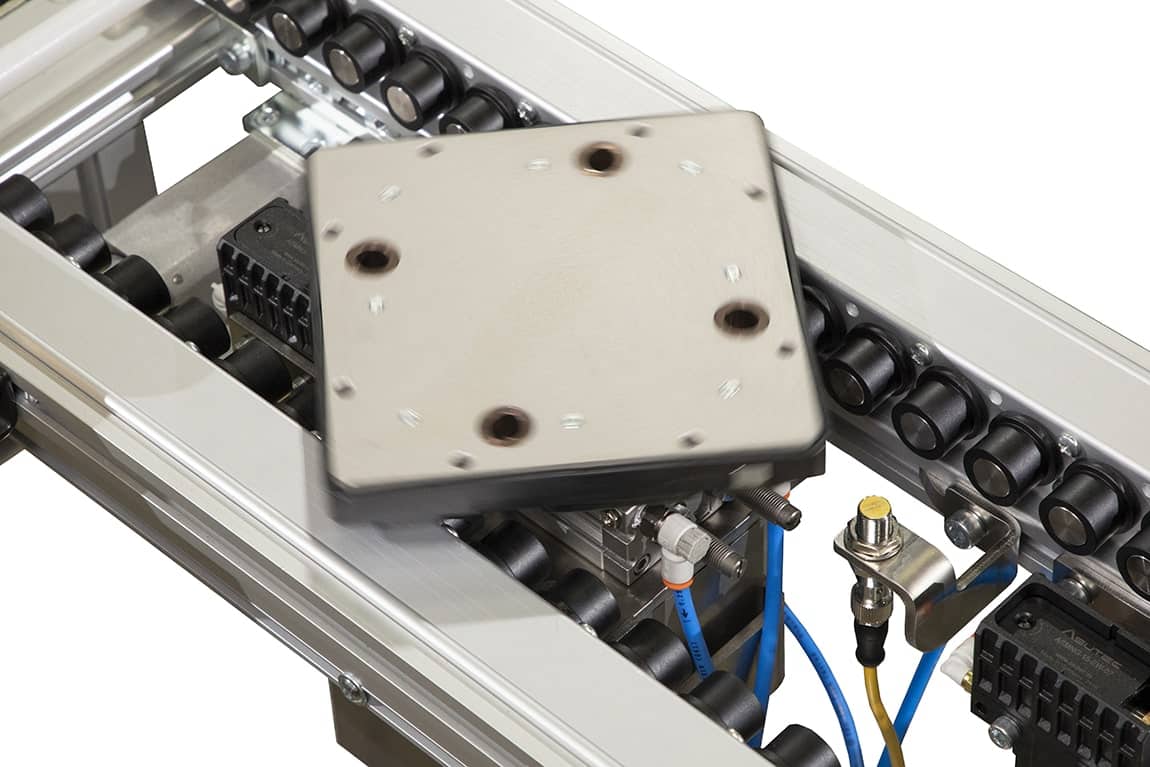

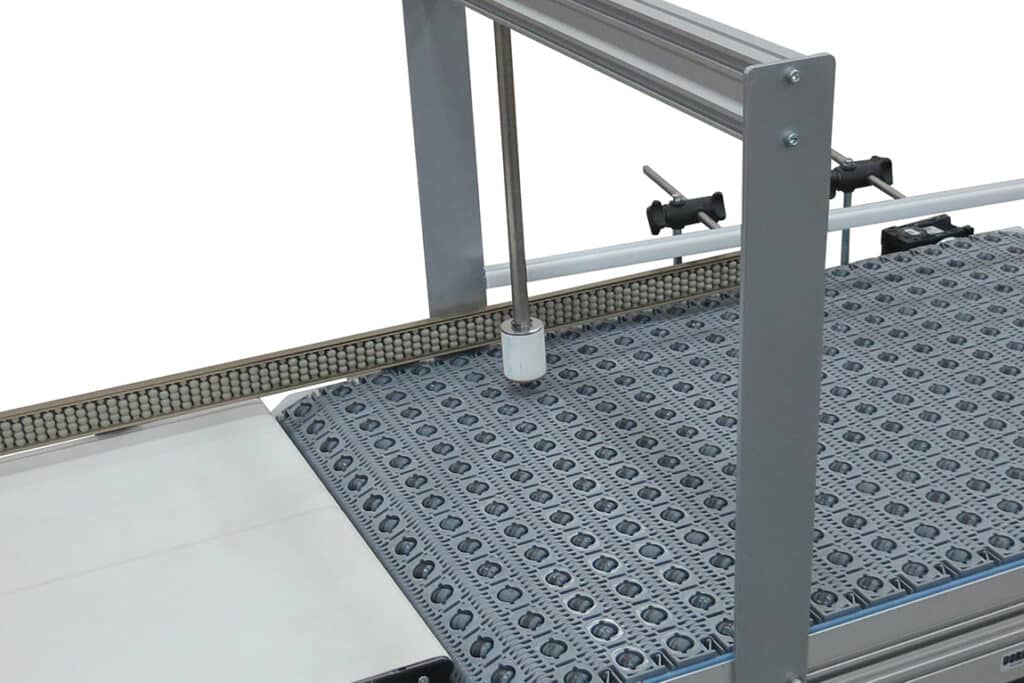

Edge Rollers

The use of edge rollers like the ERT150 from Dorner provides frictionless pallet handling, ideally suited for small and light-load assembly automation. Edge rollers can provide increased flexibility in product handling, allowing for traffic control and non-contact zones. During operation, edge rollers can be automated to rotate products and pallets for practices such as:

- Lift and transfer

- Lift and rotate

- Lift and locate

- Turn and transfer corner

Industrial Applications of Rotating Conveyor Belts

E-Commerce

Inspection & Testing

Ensuring products meet production standards is a critical part of most manufacturing operations, and rotating conveyors can help facilitate efficient and effective inspection and testing practices. With the use of an automated rotating conveyor, inspections and tests can be performed without issue by ensuring all products are identically oriented, allowing for efficient and accurate assessment.

Packaging OEE

Striving for high packaging overall equipment effectiveness (OEE) is a common goal, but achieving it can be a challenge. Determined by the availability, performance, and quality of equipments’ operations, packaging OEE requires precision, optimization, and adaptability.

Automated rotating conveyors from Dorner provide the flexibility necessary to increase OEE and overall success. With space-saving solutions designed to improve efficiency and accuracy, rotating conveyor belts from Dorner can enhance your operations and boost your OEE, resulting in higher standards of production and profitability.