The next evolution in Dorner’s Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications*. Earning the ISO Standard 14644-1 Class 4 rating* means Dorner’s ERT150 will conform and not contribute to the contamination of cleanrooms to those standards.

As implied by its name, the ERT150 uses rollers to move pallet conveyors smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor’s open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming.

The ERT150 is suited to operate in cleanroom environments* requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including:

- Medical and medical devices

- Electronics

- Consumer goods

The rollers are driven by a patent-pending, energy efficient linear gearbox that gives customers added flexibility with motor positioning and zoning. This allows for zone and slip roller operation. Simply removing a lower gear creates independent zones. The non-contact zone control provides simplified traffic control that eliminates pallet stops and costly pneumatic valves. Conversely, slip rollers can be used for full length runs with conventional pneumatic pallet stops. The rollers are easily accessible and can quickly be replaced without affecting the remaining portion of the conveyor.

Technical specifications of the new ERT150 include:

- 24 mm (0.95 in.) diameter rollers on 32 mm (1.36 in.) centers

- 80 mm (3.15 in.) to 480 mm (18.9 in.) wide

- Standard pallet widths from 160 mm to 320 mm wide

- Lengths from 128 mm to 2,432 mm in 64 mm increments

- Conveyors longer than 1,216 mm contain two gearmotors

- Loads up to 35 pounds per pallet or tray

- Speeds up to 37 m/min (121 feet per minute)

- Driven rollers for indexing / zoning and transport applications

- Slip rollers for low back pressure accumulation

- Brushless DC gearmotor and controller

- Gearmotor can be located at multiple locations along length on 128 mm increments

- Bi-directional and reverse movements

- Outer frame cover: flush design or flexible T-slot options available

- Clear anodized aluminum framing

- Electrically conductive polyamide rollers

- Automation modules

- Lift and transfer

- Lift and locate

- Lift and rotate

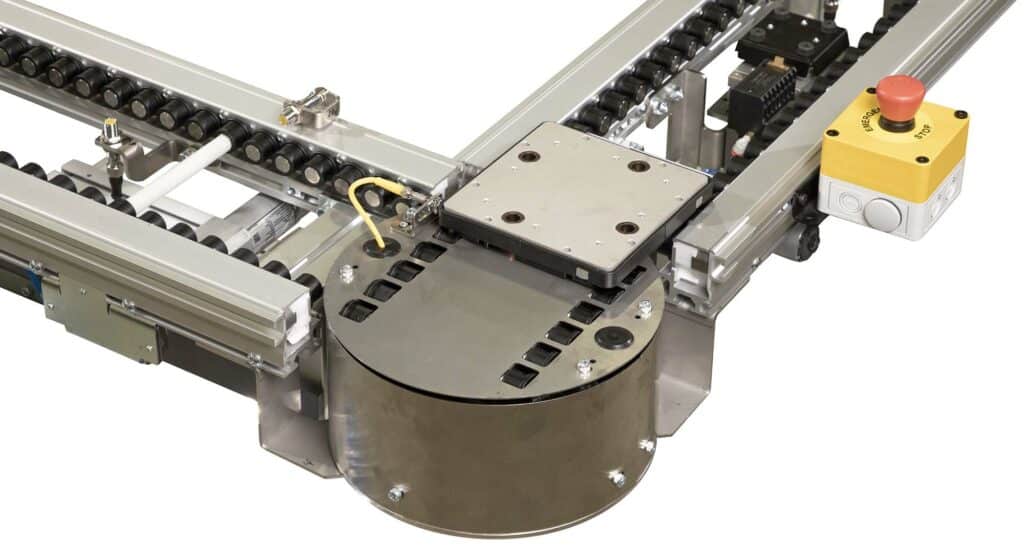

- Turn and transfer corner

- Pallet pusher

Learn more about Dorner’s ERT150 Conveyors.

*To verify clean room requirements, an unloaded base conveyor was tested and did not generate particulate that would be beyond the specified standards. However, the verification does not provide assurance that any or all applications will meet this requirement. Application testing is recommended to ensure clean room standards are being met. Dorner takes no responsibility in the clean room performance of the final conveyor or application.