- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Modular and Fabric Belt Conveyors

50+ Years of Innovation, Unmatched Customization, Industry-Leading Efficiency

Key Benefits of Modular and Fabric Belt Conveyors

Increased Productivity: Experience enhanced production capacity and increased throughput with our precision-engineered conveyor systems.

Enhanced Efficiency: Streamline operations with precise product handling, reducing bottlenecks and minimizing downtime.

Customizable Designs: From unique dimensions to specialized features, we tailor every conveyor to your exact specifications.

Versatile Applications: Whether you need straight, curved, or LPZ (Z-Frame) configurations, we have the perfect solution for your production line.

Overview of Dorner Belt Conveyors

The Dorner Difference: Our relentless pursuit of innovation and quality has made Dorner a trusted name in precision conveyors for over half a century. When you choose Dorner, you’re investing in a legacy of excellence.

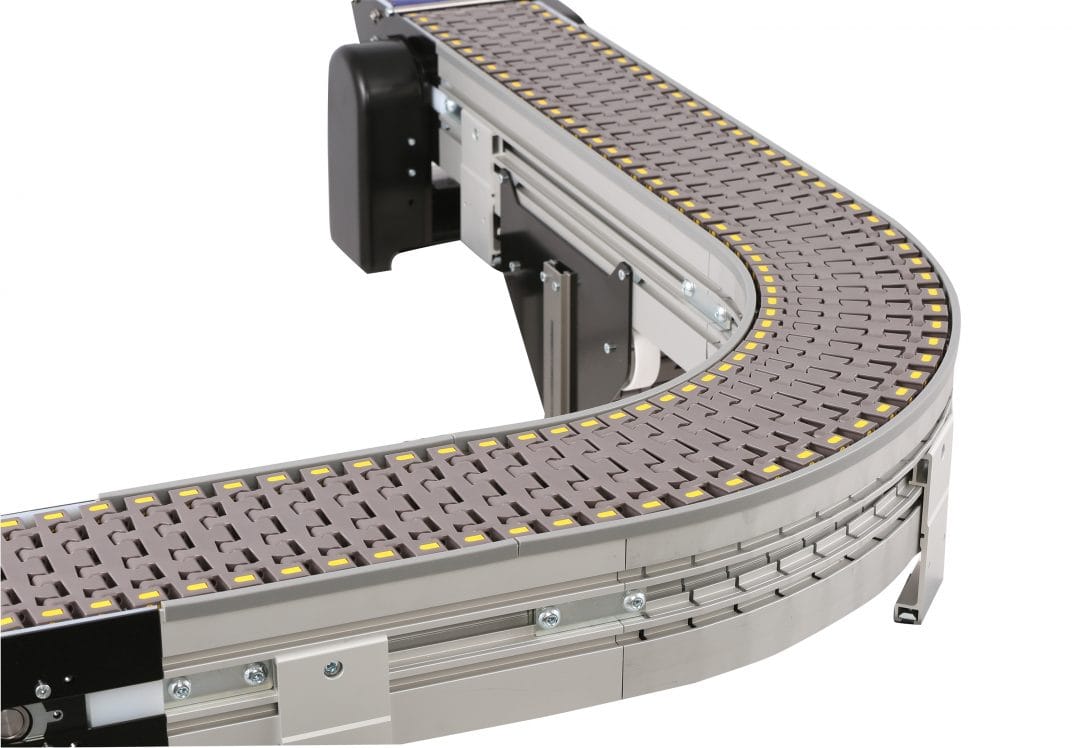

Modular Belt Conveyors

Key features:

- Easy maintenance with quick-release belt designs

- Extended belt life due to high-quality materials

- Various material options to suit diverse applications

- Flexible configurations for complex production layouts

2200 Series Conveyors

Key Specifications:

- Available configurations: End Drive, Center Drive, and iDrive models

- Belt options: Open mesh, closed mesh, and cleated chain

- Width range: 3" (76 mm) to 24" (610 mm)

- Length range: 18" (457 mm) to 30' (9,144 mm)

- Load capacity: Up to 150 lbs (68 kg)

- Maximum speed: 250 ft/min (76 m/min)

Configurations:

- Straight belt conveyors

- Modular belt conveyors

- Precision move conveyors

- Curved conveyors

- Z-frame (LPZ) conveyors

Belt Options:

- Fabric belts: Smooth, textured, cleated, or perforated

- Modular belts: Flat top, flush grid, or raised rib

Applications:

- Small part handling in electronics manufacturing

- Consumer goods packaging and processing

- Pharmaceutical product conveying

- Light assembly operations

- Automated inspection systems

3200 Series Conveyors: Heavy-Duty Performance

Key Specifications:

- Width range: 6" (152 mm) to 48" (1,219 mm)

- Length range: 36" (914 mm) to 999" (25,375 mm)

- Load capacity: Up to 1,000 lbs (455 kg)

- Maximum speed: 400 ft/min (122 m/min)

Configurations:

- Straight belt conveyors

- Modular belt conveyors

- Precision move conveyors

- Curved conveyors

- Z-frame (LPZ) conveyors

Belt Options:

- Fabric belts: Wide range of materials for various applications

- Modular belts: Plastic or metal options for diverse industry needs

Applications:

- Automotive parts handling

- Bulk product conveying in distribution centers

- Heavy-duty packaging operations

- Metal stamping part removal

- Robotic pick-and-place integration

Precision Move Conveyors

Key features:

- Tight tolerances for precise product placement

- Advanced indexing capabilities for automated processes

- Repeatable movement for consistent quality control

- Integration with robotics and vision systems

2200 Series Precision Move

Key Specifications:

- Width range: 1" (25 mm) to 24" (610 mm)

- Length range: 18" (457 mm) to 30' (9,144 mm)

- Load capacity: Up to 200 lbs (91 kg)

- Maximum speed: 370 ft/min (113 m/min)

- Mechanical accuracy: +/- 0.02"

- Servo motor index accuracy: +/- 0.04"

3200 Series Precision Move

Key Specifications:

- Width range: 4" (95 mm) to 18" (457 mm) in 2" increments

- Length range: 2' (610 mm) to 50' (15,240 mm)

- Load capacity: Up to 750 lbs (340 kg)

- Maximum speed: 517 ft/min (158 m/min)

- Index repeatability: ± 0.02" with servo motor package

- Performance rating: Up to 100 indexes per minute

Customization Options for Both Series:

- Belt-mounted fixtures for securing pallets or products in automated processes

- Custom guiding and transfer options for seamless product handling

- Integration with Dorner's controls solutions for automated operation

- Specialized coatings and materials for unique application requirements

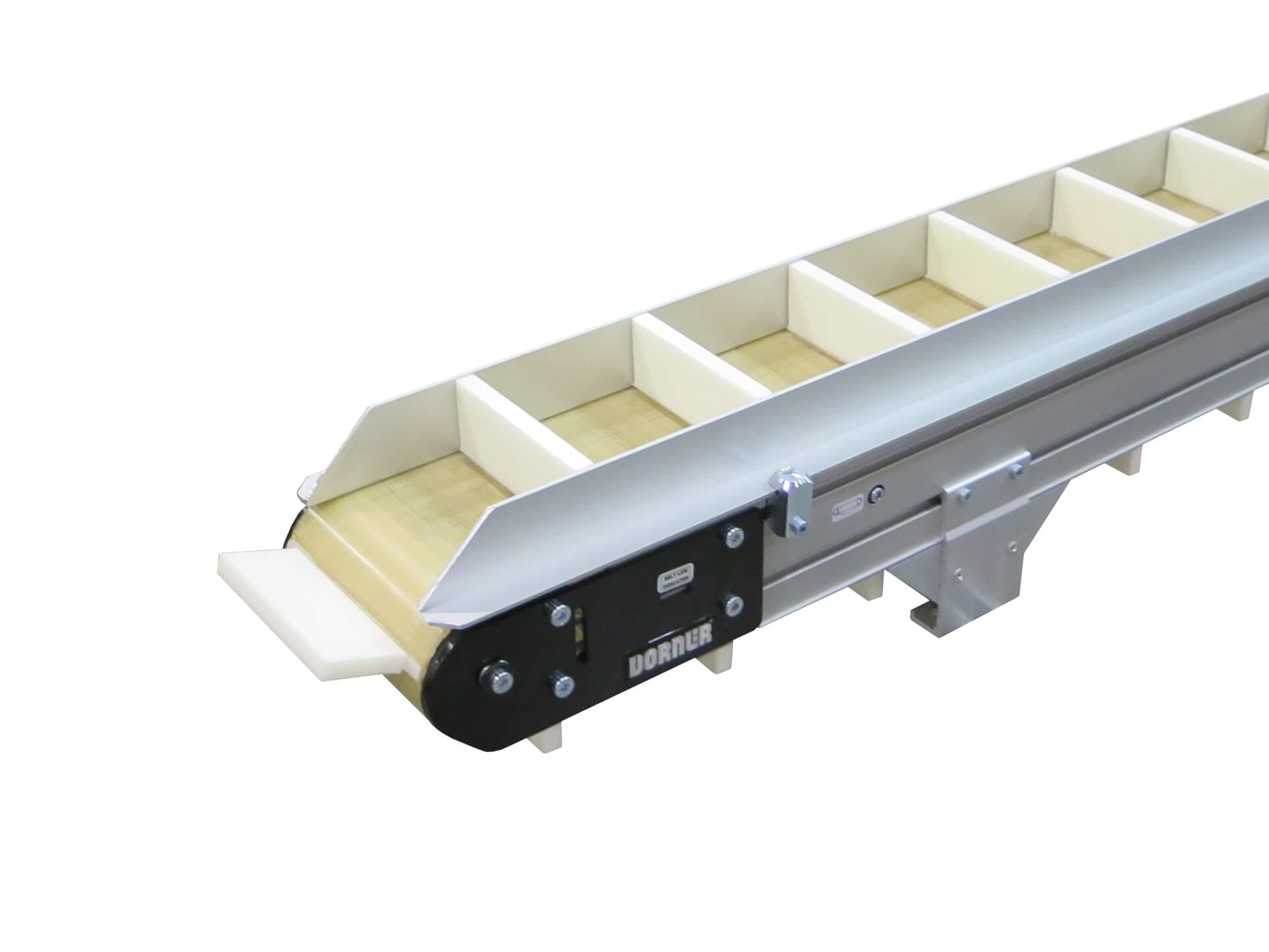

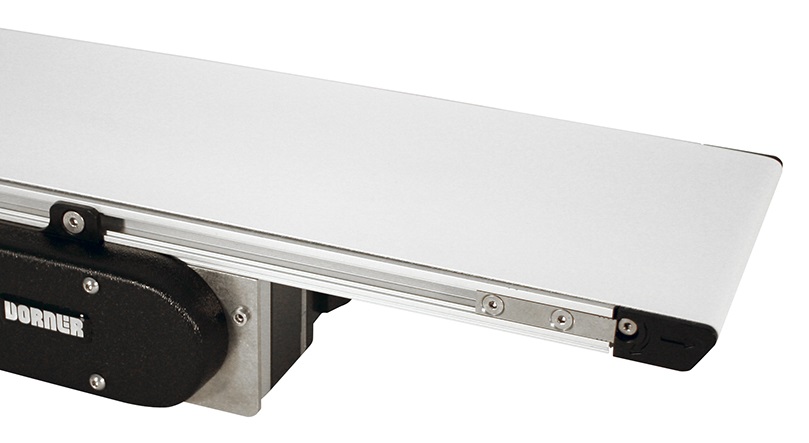

Fabric Belt Conveyors

Key features:

- Smooth product transfer for delicate items

- Quiet operation for improved workplace ergonomics

- Multiple belt material options for optimal performance

- Precision tracking for consistent product positioning

1100 Series

Key Specifications:

- Width options: 1.75" (44 mm), 3.75" (95 mm), 6" (152 mm), 8" (203 mm), and 10" (254 mm)

- Length range: 10.63" (270 mm) to 72" (1,829 mm) in 1/8" (3 mm) increments

- Load capacity: Up to 15 lbs (6.8 kg)

- Maximum speed: 80 ft/min (21 m/min)

Ideal Applications:

- Medical device assembly

- Electronics manufacturing

- Laboratory automation

- Pharmaceutical processing

- Small parts handling in confined spaces

2200 Series

Key Specifications:

- Width range: 1.75" (44 mm) to 24" (610 mm)

- Length range: 1.5' (457 mm) to 24' (7,315 mm)

- Load capacity: Up to 120 lbs (54 kg)

- Maximum speed: 400 ft/min (122 m/min)

Ideal Applications:

- Food packaging and processing

- Light assembly operations

- Automated inspection systems

- Product transfers between processes

- Accumulation and buffering

2700 Series Medium Duty

Key Specifications:

- Width range: 8" to 36" (203 mm to 914 mm)

- Length range: 20" to 24' (508 mm to 7,315 mm)

- Load capacity: Up to 150 lbs (68 kg)

- Maximum speed: 400 ft/min (122 m/min)

Ideal Applications:

- E-commerce order fulfillment

- Automotive parts handling

- Packaging line product transfers

- Machine integration in manufacturing

- Robotic pick-and-place operations

3200 Series

Key Specifications:

- Width range: Up to 48" (1,219 mm)*

- Length range: 30" to 99' (1,219 mm to 30,175 mm)**

- Load capacity: Up to 1,000 lbs (455 kg)

- Maximum speed: 600 ft/min (182 m/min)

Ideal Applications:

- Heavy parts handling in automotive manufacturing

- Bulk product conveying in distribution centers

- Metal stamping and fabrication processes

- Large-scale automated assembly lines

- High-speed packaging operations

DCMove

Key features:

- Economical painted steel frame construction

- Widths from 12" (305 mm) to 60" (1,524 mm)

- Lengths up to 98' (30 m)

- Load capacity up to 75 lbs/ft (111 kg/m)

- Internally mounted motor for reduced footprint

Ideal Applications:

- E-commerce order sortation

- Parcel handling in distribution centers

- Cross-docking operations

- General material transport in warehouses

- Packaging line product movement

Features & Benefits of Dorner Belt Conveyors

Smooth Elevation Solutions

Modular Belt Material Options:

- Acetal: Excellent wear resistance and low friction

- Nylon: High strength and impact resistance

- Polyethylene: FDA-compliant for packaged food handling applications

- Polypropylene: Chemical resistance for harsh environments

Fabric Belt Material Options:

- Nylon: Durable and abrasion-resistant

- Polyester: High strength-to-weight ratio

- PVC: Economical and versatile

- Silicone: High-temperature resistance

- Thermoplastic urethane: Excellent wear and chemical resistance

Surface Types

Modular Belt Surface Types:

- Flat top: Smooth surface for general conveying

- Flush grid: Allows for air flow and drainage

- Raised rib: Provides product separation and reduced contact area

Fabric Belt Surface Types:

- Smooth: Ideal for general conveying and accumulation

- Textured: Enhances grip for incline applications

- Cleated: Secures products during elevation changes

- Perforated: Allows for air flow in cooling or drying applications

Application examples:

- Flat top surfaces for packaging lines

- Flush grid designs for food processing with wash-down requirements

- High friction belts for automotive parts handling

- Cleated belts for inclined conveying in distribution centers

Integration Capabilities

- Low-profile frames fit easily inside or through machinery

- Compatible with a wide range of accessories:

- Guide rails for product containment

- Sensors for automated control

- Motors and controls for precise speed regulation

- Modular designs allow for easy reconfiguration as your needs change

Customization Possibilities

- Widths, lengths, and configurations tailored to your exact needs

- Custom coatings for enhanced durability or specialized applications

- Color-matching available to align with your brand or safety standards

- Extensive range of accessories for enhanced functionality

Uptime-Enhancing Features

- Belt life indicators for proactive maintenance scheduling

- V-guided belting ensures consistent tracking and reduces misalignment

- Precision rack-and-pinion belt tensioning for optimal performance

- Proprietary bearings engineered for extended life and reduced maintenance

Space-Saving Designs

- Low-profile options ideal for integration into tight spaces

- Flexible configurations to optimize layout efficiency

- Modular designs allow for easy expansion or reconfiguration

Applications & Industries Served

- Automation: Precision positioning for robotic pick-and-place operations

- Consumer Packaged Goods: Efficient handling of diverse product sizes and shapes

- Food Processing: Sanitary conveying solutions for safe and efficient food product handling

- Packaging: Seamless integration with packaging machinery for optimal throughput

- E-Commerce: High-speed sorting and distribution for order fulfillment

- Integrators: Flexible solutions for custom production line designs

- Material Handling & Industrial: Robust conveying for heavy-duty applications

- Medical: Clean room-compatible designs for sterile manufacturing environments

Why Choose Dorner?

- Industry-leading 10-year warranty for peace of mind

- Fastest lead times in the industry: Most conveyors ship in 5 days or less

- Experienced service technicians provide lifetime support for your conveyor systems

- Global presence ensures local support and quick response times

Ready to Optimize Your Production?

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy