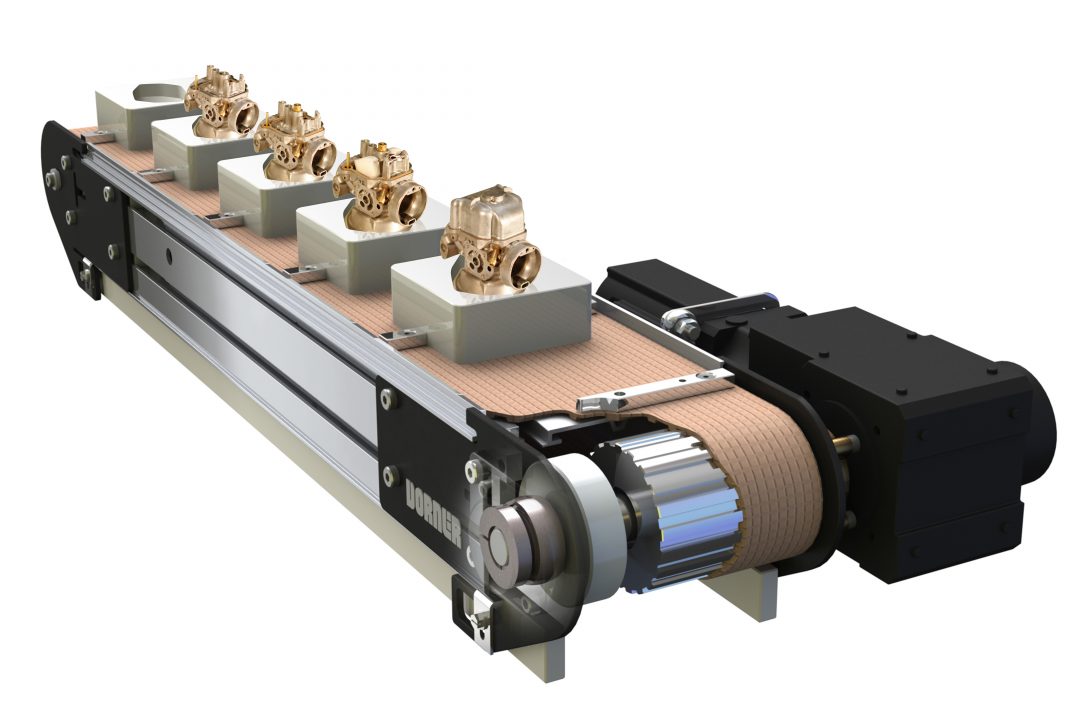

3200 Precision Move Conveyors

Contact Us

Conveyor specialists are ready to help you find the right solution

Benefits of 3200 Series Precision Move Conveyors:

Specifications:

- Loads up to 750 lbs (340 kg)

- Belt speeds up to 517 ft/min (158 m/min)

- Belt widths: 4” (95 mm) to 18” (457 mm) in 2” increments

- Conveyor lengths: 2’ (610 mm) to 50’ (15,240 mm)

- 21 tooth H (1/2”) pitch profile timing belt (10 mm Metric pitch available)

- 3.3” (84 mm) pitch diameter drive and idler pulleys turn approximately 10.5” (267 mm) of belt per revolution

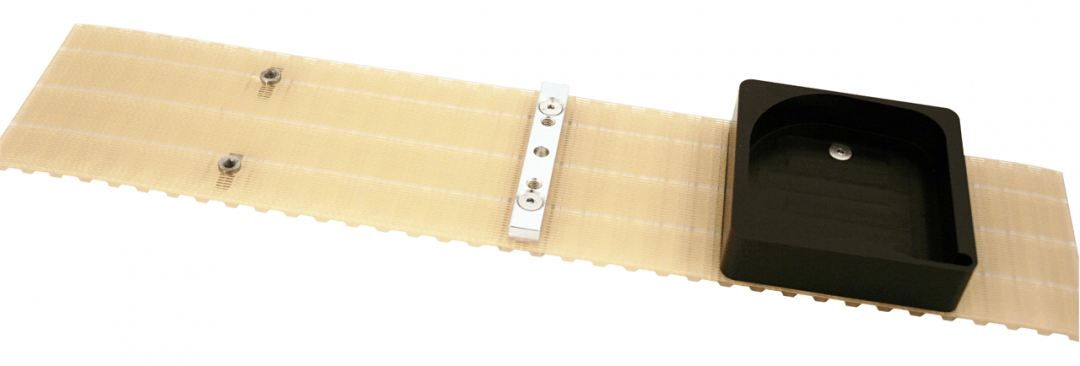

- Optional M5 belt inserts

- Optional pallet mounting bars, 5/16” x 1/2” plated steel

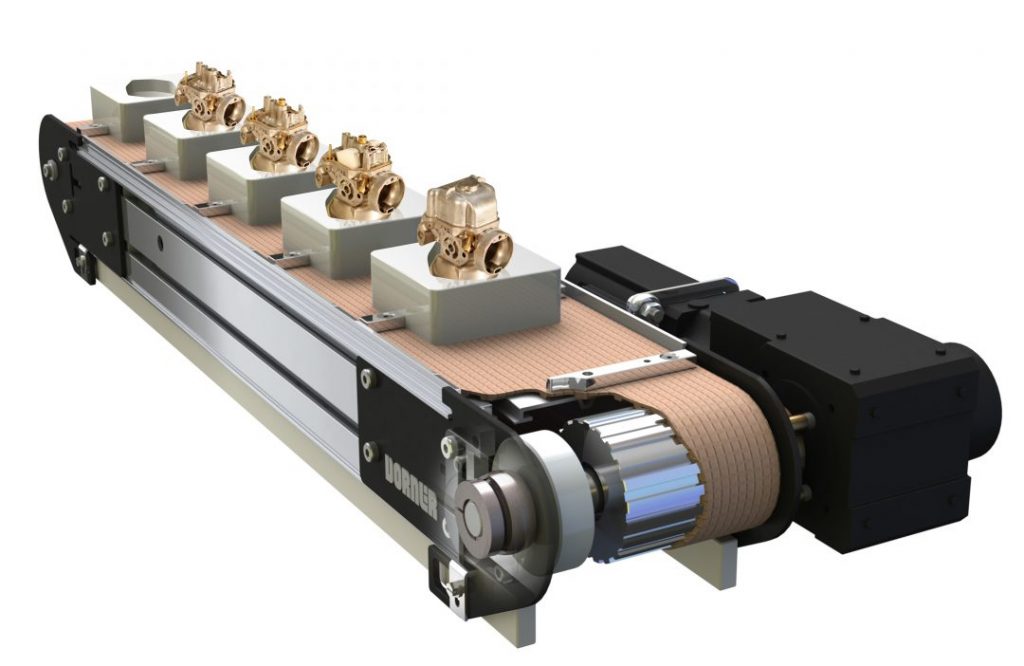

- Conveyor package w/ servo motor index repeatability ± 0.02”

- 100 Indexes per minute rated

Features & Benefits:

- High load capacity urethane belting with kevlar cords (True Timing Belt)

- No capacity drop when pushing belt

- All widths feature a single belt for increased mounting flexibility

- Positive drive no slip belting and side guides provide worry free belt tracking

- Use optional cleats to create pockets for controlled part flow

- Minimum pallet mounting bar is spacing 1” in length

- T-slots make mounting accessories simple with no drilling or special tools

- Compatible with standard drive packages

- Available with servo motor and mounts for increased accuracy of index

- Servo package includes fully integrated solution with intuitive PC interface

- Sealed ball bearings

- Accessories

- Belting

- Profiles & Guiding

- Support Stands & Accessories

- Gearmotors

- Mounting Packages

- Manuals & Literature

Accessories

Belting

Profiles & Guiding

Support Stands & Accessories

Gearmotors

Mounting Packages

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| 3200 Series Engineering Manual | 108 | 11.68 MB |

| Literature | Pages | File Size |

| 3200 Series Brochure | 2 | 1.72 MB |

| Flexible Packaging Brochure | 5 | 3 MB |