- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Dorner Conveyor Parts

Ready When You Need Them

NEW: DTools Spare Parts Portal

Use our new Spare Parts Portal to search for the replacement parts associated with your order. Review parts details, pricing, lead times, and service manuals by clicking the Go to Portal button below.

Or click here to fill out a replacement parts request form, and a service team member will gladly assist you.

Don’t Let Low Spare Parts Inventory Keep Your Production Line Down

Every minute of downtime can cost thousands. You know the pressure of keeping production lines running smoothly. That’s why Dorner maintains an extensive inventory of ready-to-ship Dorner conveyor parts to minimize downtime and maximize your productivity and profit.

Keep Your Lines Moving with Dorner Conveyor Parts

Why Choose Dorner for Your Conveyor Parts?

- Extensive in-stock inventory

- Fast and reliable shipping

- Genuine OEM parts

- Expert technical support

- Comprehensive warranty coverage

Fast Access to Critical Spare Parts

- Replacement conveyor belts

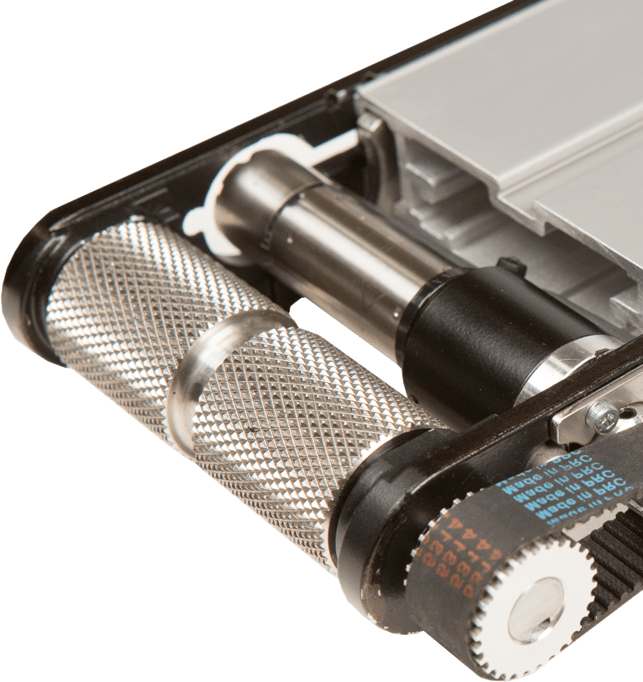

- Drive components

- Motors and controllers

- Bearings and spindles

- Wear components

Understanding Conveyor System Parts

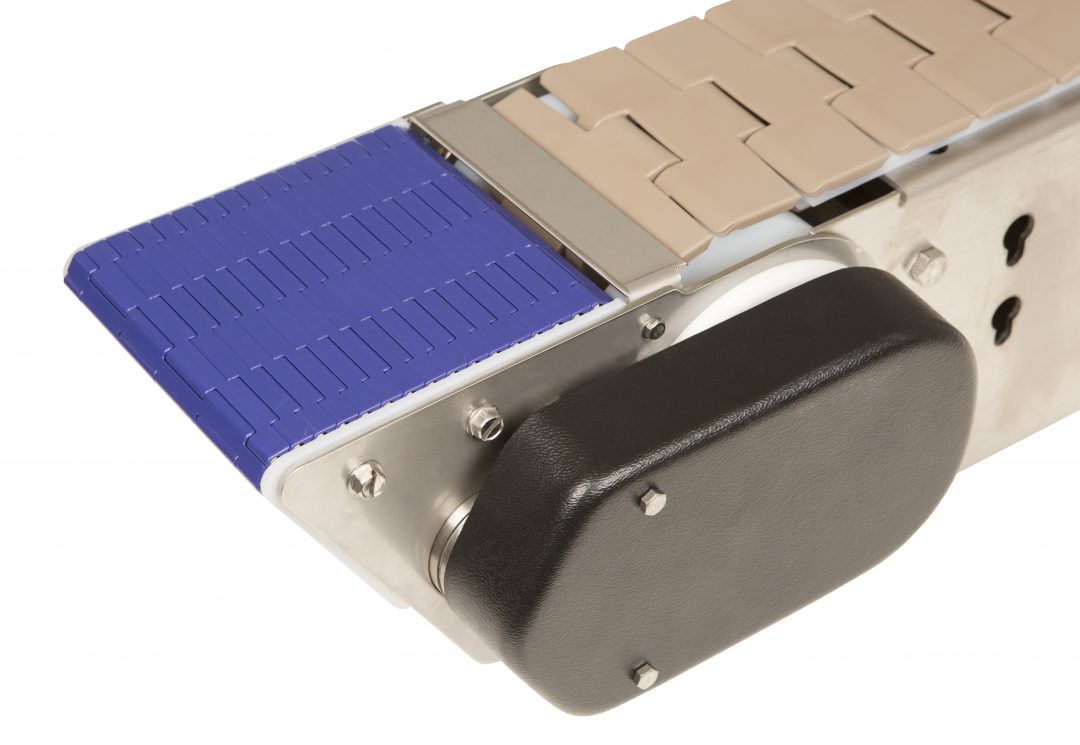

Conveyor Belts: The Heart of Your System

Our belt solutions include:

- Fabric and modular conveyor belts

- Flexible chains

- Custom materials and configurations

Pro Tip: For longevity, keep the spare belt at room temperature and away from UV lighting. Modular belts and flexible chains can be purchased by the box. Additionally, Dorner offers tools for removing pins for fast and simple replacement of individual links.

Critical Replacement Parts

Essential Components:

- Spindles and tail plates

- Precision bearings

- Motors and controllers

- Pulley kits and timing belts

- Wear strips and sprockets

System Components:

- Frames and bedplates

- Support stands

- Guide rails and accessories

- Mounting hardware

Strategic Parts Management

Pre-Configured Parts Kits

Level 1 Maintenance Kit includes:

- Complete belt assembly

- Drive tail kit

- Installation documentation

Level 2 Comprehensive Kit includes:

- Complete belt assembly

- Drive tail kit

- Idler tail kit

- Full maintenance manual

Complete Conveyor Parts Support Programs

Preventive Maintenance Program

- Comprehensive system inspections

- Professional parts replacement

- Performance optimization

- Preventive maintenance planning

Free Parts Auditing Service

- Expert system evaluation

- Critical spares identification

- Custom stocking recommendations

- Priority shipping setup

Recommended Spare Parts Inventory

Essential Spares Package

- Replacement belts

- Drive components

- Critical wear items

- Emergency repair parts

Parts Ordering Made Simple

- Find your model number

- View available parts

- Place your order

- Same-day shipping*

Expert Support When You Need It

- 24/7 emergency parts support

- Factory-trained technicians

- Comprehensive technical documentation

- Installation assistance

The Dorner Difference

We’re committed to being the last conveyor company you’ll ever need:

- Inventory of current and legacy Dorner Conveyor parts

- Rapid shipping

- Expert technical support

- Complete service solutions

Conveyor Parts: A Comprehensive Guide

Introduction to Conveyor Parts

Conveyor belts are the heart of a conveyor system. These conveyor parts come in multiple types, each designed for specific applications:

- Belt Material Options

Dorner offers modular, cleated, flat, and magnetic belts to handle diverse products and environments. From sanitary belts ideal for food handling to heavy-duty belts for industrial use, each material has unique benefits.

- Belt Tensioning and Tracking Mechanisms

Properly tensioned and tracked belts reduce wear and improve efficiency. Dorner’s conveyor parts include advanced tensioning systems that help keep belts aligned.

- Applications by Industry

Whether in pharmaceuticals, electronics, or automotive, choosing the right belt can optimize productivity. For example, cleated belts prevent slippage in inclined conveyors, while magnetic belts secure metal parts.

A conveyor’s frame is its backbone, supporting all other conveyor parts and maintaining structural integrity.

- Frames and Supports

Dorner’s frames, crafted from materials like stainless steel and aluminum, are durable and corrosion-resistant, making them suitable for both standard and sanitary environments.

- Rails and Guide Components

Guide rails, sliders, and fencing are critical for keeping products aligned. Dorner’s configurable parts can be adjusted to accommodate a variety of product sizes.

- Mounting Brackets and Clamps

These conveyor parts help secure frames to the floor, walls, or other equipment, offering stability and adaptability for different conveyor configurations.

Drive and motor components power conveyor systems, keeping materials moving efficiently.

- Conveyor Motors and Gearboxes

Dorner provides AC, DC, and servo motors designed for energy efficiency and precise control.

- Motorized Pulleys

These self-contained conveyor parts integrate the motor within the pulley, reducing footprint and maintenance requirements.

- Variable Speed Controllers

With variable speed options, Dorner’s conveyor motors adapt to changing production needs, enhancing flexibility and control over conveyor speed.

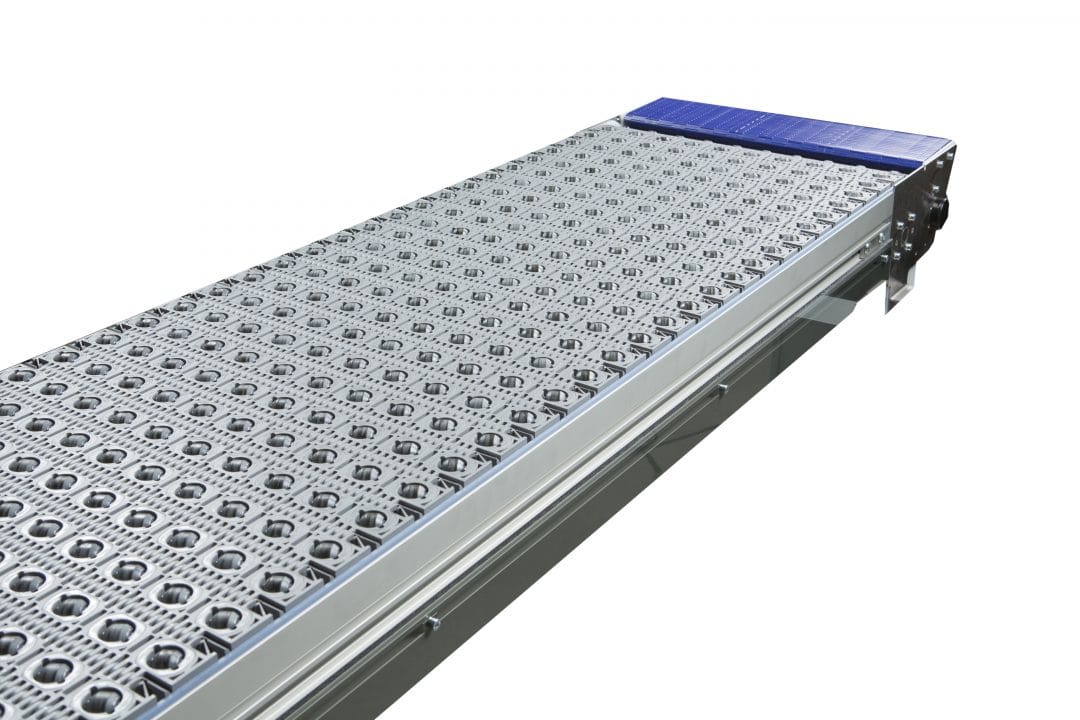

Rollers and idlers are the unsung heroes of smooth, reliable conveyor operation.

- Drive Rollers and Return Rollers

These conveyor parts support the belt, minimizing friction and ensuring smooth, continuous movement.

- Impact and Carrying Idlers

Designed to withstand heavy loads, these rollers absorb shock, protecting belts and improving durability.

- Types of Roller Materials

Dorner offers rollers in rubber-coated, stainless steel, and other materials, each suited to different conditions such as high temperatures or corrosive environments.

Pulleys and bearings are essential conveyor parts for belt alignment, tension, and smooth rotation.

- Head and Tail Pulleys

These pulleys guide and drive the belt, ensuring even movement and precise positioning of materials.

- Snub Pulleys and Take-up Pulleys

These conveyor parts help control belt tension and redirect the belt where necessary, especially useful in complex systems.

- Bearing Types for Conveyors

Sealed and open bearings reduce friction and support rotation, ensuring long-lasting, smooth operation of all moving parts.

Accessories enhance conveyor capabilities, adapting them to specific needs.

- Cleats and Flights

Cleats create partitions on the belt, allowing inclined transport of loose or fragile items, ideal for food or parts assembly applications.

- Conveyor Guards and Covers

Safety is critical in conveyor systems, and guards and covers prevent accidental contact with moving parts, protecting both personnel and equipment.

- Transfer Plates and Chutes

These conveyor parts aid in the smooth transfer of materials between belts or other equipment, reducing product handling time.

Modern conveyors often integrate automation for increased productivity.

- Sensors and Detection Devices

Optical and proximity sensors track product location and volume, facilitating sorting and automated workflows.

- Programmable Logic Controllers (PLCs)

PLCs are essential conveyor parts for automating conveyor speeds, directions, and sorting, allowing integration into larger systems.

- Emergency Stop and Safety Controls

Dorner’s emergency stop controls ensure quick shutdown in case of a safety hazard, essential for any high-speed or high-load conveyor system.

Maintaining your conveyor system is key to extending its lifespan and ensuring efficiency.

- Lubrication Systems and Grease Fittings

Proper lubrication reduces wear, extending the lifespan of rollers, bearings, and belts.

- Replacement Parts and Kits

Dorner’s maintenance kits include belts, pulleys, and other common replacement parts, minimizing downtime and simplifying maintenance.

- Cleaning and Inspection Parts

Tools designed for easy access and effective cleaning help keep conveyor parts in optimal condition, reducing build-up and contamination.

Selecting the right parts involves assessing several factors.

- Factors to Consider

Load type, environmental conditions, speed, and industry regulations are key considerations.

- Customizing for Application Needs

Dorner’s modular conveyor parts can be customized to meet unique requirements, from food-grade components to heavy-duty parts for industrial settings.

- Cost vs. Performance Trade-offs

Investing in high-quality parts can reduce long-term costs by minimizing repairs and replacement needs.

When sourcing conveyor parts, it’s essential to work with trusted suppliers who can meet your operational demands.

- Trusted Conveyor Part Suppliers

Dorner is recognized for delivering high-quality, durable conveyor parts that support a wide range of industries.

- Ordering and Lead Times

Plan maintenance around part availability, considering lead times to avoid unexpected downtime.

- Installation and Support Services

Choosing suppliers like Dorner, who offer expert installation and ongoing support, ensures your conveyor parts are optimized for performance and reliability.

Conclusion

Request Replacement Parts

Please fill out the form below to request replacement parts for your conveyor system, and one of our team members will be in contact to help you place your order.

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy