- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Canning & Bottling Conveyor Solutions

Canning & Bottling Conveyor Solutions from Dorner Conveyors

Benefits of Dorner's Conveyor Solutions for Canning & Bottling

Hygienic Design for Product Safety and Compliance ✓

Gentle Handling to Minimize Product Damage ✓

Increased Throughput and Productivity ✓

Minimal Maintenance and Reduced Downtime ✓

Customizable Options to Meet Specific Needs ✓

Key Applications in Canning & Bottling

Container Handling and Orientation

Filling and Sealing

Labeling and Coding

Packaging and Case Packing

Integration with Inspection and Quality Control Systems

Dorner's Conveyor Systems for Canning & Bottling

AquaGard GT Series

AquaPruf Ultimate Series

2200 Low Profile Conveyors

3200 Heavy Duty Conveyors

FlexMove Stainless Steel Conveyors

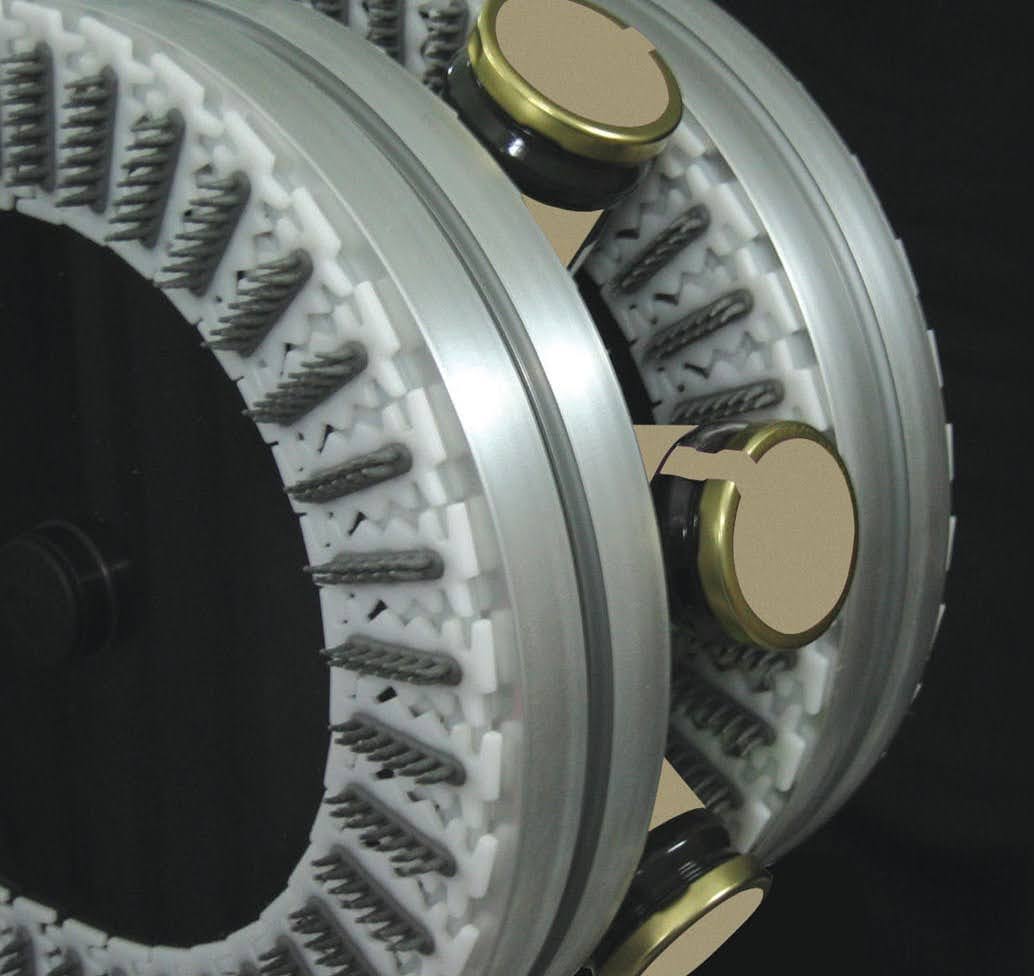

Garvey Accumulation Systems

Dorner is proud to partner with Garvey to offer top-of-the-line Accumulation Systems that can help you maximize your throughput and provide efficient buffering and product flow control between packaging equipment. These systems help maintain consistent line speeds, reduce downtime, and improve overall efficiency.

Automation Solutions in Canning & Bottling

Our conveyors are designed to integrate effortlessly with a wide range of automation equipment, such as:

- Fillers: Dorner's conveyors provide precise, stable product transfer to keep filling machines operating at peak efficiency. We can customize our systems to match the specific requirements of your fillers, ensuring optimal synchronization and throughput.

- Cappers: Accurate capping is essential for product freshness, safety, and shelf life. Dorner's conveyors offer consistent positioning and timing to ensure caps are applied correctly every time, minimizing defects and waste.

- Labelers: Whether you're using pressure-sensitive, glue-applied, or shrink sleeve labels, Dorner's conveyors provide the stability and precision needed for high-quality labeling. Our systems can accommodate a variety of labeling equipment and configurations to meet your specific needs.

- Case Packers: Efficient case packing is critical for timely distribution and product protection. Dorner's conveyors seamlessly integrate with case packing and palletizing equipment, providing reliable product collation and positioning for optimal throughput and accuracy.

- Increase efficiency and productivity

- Reduce labor costs and minimize human error

- Improve product quality and consistency

- Enhance traceability and data collection

- Optimize floor space utilization

Sanitary Conveyors With Hygienic Design

Stainless steel construction

Open frame designs

Ease of cleaning and maintenance

FDA-approved materials

Custom Solutions for Canning & Bottling

Some examples of custom solutions we can provide for canning and bottling include:

- Specialized belting: Dorner offers a wide range of belting options to suit different product characteristics and processing requirements. From non-slip surfaces for improved grip to Positive ThermoDrive belts for enhanced sanitation, we can customize your belting to ensure optimal performance and product quality.

- Product-specific handlin: Whether you're processing delicate glass bottles, lightweight aluminum cans, or any other type of container, Dorner can design a conveyor system that provides gentle, precise handling to minimize damage and maintain product integrity.

- Integration with specialized equipment: If your canning or bottling operation involves unique or proprietary equipment, Dorner can develop custom interfaces and integration solutions to ensure seamless, efficient product transfer between your conveyors and other machinery.

- Optimized layouts: Space is often at a premium in production facilities. Dorner can create custom conveyor layouts that maximize space utilization, improve product flow, and minimize bottlenecks. From multi-level systems to tight-radius turns, we'll design a solution that fits your facility and enhances your overall efficiency.

Case Study: The Suter Company Streamlines Deviled Egg Production with Dorner

The results were impressive:

- Processing time dropped from 60 minutes to just 8 minutes per case – a savings of nearly 20%

- Consistent packaging rates of deviled eggs every 10 seconds at the end of the line

- Improved cleanliness with integrated cleaning jets and the 7400 Series' sanitary design features

Industries that Benefit from Dorner's Canning & Bottling Conveyor Solutions

- Food and Beverage: Dorner’s hygienic conveyors are ideal for processing and packaging canned fruits, vegetables, soups, sauces, and beverages, ensuring food safety and regulatory compliance.

- Craft Brewing and Distilling. Dorner’s conveyors provide gentle handling, precise positioning, and seamless integration with filling, capping, and labeling equipment, making them perfect for the growing craft brewing and distilling industry.

- Pharmaceutical and Nutraceutical: The AquaPruf 7400 Ultimate Series, with its USDA certification and advanced sanitary features, is particularly beneficial for handling canned or bottled vitamin supplements, energy drinks, and health tonics.

- Personal Care and Household Products: Companies producing aerosol cans for shaving cream, deodorants, and cleaning products can benefit from Dorner’s precise product handling and efficient integration with packaging equipment.

- Contract Packaging: Dorner’s flexible, modular conveyor designs allow third-party contract packaging companies to easily reconfigure and adapt to changing production needs for various canned and bottled products.

- Pet Food and Treat: Dorner’s sanitary conveyors are well-suited for handling canned and pouched pet food and treats, ensuring the highest standards of quality and safety.

Services and Support

Installation Services

Training Services

Exceptional Aftermarket Support

Canning & Bottling Conveyors from Dorner

Contact Us

Frequently Asked Questions

How do Dorner's conveyors handle the wet conditions in canning and bottling facilities?

Can Dorner's conveyors accommodate the high speeds required in canning and bottling production lines?

How do Dorner's conveyors ensure gentle handling of delicate containers like glass bottles?

How can Dorner's conveyors help improve product quality and consistency in canning and bottling operations?

How does Dorner ensure their conveyors comply with food safety regulations in the canning and bottling industry?

At Dorner, food safety is a top priority. Our conveyors are designed and manufactured to meet or exceed the strictest food safety regulations and standards, including those set by the FDA, USDA, and 3-A. Some key features that ensure compliance include:

- Use of FDA-approved materials, including stainless steel, food-grade plastics, and specially formulated belting

- Hygienic design principles, such as open frame construction, sloped surfaces, and minimized crevices to prevent debris accumulation

- Easy-to-clean features, like removable belts, tool-less disassembly, and accessible components for thorough sanitation

- Compliance with industry-specific standards, such as 3-A Sanitary Standards for dairy processing equipment (when applicable)

We can also provide documentation and support to help you validate your conveyor system’s compliance with relevant regulations and standards, giving you peace of mind and confidence in your production processes.

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy