In modern manufacturing facilities, space is premium, and every piece of equipment must work in sync with other machinery and… Read more »

Category: Engineered Solutions

New Conveyor Projects in the Shop

The new year has brought many new projects into the shop at Dorner’s Hartland facility, and our Engineered to Order… Read more »

4 Factors to Consider When Choosing a New Conveyor

Many factors can go into choosing a conveyance system that meets both industry requirements and your company’s unique needs. That’s… Read more »

Optimize Space with Conveyor Elevations and Line Egress Solutions

Why Systems Need to Be Flexible Modern manufacturing requires facilities to maximize efficiency and ensure product quality. However, space… Read more »

Easy 90 Degree Transfers

Controlling product flow doesn’t have to be complicated. With 90 degree transfers it can be as easy as moving off… Read more »

Save Time and Money with Dorner’s Engineered Solutions

Do you have an application that calls for an extra-long conveyor, but an existing obstruction is hindering the installation of… Read more »

Elevator Provides Additional Product Storage for Accumulation System

See the system in action at the end of the post! When downstream equipment is non-operational, an accumulation system can… Read more »

Retractable Tail Provides Simple Walk-Through Access

Space can be limited on the factory floor and equipment isn’t always easy to access. Conveyors and other machinery… Read more »

Create Safe and Fast Walk-Through with Lift Gates

Lift gate conveyors are a popular solution for creating safe and fast walk-through access to maximize usable space. Take… Read more »

Can Dorner Design A Solution For Your Application?

Dorner’s Engineered Solutions Group (ESG) can create a custom conveyor or conveyor system for almost any customer need. Dorner has… Read more »

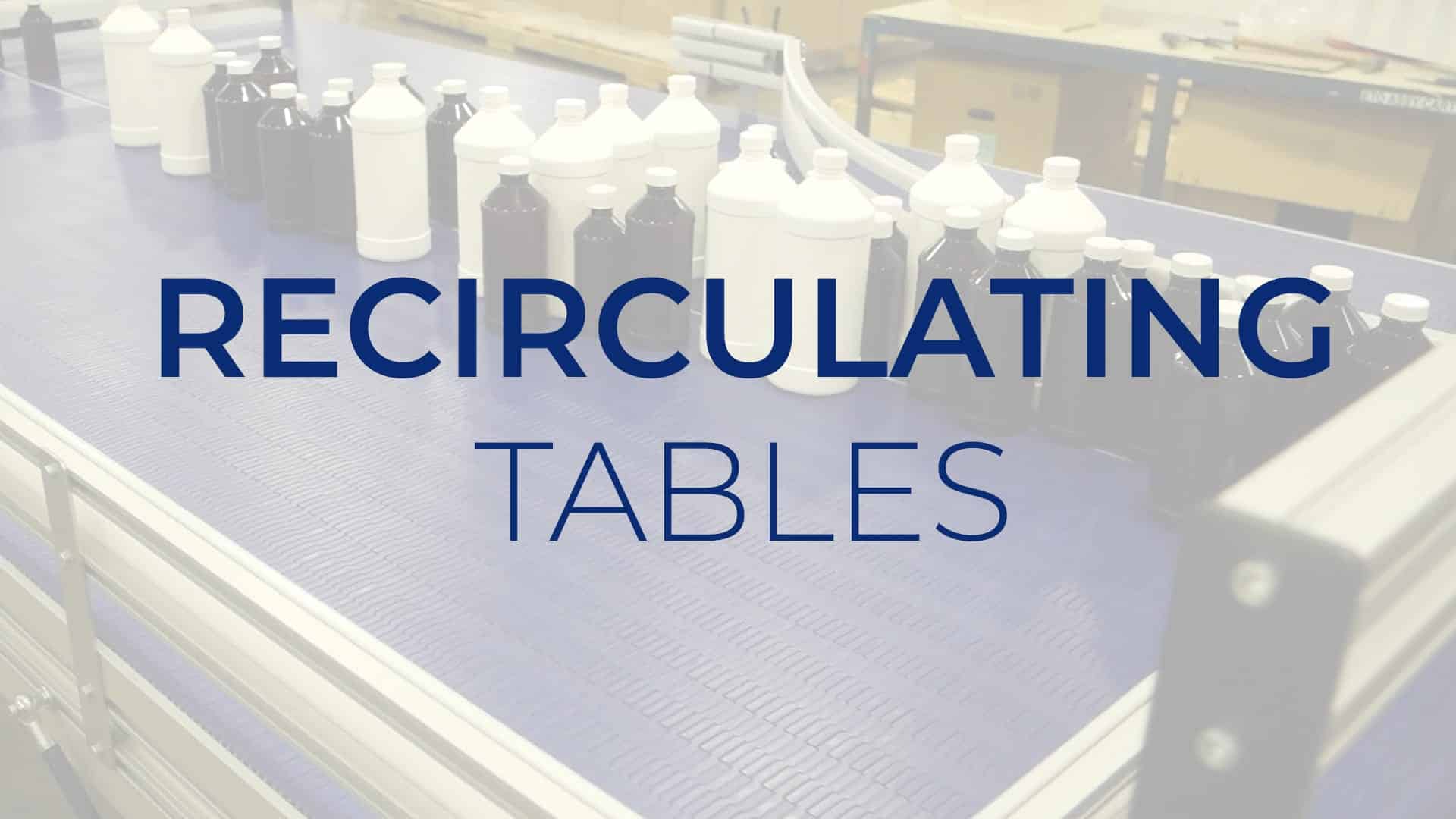

5 Important Facts About Dorner’s Recirculating Tables

See our recirculating tables in action at the end of the post! 1. They enable product lines to keep pace… Read more »

Add Simple Automation with Retractable Conveyors

A retractable conveyor, or retracting tail, is a conveyor frame with the ability to retract or extend, typically on… Read more »

How do Diverting and Sorting Conveyors Work? Take a Look.

Conveyor diverters and sorting conveyors work by handling product based on such characteristics as weight and shape along with line… Read more »

A Simple and Sanitary Diverting Solution to Increase Product Flow

Diverters, pushers and gates are used when controlling the continuous flow of products through the line is critical to… Read more »

Dorner Merge Conveyors

Dorner offers a variety of solutions for merging products in a processing line. We can merge 2, 3, 4 or… Read more »

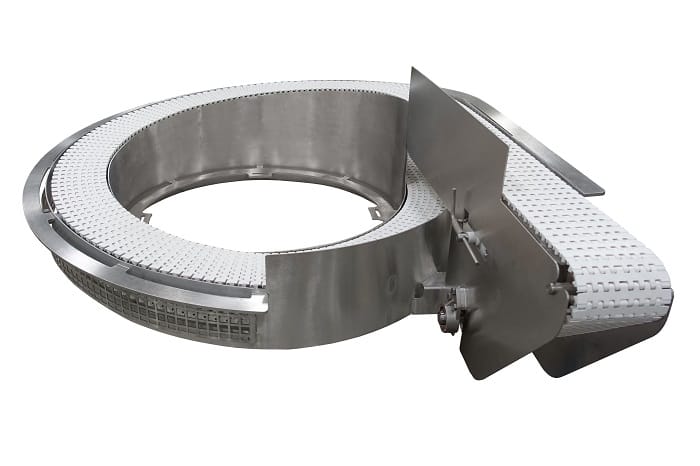

Sanitary Helix Now with Added Features

As we’ve highlighted in the past, Dorner has created Sanitary Helix designs to integrate with Hoosier Feeder’s Food Grade Centrifugal… Read more »

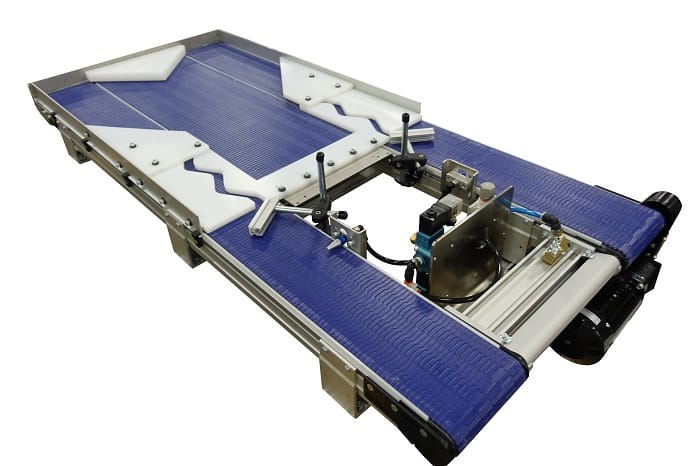

Custom Accumulation Systems

When you need to ensure a steady supply of product to a machine or to hold a supply of product… Read more »

Magnetic Conveyors Customized for Efficiency

Every business needing a magnetic conveyor in its facility has a specific product to run. Therefore, no two solutions… Read more »

Dorner’s Engineered Solutions Group Injects Automation and Ingenuity into Conveyor Systems for Complex Applications

When a customer needed to upgrade their existing food processing line to merge two lanes of frozen pizzas into… Read more »

Case Handling System using 3200 Series Conveyors with Intralox ARB Technology

In a recent application, a customer needed a flexible system that could handle many different sizes and patterns of… Read more »

Custom Frozen Pizza System

At Dorner, we can provide anything from a single conveyor to a full system. Recently, Dorner worked with a… Read more »

Increase Throughput and Efficiency with a Tote Handling System

See this system in action at the end of the post! Recently, a pharmaceutical company came to Dorner looking for… Read more »

Dorner SmartFlex Pallet Systems now available in D-Tools

Dorner’s SmartFlex® Pallet System conveyors are now available in D-Tools, Dorner’s online conveyor configurator that includes 2D and 3D CAD libraries and other… Read more »

Powered Side Guide Highlighted on Dorner’s SmartFlex Conveyor with FlexMove Technology

Dorner recently worked with a customer who needed to convey small plastic bottles. The solution required a number of different… Read more »