Welcome to Dorner!

Your expert in innovative conveyor technology!

Dive into the world of powerful and customized conveyor technology. Discover how our solutions enhance the efficiency of your production processes.

Dorner: Our Tradition is Innovation

Founded in 1966 in Hartland, Wisconsin, we have become a global leader in the development and manufacturing of innovative conveyor systems. Our success story is built on our dedication to delivering high-quality precision products while providing responsive customer service. We break with conventional thinking and find creative solutions to our customers’ challenges.

Versatile

Our flexible modular system guarantees solutions tailored exactly to your requirements.

Fast

From product delivery to support, we prioritize a fast turnaround, quality and efficiency.

Expertise

Our 55+ years of experience guarantee optimal solutions for your needs.

Durable

High-quality materials and modern manufacturing ensure high durability and resilience.

Innovative

We break with conventional thinking and find creative solutions for your requirements.

Support

Our team offers a wide range of services to ensure your system runs smoothly throughout its lifespan.

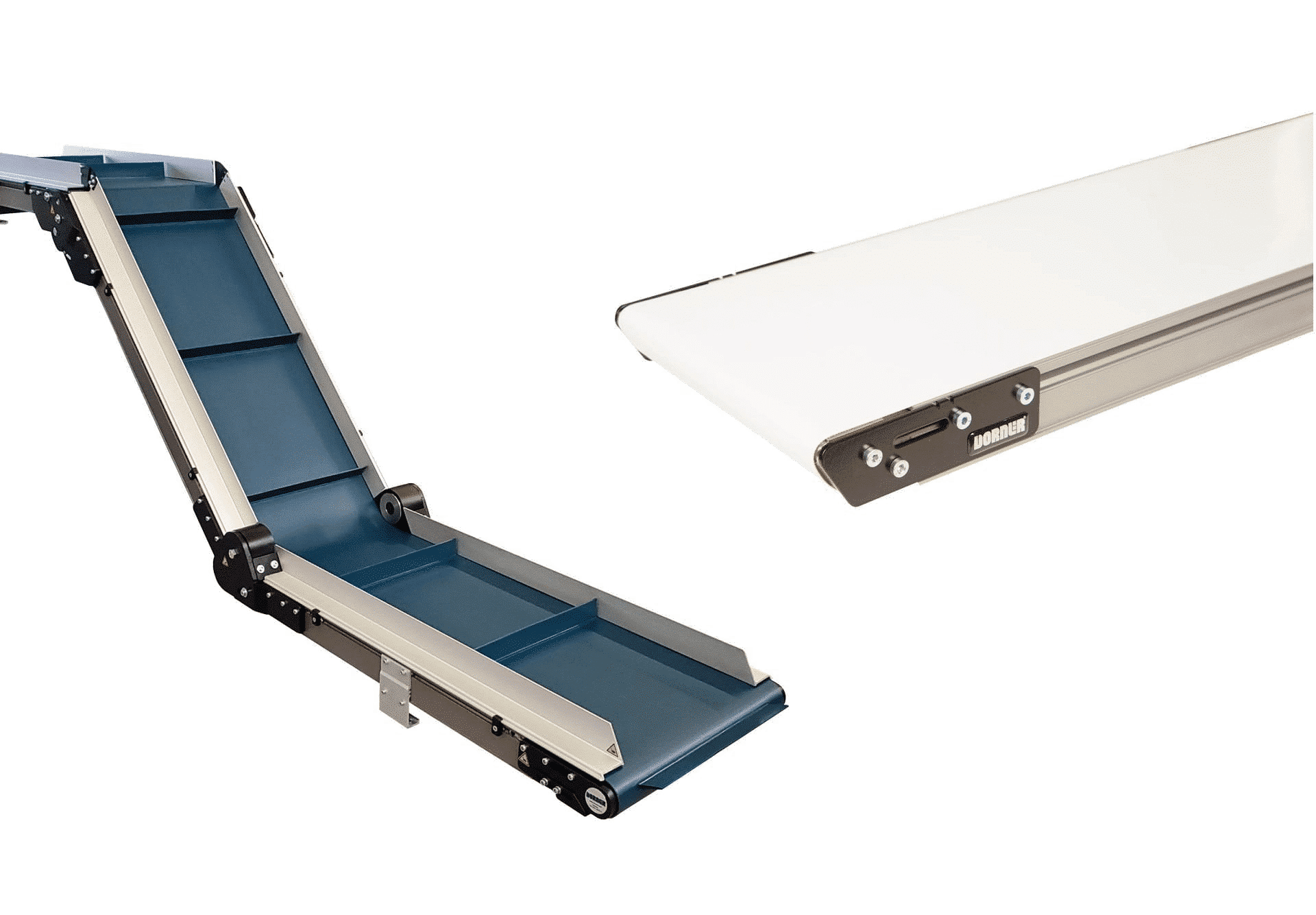

Industrial

Conveyors

Improve efficiency and boost accuracy with Dorner’s industrial and automation conveyors. Our conveyors allow you to move product at a precise time to an exact location, ensuring that everything is always in the correct phase of the production line.

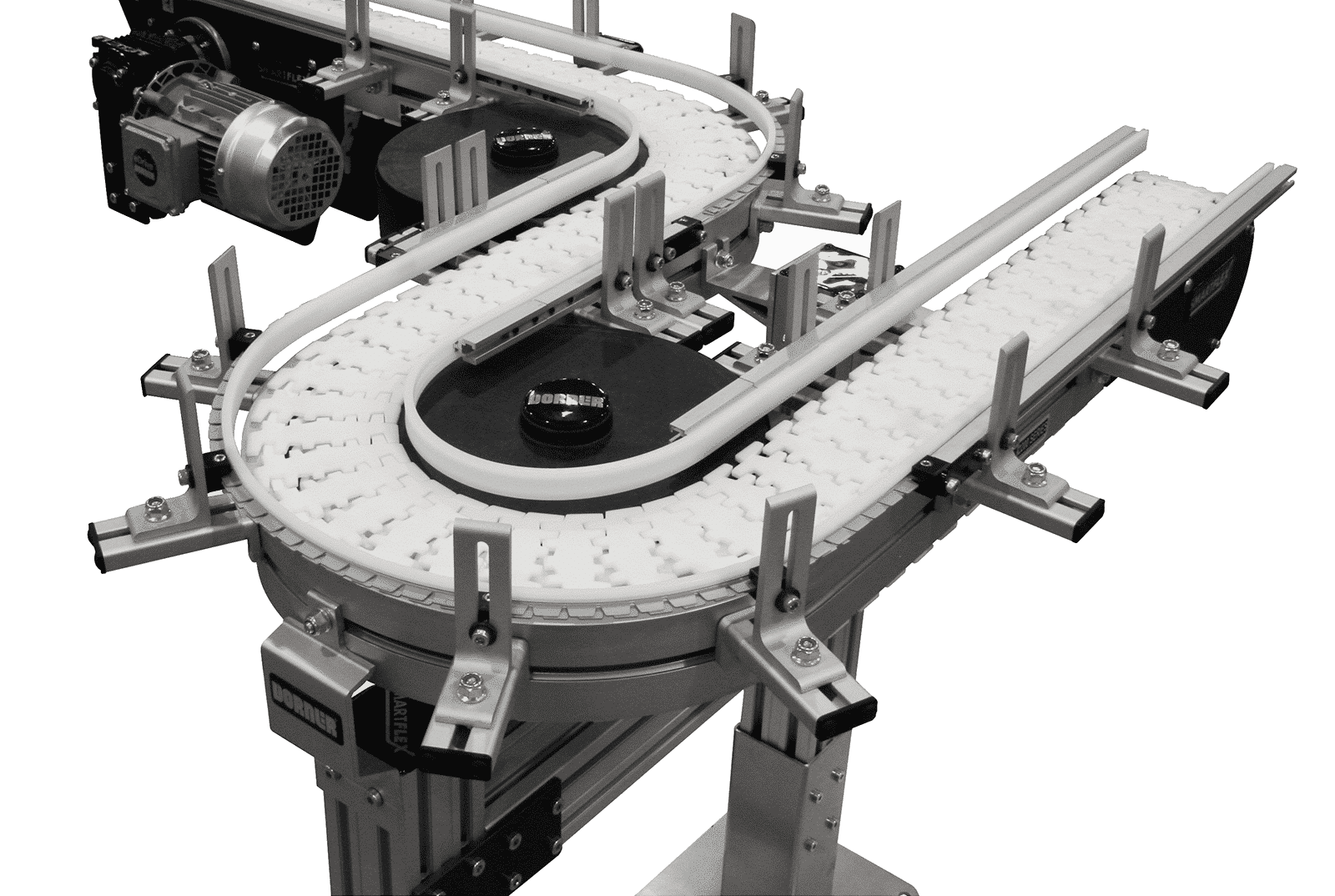

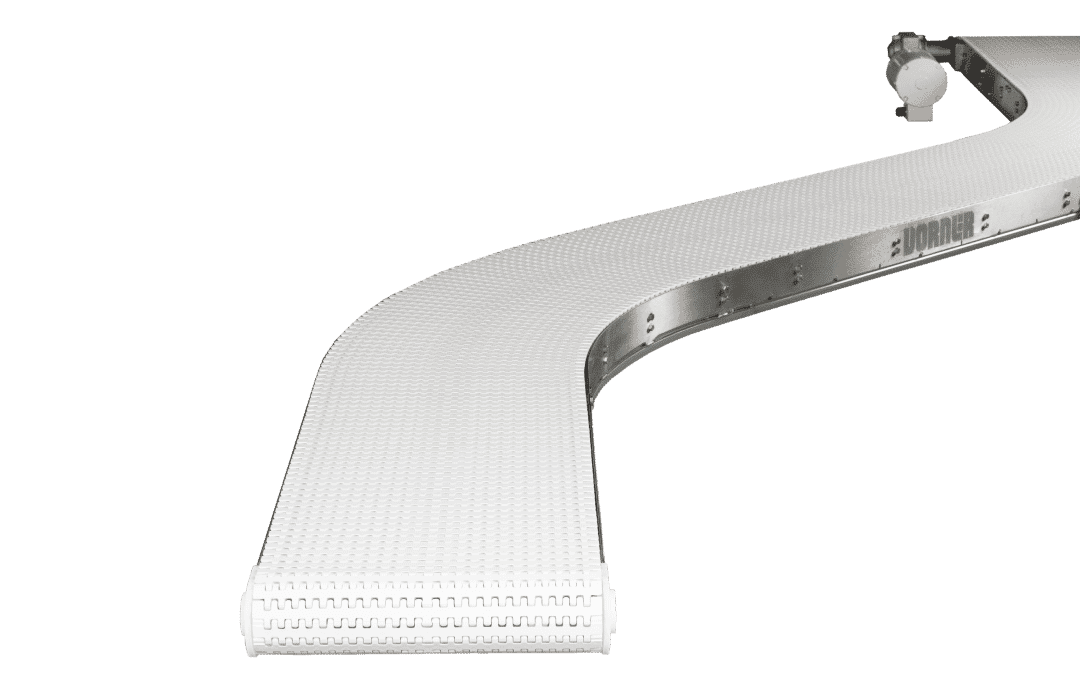

Flexible Chain

Conveyors

Flexible chain conveyors easily adapt and expand to changing requirements. Our FlexMove line is equipped to accommodate virtually any material handling application and provide efficient solutions for a wide range of manufacturing industries.

Stainless Steel

Conveyors

Conveyors designed specifically for the food industry, easy to clean, and designed for maximum food safety. Dorner’s sanitary conveyors are engineered to promote hygienic design while meeting the highest standards.

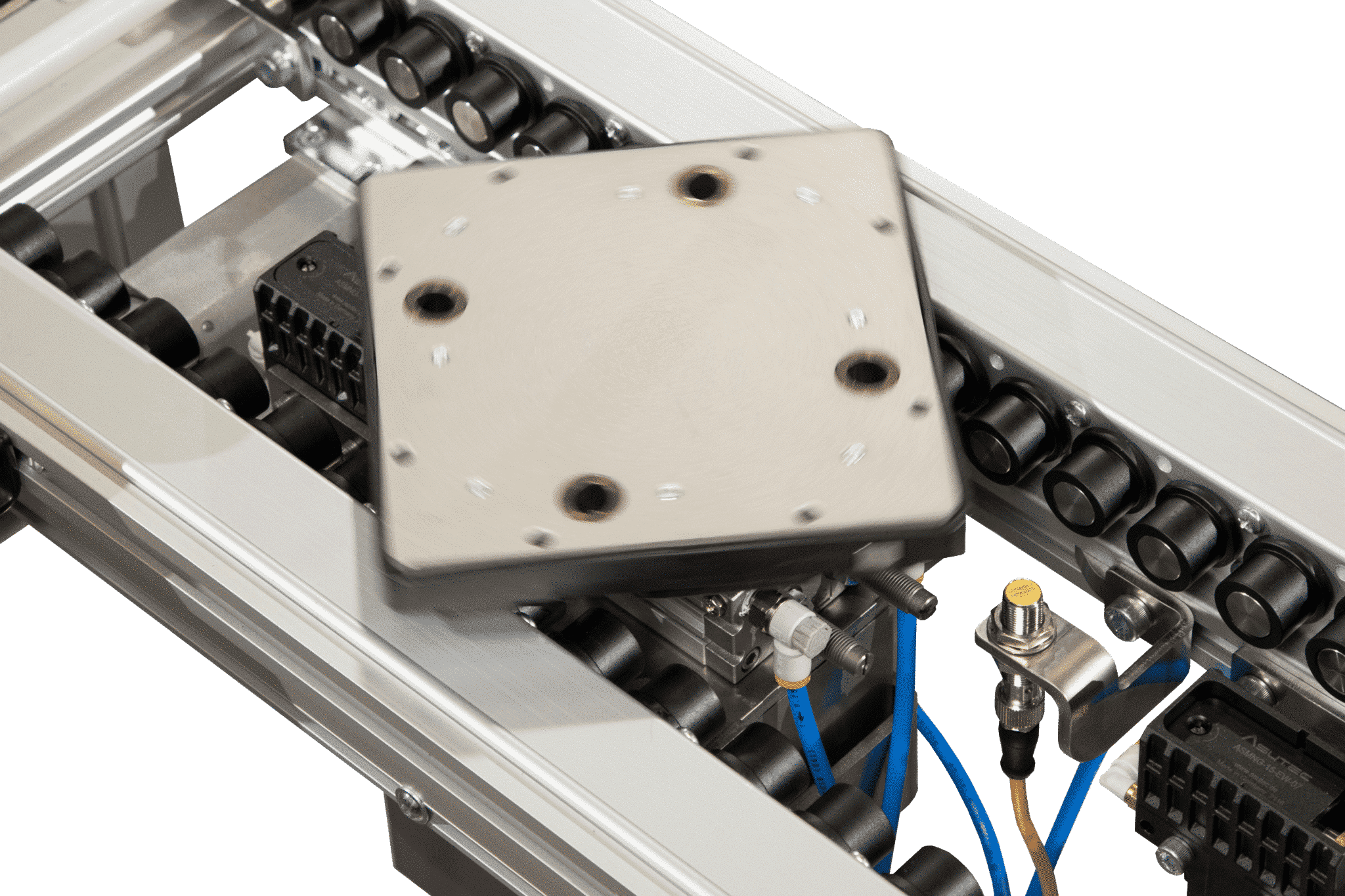

Pallet System Conveyors

Specifically designed to increase efficiency, reduce downtime in automation processes, and provide accurate conveying. Simplify product flow and control with features such as a unique pin tracking system, industry compatible pallet sizes and innovative modules.

Ready to optimize your production processes?

Contact us and let’s find the best solution for your application together.

Our Services

We not only provide high-quality conveyor systems but also offer top-notch service and support. Our team provides a wide range of services to ensure your system operates smoothly:

Training

We train your team in the use and maintenance of the systems to minimize downtime.

Aftermarket Support

We are here for you throughout the entire lifespan of your conveyor system.

Maintenance

We offer tailored maintenance programs, including inspection, adjustment, lubrication, and more.

Our Quality Commitment

At Dorner, we are dedicated to the highest quality and continuous improvement. As a leading manufacturer of conveyor technology solutions worldwide, we provide solutions that not only meet but exceed our customers‘ requirements. Our ongoing pursuit of exceptional

products and services extends to all our offerings.

ISO Certification

We are certified to ISO 9001:2015, highlighting our commitment to quality and continuous improvement of our products.

Industry Certifications

Dorner conveyors comply with a variety of industry requirements and regulations, including USDA, BISSC, CE, and cleanroom certifications

FAQ

Dorner offers a wide range of conveyors designed to meet different requirements and industries:

GAL/GES: offers innovative conveyor belt solutions for streamlined production. We provide high-quality indoor systems using durable materials such as aluminum, steel, and stainless steel.

Miniature Conveyors: These conveyors feature a low profile and are ideal for pharmaceutical and medical applications. They enable the precise and efficient transport of small or lightweight parts.

Low-Profile Conveyors: The 2200 Series conveyors are perfect for applications with limited space, providing flexibility for small to medium-sized parts and adaptable layouts. They are commonly used in metalworking, medical, packaging, and various industries.

Heavy-Duty Conveyors: The 3200 Series conveyors are designed for transporting medium to heavy parts and bulk handling. They offer high speeds and long runtimes, making them ideal for automated and manual assembly processes.

Sanitary Conveyors: These conveyors are specially designed for the food industry, complying with strict hygiene requirements and quality standards. They ensure the safety and quality of your food products.

Dorner has developed comprehensive conveyor solutions tailored to the requirements of various industries. Our wide range of conveyors and systems allows us to provide customized solutions for the following industries:

E-commerce: Specialized conveyor solutions for secure, precise, and timely handling of packages and shipments in the e-commerce market.

Metalworking: Flat industrial conveyors for numerous metal processing applications, including stamping, cutting, shaping, and assembly.

Medical Applications: Conveyors that meet the demands of medical manufacturing, from cleanroom production to fully automated production.

Material Transport & Industry: Conveyor technologies to support the transport and handling of products in various industries, from small to large parts.

Packaging: Dorner products enhance packaging efficiency through fast and efficient conveyors that offer customized solutions.

Medical Applications: Conveyors that meet the demands of medical manufacturing, from cleanroom production to fully automated production.

Food Industry: Sanitary conveyors enabling the handling of raw meat to packaged foods, meeting industry regulations such as FDA, BISSC, and USDA.

Automation: Custom conveyor solutions to optimize production processes in various industries.

Our solutions are tailored to meet the specific requirements of each industry and enhance efficiency.

There are various types of conveyor materials, each suitable for specific requirements and applications. Here are some key conveyor materials: Fabric Conveyors: These conveyors are flexible and allow for small roller diameters, simplifying integration and product handling. They come in various weights and materials, with woven and non-woven variants.

Fabric Conveyor Belts are used in a variety of applications, from lightweight to heavy-duty processing in industries such as material transport, automation, and FDA-compliant food processing.

Modular Conveyor Belts: Made of plastic, these conveyors are durable, easy to clean and disinfect, and simple to maintain and repair. They prevent fraying, delamination, and connecting. Chain conveyors find applications in industries like bakery, food processing, manufacturing, and more. They can be available in different configurations such as hinge belt and mat chain belt.

Flexible Chains: Also known as tabletop chains, these chains are ideal for complex layouts and various environments. Flexible chains have a joint running in the middle of the conveyor, leaving the sides of the belt completely open. This allows for the use of the entire conveyor width and provides more flexibility in product handling. These durable belts are commonly used in filling, secondary packaging, automation, general manufacturing, and more.

Selecting the right conveyor material depends on various factors, including:

Temperature: Depending on whether the conveyor is used in cold or hot environments, certain materials are better suited. For example, silicone is suitable for high temperatures, while polyethylene is suitable for low temperatures.

Abrasion Resistance: When handling items that could cause wear on the conveyor, abrasion resistance is crucial. Materials like polyurethane and nitrile butadiene rubber are highly rated for their abrasion resistance.

Additional Considerations: include surface material, friction level, static conductive or antistatic properties, chemical resistance, FDA approval, V-guiding, and color preferences.

It’s important to choose the right material based on your specific requirements to ensure an efficient and reliable conveyor solution. Dorner offers a wide range of conveyor materials and configurations to meet the needs of various industries.

With the vast variety of materials, configurations, accessories, and sizes, choosing a conveyor system can be an overwhelming task. Dorner Conveyor Systems are experts at delivering and developing a conveyor that will work for you. Get exactly what you need by exploring each type of conveyor available, including:

- Product types for conveyors

- Belt types

Size and weight of the product

Material of the product

Direction of the conveyor–incline or decline

Speed needed to move the product

- If the product’s orientation will change throughout the conveying process

Narrowing down these options is what establishes your conveyor as the perfect solution for your business. Understanding all of the above will help you better understand your product, the environment it needs, and therefore the proper conveyor system to transport it.

For more information about how to customize a conveyor for your needs, fill out the form above or download our conveyor infographic here.

Still have questions?

Our team is at your disposal to answer your questions and find an optimal solution.