- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Medical Industry Conveyors

Conveyor Systems for Medical Equipment Manufacturing and Packaging

Enhance Your Medical Manufacturing and Packaging Operations With Conveyor Systems From Dorner

- Masks

- Bandages

- Gauze

- Vessels

- Syringes

- Razors

- Surgical instruments

- Plastic containers

- Test kits

- Feminine Products

- Wipes

- Bulk packages

- And more

Efficient, Sterile Transportation Solutions for Manufacturing Medical Devices

Manufacturing individual parts and assembling medical devices demands the highest standard of precision and repeatability. Conveyor systems from Dorner are adept at handling all stages of medical device production, from assembly and inspection to medical device packaging.

Integrate Dorner conveyors to improve the efficiency, consistency, and precision of your medical parts manufacturing, assembly, and packaging operations.

- Implantable devices

- Imaging equipment

- Monitors

- IV diagnostics tools

- Surgical instruments

- And more

Our Cleanroom-Verified Conveyors for Medical Products Manufacturing and Packaging

*To verify clean room requirements, an unloaded base conveyor was tested and did not generate particulate that would be beyond the specified standards. However, the verification does not provide assurance that any or all applications will meet this requirement. Application testing is recommended to ensure clean room standards are being met. Dorner takes no responsibility in the clean room performance of the final conveyor or application.

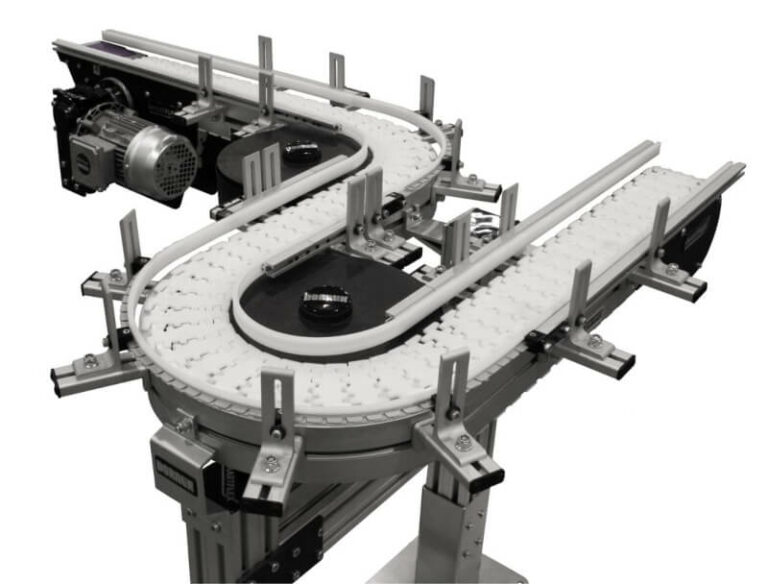

FlexMove

- Part handling

- Tight spaces

- Assembly automation

- Machine conveyance

- Elevation changes

- Buffering

- Complex configurations

- Long lengths

- Curves, jogs, inclines, and declines

2200 Series Conveyors

Dorner’s 2200 Series Conveyors feature low-profile, high-performance fabric and modular belt conveyors with a high-speed nose bar transfer option, durable single-piece frame design, universal T-slots and range of belting and guiding options suitable for medical supplies manufacturing and packaging.

- Small- to medium-part handling

- Transfers

- Accumulation

- Precision parts movement

- Part incline/decline routing (Z frames)

- Positioning

- Automated and manual assembly

1100 Series Conveyor

- Flush frame allowing for side transfers

- T-slots for mounting accessories

- Pinch drive design which virtually eliminates belt stretching

- Optional back-light for inspection and quality control

AquaGard LP

- Washdown rated controls and gearmotors

- Stainless steel frame, plates, and bearings

- Low-profile design

- Quick belt change

- FDA approved belting options

ERT150

- Assembly automation

- Parts transfer

- Sortation

- Packaging

- Accumulation

- Tight spaces

- Simplified traffic control

Plastic Medical Products Require Dorner Medical Conveyors

Dorner the innovative FlexMove Helix conveyor, designed for efficient accumulation and product elevation. This system easily integrates into a larger production and other processing equipment. See the FlexMove Helix in action, where it proved to be an ideal solution for buffering delicate medical devices between steps in production.

Custom Conveying Solutions for Medical Supplies and Medical Device Manufacturing Companies

Tailored to Your Needs

Optional Features

- Conveyor covers

- Chutes

- Deviators

- Fully automated controls

- Factory trained installation

Maximize the Production of Your Healthcare Packaging and Manufacturing With Dorner Conveyors

Conveyors Medical Industry Conveyors

2200 Belted Conveyors

- Stronger, improved frame design

- New frame widths with single piece frame for widths 12″ and under

- Improved bedplate durability with hard anodized frame coating

- Universal T-slots fit industry standard hardware

- Updated drive and idler tails for easier belt install and shaft position change

- New 5/8″ high speed nosebar with speeds up to 200 fpm

- Adjustable guiding with new modern design and improved clamp method

- New guide accessories

- New belt options

2200 Modular Belt Conveyors

- Ladder-style, open frame construction for water and chemical drainage and air cooling.

- All belts fully contained in UHMW guiding for maintenance free tracking.

- Universal T-slot for ease and flexibility of adding accessories using industry available hardware.

- Additional frame widths and expanded guiding and chain options.

- Consolidated motor & control offerings.

1100 Miniature Belt Conveyors

- Small or light weight product movement

- Medical

- Pharmaceutical

- Life sciences

FlexMove Conveyors

This flexible powered conveyor offers a flexible, high-performance conveying solution that is easy to configure and reconfigure. Suited for tight spaces, elevation needs, long lengths, and more, the FlexMove flexible conveyor belt system is a versatile option designed to help you maximize your efficiency.

FlexMove Stainless Conveyors

- Stainless Steel Construction is ideal for corrosion resistant applications or packaging lines

- Provides capability for vertical incline with minimal floor space

- Features modular framing for future add-on capability and production line changes

- FlexMove Solutions eliminates unnecessary cutting, inventory and waste

Dorner — Asia

Dorner (M) SDN. BHD.

128 Jalan Permatang Damar Laut, Bayan Lepas 11960

Penang, Malaysia

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy