Dorner has come a long way since opening the doors in 1966. Starting a tool and die shop in the ’60s, the Dorner brothers had no idea that they would quickly transition into one of the most innovative producers of low-profile precision conveyors in the industry. From the first conveyor created as a solution for a common challenge in the tool and die industry, Dorner has built a family of conveyance systems to offer custom solutions and meet the needs of a wide variety of industries.

The Low Profile 4100

Removing scrap and parts from under die machines was a challenging and time-consuming process in the 1960s, requiring machines to be turned off at regular intervals so operators could safely remove parts manually. This made the machining process slow and laborious. A simple solution would be to add a conveyor under the machine to move product out as it was completed, but there were no conveyors on the market small enough to fit under the die and between the bolsters.

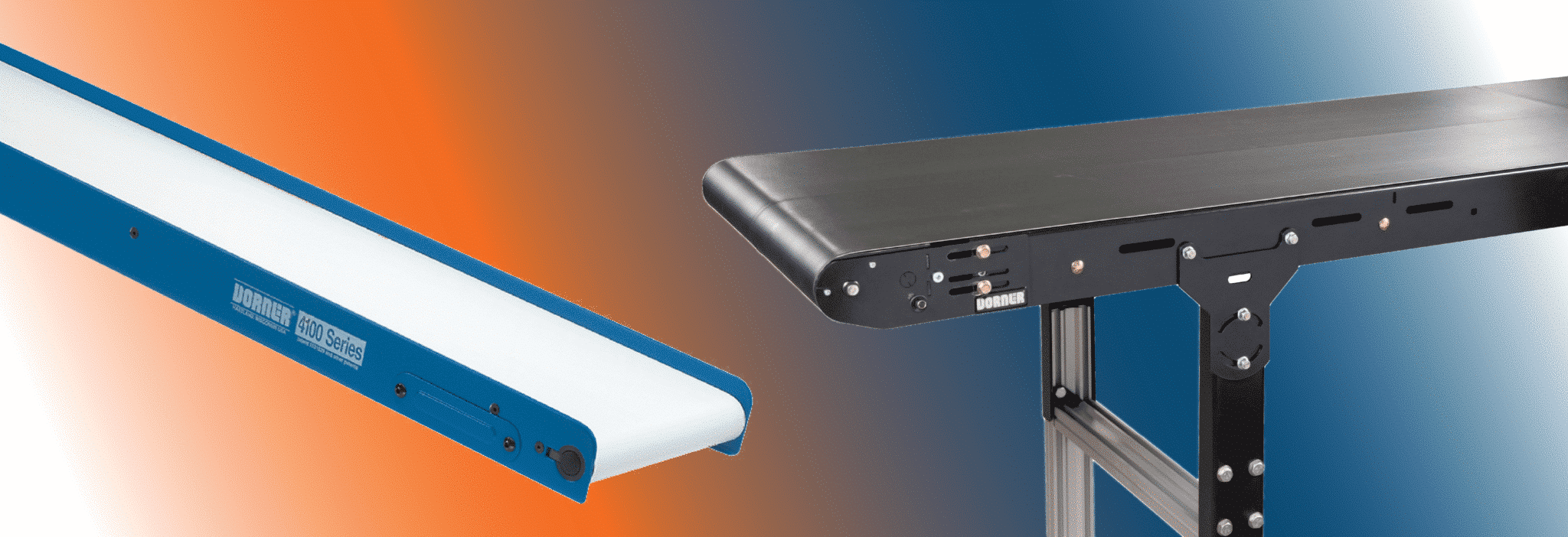

With some creativity and innovative engineering, the Dorner brothers created a low-profile conveyor with radial thrust bearings, custom designed belting, and a narrow, painted steel frame to fit below their own machines. In 1973, the Low Profile 4100 (also known as the Slug-O-Matic) was born and made available to the wider tool and die industry to utilize. Before too long, the 4100 conveyor was Dorner’s most popular product and facilitated a shift for the company to move into the world of low-profile conveyors.

From Steel to Aluminum

Dorner’s conveyors quickly transitioned to a light-weight extruded aluminum frame design for better flexibility and an improved design with T-Slot accessory mounting. From the original low-profile concept of the 4100, we released the highly precise and low profile 2200 series conveyor and the heavy duty 3200 series. Seeing a need for higher precision conveyance, Dorner continued to improve and expand our conveyor offering with unique designs and features that better served various applications from industrial material handling and automated manufacturing to food handling and pharmaceutical processing.

Back to our Roots with the DCMove

The 4100 was recently retired after over 50 years on the market, but that doesn’t mean we’ve forgotten about our first ever conveyor. Featuring an updated painted steel frame, the newest product from Dorner has the same durability and economic value as the 4100. With an improved design and modern features, the DCMove Belted Conveyor offers the perfect conveyance solution for material handling and logistic applications. The DCMove carries with it the legacy of the 4100, while providing customers with a truly innovative option for their conveyance needs.

The Innovating Never Stops

If there’s anything we’ve learned in our 57 years in business, it’s that technology is always improving and the industries we serve will always have challenges that need creative solutions. Dorner’s team of conveyor experts will continue to expand our offering and position ourselves at the forefront of the ever-evolving conveyor automation technology.