Recently, Dorner Europe helped create a unique conveyance system for Pfeifer & Langen, a leading sugar manufacturer in Europe. The… Read more »

Category: Uncategorized

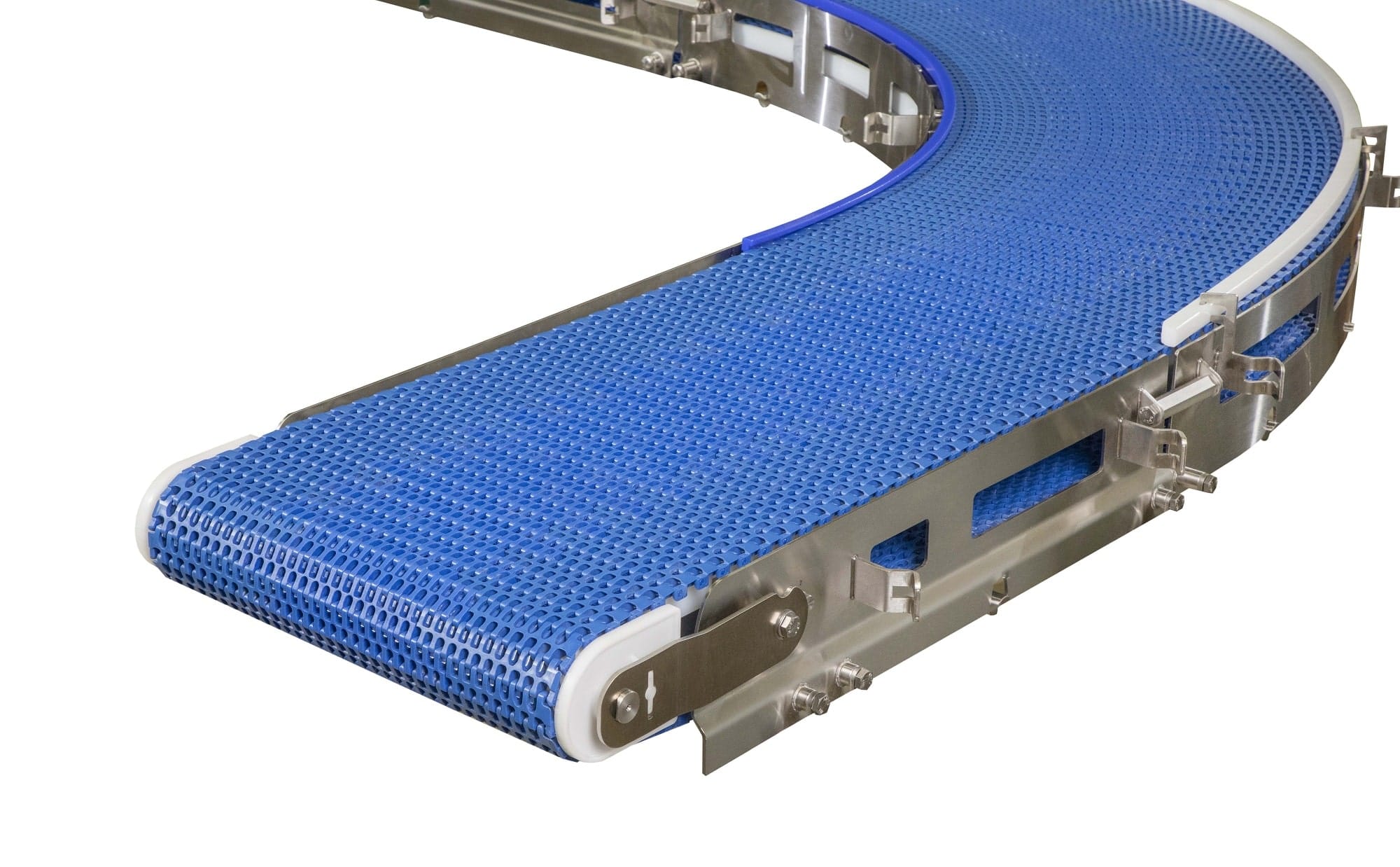

Application Study: Enhancing Raw Meat Production with Dorner’s AquaPruf Conveyor Overview

Leading meat producers are continuously challenged to improve production line efficiency while adhering to the stringent hygiene standards of the… Read more »

Efficient, Fast, and Aesthetic Preparation: Dorner Conveyor in Kitchen Use

To provide the perfect evening for large parties at the Hotel-Gasthof Adler in Bad Wörishofen, Bavaria, it is essential to… Read more »

Automate 2023: Booth Preview

Dorner is displaying four of its major automated assembly conveyor platforms – the FlexMove Pallet System, Edge Roller Technology ERT®250… Read more »

How Dorner is Overcoming Supply Chain Challenges

2022 is proving to be another year of significant supply chain challenges both for raw materials and manufactured goods,… Read more »

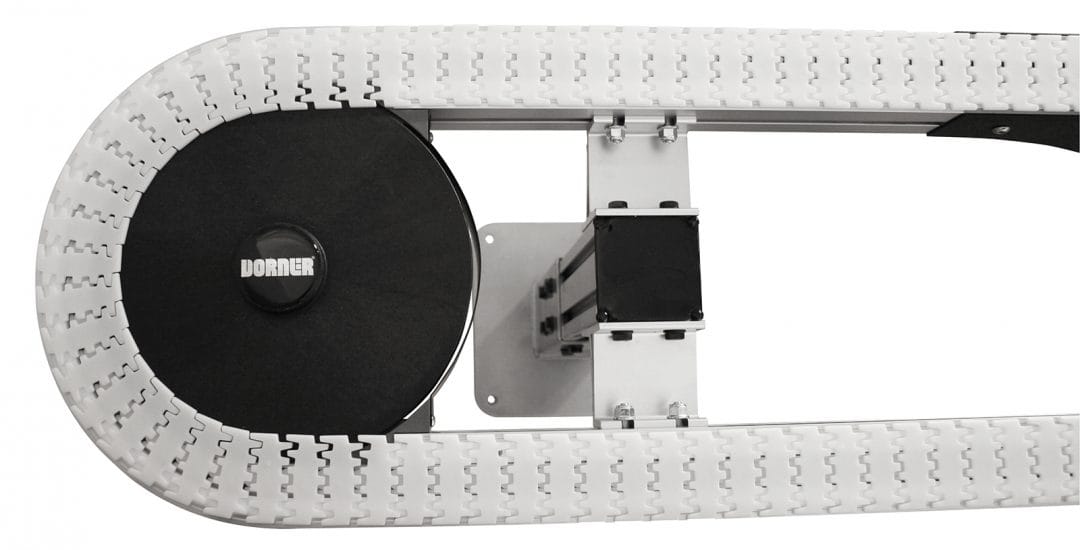

Dorner presenta el nuevo transportador FX de la línea FlexMove

Un transportador de cadena flexible con anchos de banda más amplios y más capacidad de carga para el mercado latinoamericano… Read more »

AquaPruf Conveyors in Action

Dorner’s AquaPruf Sanitary Conveyors feature industry leading designs, ensuring the latest technology in food safety. Take a look at the… Read more »

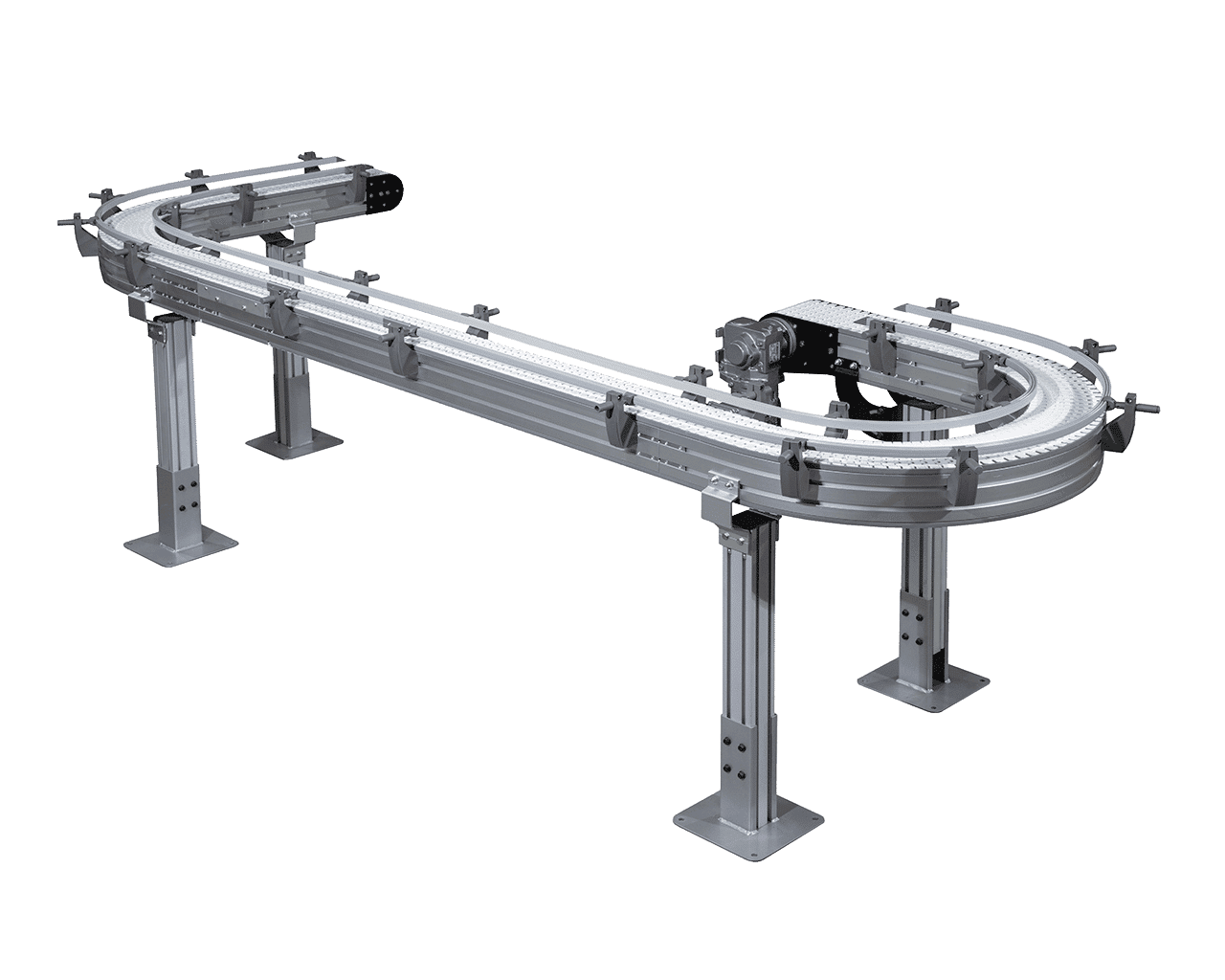

Dorner Engineered Solution – Recirculating Conveyors

Manufacturing lines require mechanical solutions to facilitate the consistent flow products to maximize throughput, and recirculating conveyors are a… Read more »

10 Reasons AquaPruf Conveyors Are Now Better Than Ever

Dorner’s AquaPruf redesign was based on what our customers told us they need in a stainless steel, sanitary conveyor.… Read more »

Are You Losing Time on Sanitation?

If you’re in an industry that requires high levels of sanitation, such as dairy, processed foods, beverages or pharmaceuticals,… Read more »

7 Reasons to Join the Dorner Team

Our people are the driving force behind our success and we’re looking for more amazing team members! We know… Read more »

Are You Neglecting Your Tails?

This month, stock up on replacement tail kits and get the belt at 55% off! Did you know that the… Read more »

Dorner ahora hace parte de Columbus McKinnon

Nos complace anunciar que Dorner ha firmado un acuerdo para ser adquirido por Columbus McKinnon (CMCO), líder mundial en… Read more »

What You Need to Know to Choose the Right Belt

Have you been thinking about purchasing a conveyor, but don’t know how to decide which type of belt is… Read more »

Cleaning Tips for Industrial Conveyors

While customers are often familiar with cleaning and sanitizing stainless steel sanitary conveyors, which are built for daily wipe downs… Read more »

We Are In This Together

Now more than ever we stand together with the businesses that are essential to the fabric of our communities.… Read more »

New Service Videos Now Available – AquaGard 7350 Series

Do you have a new AquaGard 7350 Series Modular Belt Curve conveyor you need to install? Or do you need… Read more »

Four Ways to Maximize Packaging OEE with Flexible Solutions

According to PMMI’s State of the Packaging Industry 2019 the value of US packaging shipments is forecasted to… Read more »

Three Conveyors at Pack Expo East That Will Meet Growing Production Demands

Heading into PACK EXPO EAST the Global Food Packaging is reaching all new heights. According to PMMI, the industry… Read more »

Dorner Continues its European Expansion by Building 2200 Series LPZ Conveyors from its German Manufacturing Facility

Hartland, Wis., (February 26, 2020) — Dorner GmbH is expanding its presence throughout Europe by adding the 2200 Series LPZ… Read more »

AquaGard and AquaPruf Conveyors Earn BISSC Certification for their High Sanitary and Safety Attributes

Dorner’s AquaGard and AquaPruf sanitary conveyor platforms have again earned the coveted Baking Industry Sanitation Standards Committee (BISSC) certification… Read more »

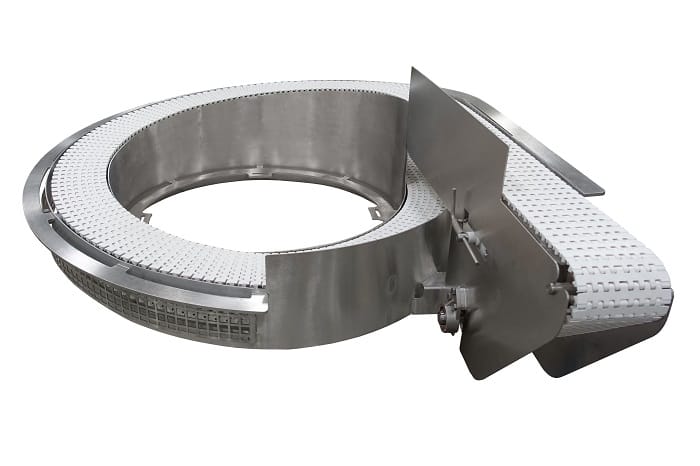

Sanitary Helix Now with Added Features

As we’ve highlighted in the past, Dorner has created Sanitary Helix designs to integrate with Hoosier Feeder’s Food Grade Centrifugal… Read more »

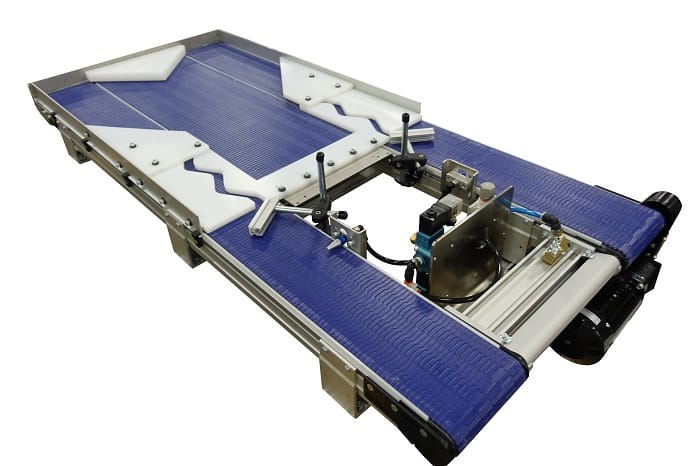

Custom Accumulation Systems

When you need to ensure a steady supply of product to a machine or to hold a supply of product… Read more »

Magnetic Conveyors Customized for Efficiency

Every business needing a magnetic conveyor in its facility has a specific product to run. Therefore, no two solutions… Read more »