- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Optical Industry Conveyor Solutions

Optical Industry Conveyor Solutions From Dorner Conveyors

In optical manufacturing, precision, hygiene, and flexibility are paramount. At Dorner, we understand the unique challenges facing this specialized sector, from eyewear production to advanced optical instruments. Our innovative conveyor solutions are engineered to handle the full range of optical manufacturing needs, from delicate lenses to complex frames. These systems are designed to streamline your processes, enhance product quality, and boost overall efficiency.

Benefits of Dorner Conveyors for Optical Manufacturing

✓ Increased Precision and Efficiency

✓ Enhanced Product Quality

✓ Superior Cleanliness

✓ Cost Savings

✓ Employee Safety

✓ Adaptability

✓ Reliable Performance

Applications of Dorner Conveyors in Optical Manufacturing

Material Handling

Lens Processing

Frame Assembly

Quality Control

Packaging and Labeling

Dorner's Conveyor Solutions for Optical Manufacturing

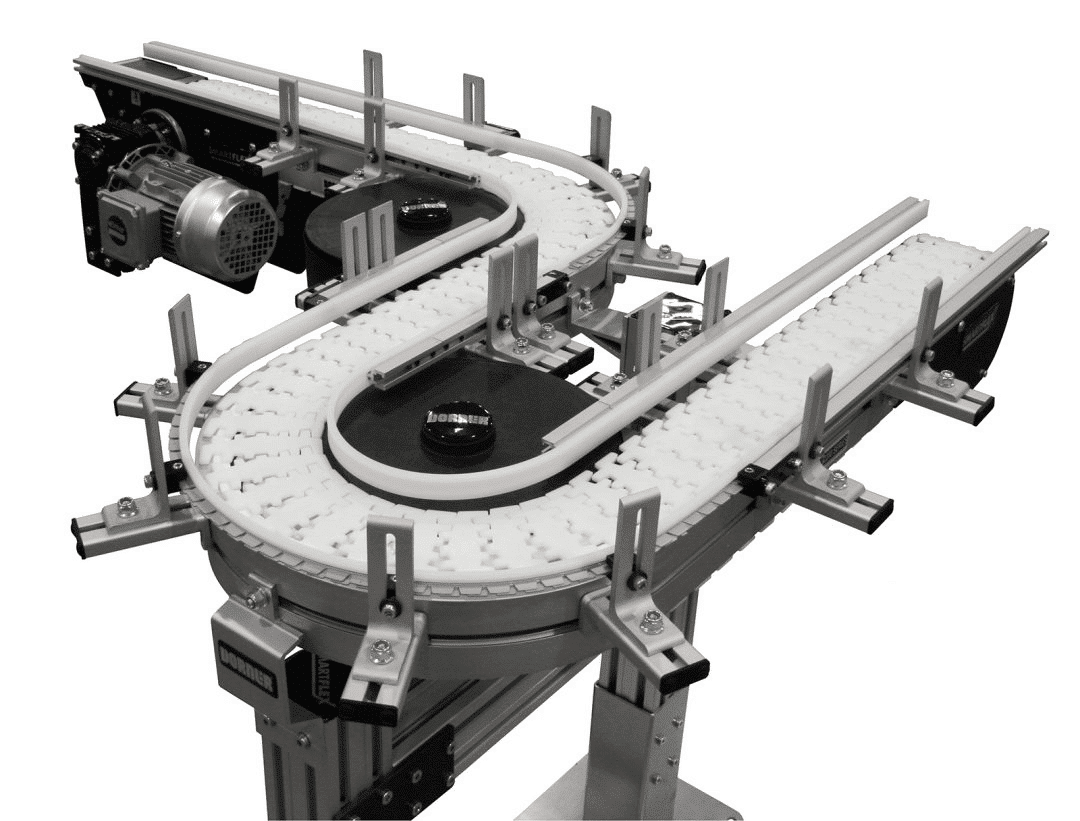

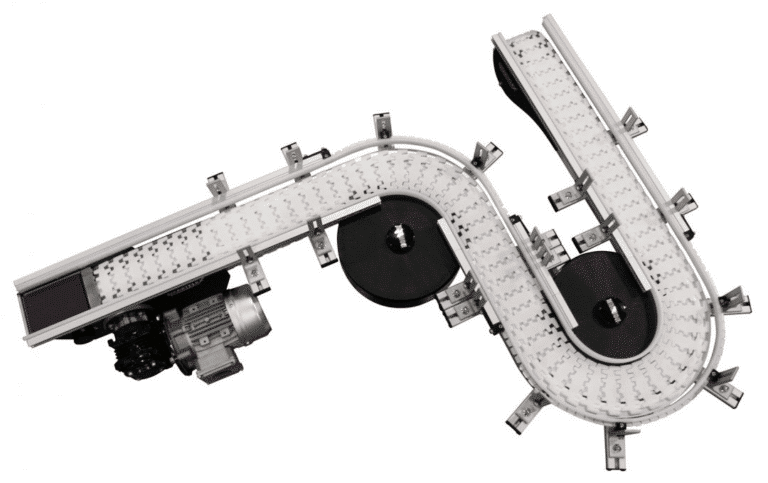

FlexMove Conveyors

montrac® Shuttle Conveyors

montrac® system is another ideal solution for the optical industry. This modular automation and transport system provides vibration-free handling of delicate optical components, flexible layout options for tight spaces, and on-board power for processing during transport. Its anti-static features and customizable design make it perfect for sensitive electronic components in optical devices. montrac® optimizes material flow and enhances productivity in optical manufacturing without requiring additional machinery, making it a valuable asset for streamlining production processes.

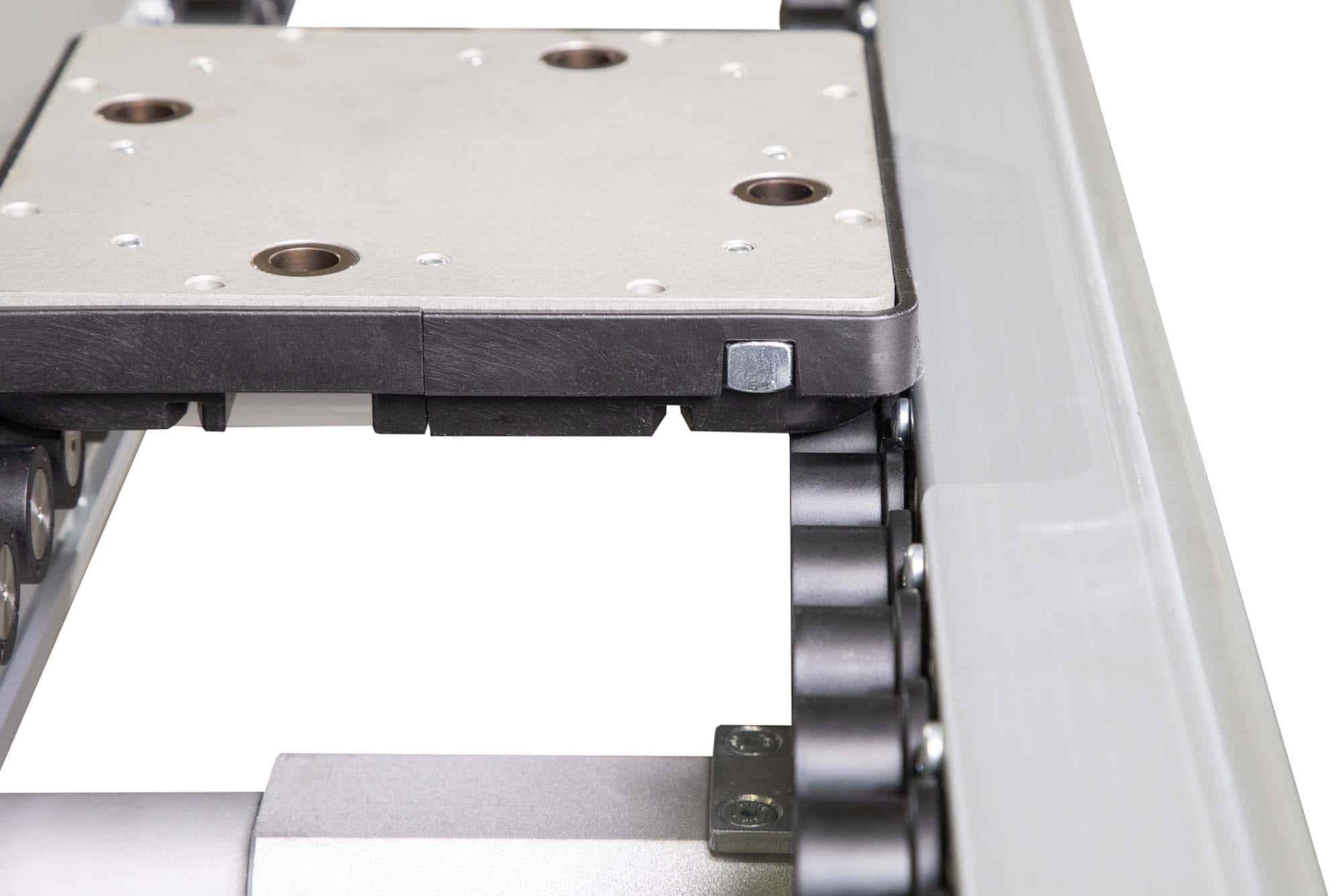

ERT150 Pallet Conveyors

Dorner’s ERT150 pallet conveyors offer precision conveyance solutions for optical production lines. The belt-free, open-frame design makes this conveyor system ideal for automated production lines in cleanroom environments. The ERT150 can be adapted to different production processes with various modules and custom zoning capabilities.

Low Profile Belted Conveyors

The low-profile 2200 and miniature 1100 conveyor systems seamlessly integrate with other processing equipment to transport lenses through dryers, curing processes, or inspection operations. With transfers as small as 3mm, Dorner’s belted conveyor solutions reduce potential product loss, and ensure accurate pacing throughout the production line.

Top Optical Manufacturing Segments Benefiting from Dorner Conveyors

Prescription Eyewear Production

Contact Lens Manufacturing

Sunglasses and Fashion Eyewear

Safety and Sports Eyewear

Optical Lenses for Cameras and Instruments

Ophthalmic Equipment Manufacturing

Vision Testing Devices

Lens Coating and Treatment

Frame Design and Production

Optical Laboratory Equipment

Partnering with Dorner for Optical Manufacturing Success

Customized Solutions

Expert Guidance

Comprehensive Support

Continuous Improvement

Your Partner for Optical Manufacturing Solutions

Contact Us

Frequently Asked Questions

How can Dorner Conveyors streamline optical production?

Can Dorner Conveyors handle specific optical materials?

How does Dorner ensure conveyor safety in optical manufacturing?

What conveyor support does Dorner provide for optical manufacturers?

Dorner — Germany

Columbus McKinnon Industrial Products GmbH

Karl-Heinz-Beckurts-Straße 4

52428 Jülich, Germany

+49 (0) 2461/93767-0

info.europe@dorner.com

Dorner — France

8 rue des Frères Caudron

78140 Velizy-Villacoublay

France

+ 33 (0)1 84 73 24 27

info.france@dorner.com

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy