In modern manufacturing, maximizing production efficiency while minimizing downtime is crucial for maintaining a competitive advantage and meeting customer demand. But how exactly do accumulation conveyors improve assembly line throughput?

Accumulation conveyors improve assembly line throughput by creating buffer zones that prevent line stoppages, allowing continuous production flow even when individual workstations experience brief delays or interruptions, typically increasing efficiency by 15-30%.

While this basic explanation covers the fundamental benefit, it’s important to understand that different types of accumulation conveyors offer varying advantages depending on your specific manufacturing setup and production goals. Knowing which type best suits your needs could make the difference between a modest improvement and a dramatic boost in productivity.

What Are Accumulation Conveyors?

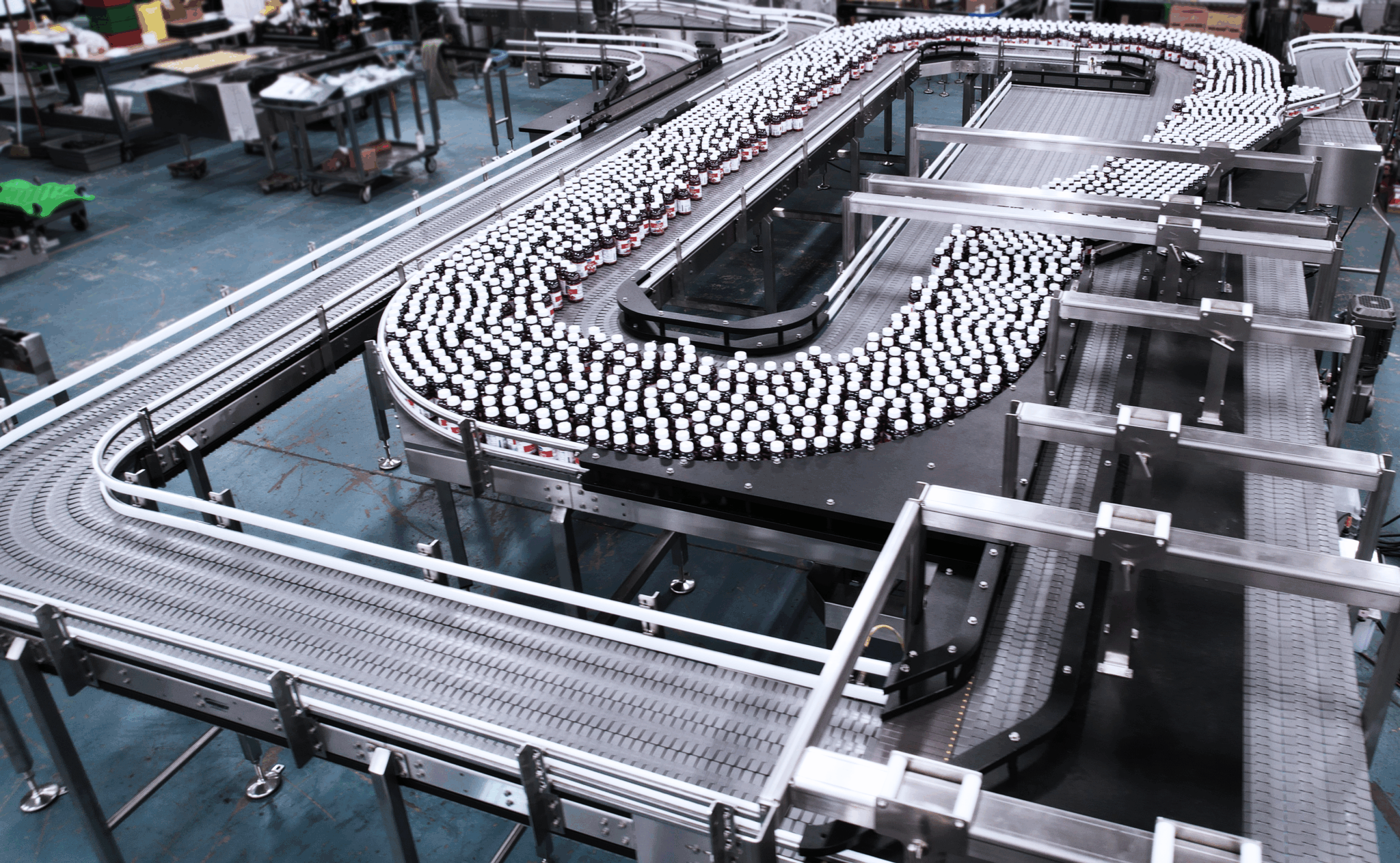

Accumulation conveyors are specialized material handling systems designed to temporarily store products between different stages of production. Unlike standard conveyors that move products at a constant speed, accumulation systems can slow down, stop, or create temporary storage zones without halting the entire production line.

These systems serve as strategic buffers between workstations operating at different speeds, ensuring that a slowdown at one station doesn’t negatively impact the speed of the entire production line. By creating controlled queues of products, accumulation conveyors help maintain a steady flow and maximize overall system throughput.

The Problem: Micro-Stops and Speed Variations

Understanding Micro-Stops

Micro-stops are brief interruptions lasting seconds to minutes that occur throughout assembly lines. Common causes include:

- Quality inspections that require temporary product holds

- Tool changes or minor adjustments at workstations

- Operator breaks or shift changes

- Material replenishment at individual stations

- Equipment calibration or minor maintenance tasks

- Line backups due to slower machine throughput in downstream processes

While individually small, these micro-stops can cascade through an assembly line, creating significant throughput losses when stations are rigidly connected.

Speed Variation Challenges

Different manufacturing processes naturally operate at varying speeds:

- Manual assembly stations may have natural human pace variations

- Automated processes might run at different cycle times

- Quality control checkpoints require variable inspection times

- Packaging operations often need flexibility for different product sizes

Without proper buffering, the entire line must operate at the speed of the slowest station, severely limiting overall productivity.

How Accumulation Conveyors Solve These Problems

1. Creating Strategic Buffers

Accumulation conveyors create intelligent buffer zones between production stations. When a downstream process slows down or stops temporarily, products accumulate in these buffer zones rather than backing up the entire line. This allows upstream processes to continue operating at optimal speeds.

Key benefits include:

- Upstream stations maintain productivity during downstream delays

- Reduced overall line stoppages

- Better utilization of equipment and labor

- Smoother production flow

2. Speed Decoupling Between Stations

By implementing accumulation zones, manufacturers can decouple the speeds of different production stages. This means:

- Fast processes aren’t held back by slower operations

- Slow processes aren’t overwhelmed by faster upstream production

- Each station can operate at its optimal efficiency level

- Overall line speed increases significantly

Industry reporting on how different accumulation methods maintain full-speed flow reinforces the importance of matching conveyor type—whether medium pressure, zero pressure, or zero contact—to the needs of each production process.

3. Absorbing Variation and Maintaining Flow

Accumulation systems act like shock absorbers for production variations:

- Temporary slowdowns are absorbed without affecting the entire line

- Speed bursts from efficient operations are captured and smoothed out

- Maintenance windows at individual stations don’t halt production

- Quality holds affect only the specific products, not the entire flow

Types of Accumulation Conveyor Systems

Zero Pressure Accumulation (ZPA)

Zero-pressure accumulation is widely used to prevent product contact and maintain smooth flow. A recent piece on choosing the right accumulation conveyor for high-throughput lines highlights how careful zone design supports faster production while reducing product damage.

Advantages:

- Gentle product handling ideal for medical applications

- No product contact during accumulation

- Easy integration with existing systems

- Suitable for fragile or delicate items

Belt Accumulation Systems

Modular belt accumulation systems offer flexibility and can handle various product types while providing smooth accumulation and release.

Features:

- Versatile product handling

- Easy cleaning and maintenance

- Customizable configurations

- Suitable for food and pharmaceutical applications

Measuring Throughput Improvements

Key Performance Indicators

When implementing accumulation conveyors, manufacturers should track:

Overall Equipment Effectiveness (OEE):

- Availability improvements from reduced line stops

- Performance gains from speed optimization

- Quality maintenance through controlled handling

Throughput Metrics:

- Units per hour increases

- Cycle time reductions

- Buffer utilization rates

- Station efficiency gains

Operational Benefits:

- Reduced downtime duration

- Improved labor productivity

- Better equipment utilization

- Enhanced production scheduling flexibility

Real-World Impact

Many manufacturers report significant improvements after implementing accumulation systems:

- 15-30% increase in overall throughput

- 50-70% reduction in line stoppage frequency

- 20-40% improvement in OEE scores

- Faster ROI through improved productivity across e-commerce operations

Implementation Considerations

Sizing Accumulation Zones

Proper sizing of accumulation zones is critical for maximum effectiveness:

- Buffer capacity should accommodate typical variation patterns

- Length calculations must consider product dimensions and flow rates

- Zone quantities should match production bottleneck patterns

- Flexibility for future production changes should be considered

Integration with Existing Systems

Successful accumulation conveyor implementation requires:

- Control system integration for seamless operation

- Sensor placement for proper product detection

- Communication protocols between different line sections

- Operator training for optimal system utilization

Industry-Specific Applications

Different industries benefit from tailored accumulation solutions:

Manufacturing

Automotive assembly lines, electronics production, and consumer goods manufacturing all face natural cycle-time variations between stations. Accumulation conveyors buffer these differences to keep products moving efficiently.

Automation

Robotic pick-and-place operations and automated sorting systems rely on precise timing. Buffer zones allow robots to keep working even if a downstream process pauses.

Food & Beverage

Food producers often need gentle handling along with high throughput. A case study highlighted in Processing Magazine shows how smart conveyor designs can move frozen meals quickly without damage—an approach that parallels the benefits of well-designed accumulation systems.

These examples illustrate how strategic buffering supports both speed and product protection across a wide range of production environments.

Learn more about maximizing your production line with Garvey’s line analysis.

Choosing the Right Accumulation Solution

Factors to Consider

When selecting accumulation conveyor systems:

Product Characteristics:

- Size, weight, and fragility requirements

- Surface finish and contamination concerns

- Temperature and environmental considerations

Production Requirements:

- Throughput targets and variation patterns

- Available floor space and layout constraints

- Integration with existing equipment

Operational Needs:

- Maintenance accessibility and requirements

- Cleaning and sanitation needs

- Future expansion possibilities

CMCO’s Conveyance & Accumulation Solutions

CMCO’s Conveyance Solutions brands, Dorner and Garvey, offer comprehensive accumulation conveyor solutions designed for maximum efficiency:

FlexMove Systems provides flexible accumulation with:

- First-in-first-out accumulation flow

- Space-saving vertical accumulation & buffering solutions

- Flexible & customizable layout designs

- Intelligent motion controls integration

ERT Pallet Systems offer no-contact accumulation as well as:

- Customizable buffer zones

- Easy reconfiguration capabilities

- Gentle product handling

- Seamless integration options

Modular Belt Conveyors offer:

- Reliable accumulation performance

- Easy maintenance access

- Sanitary design options

- Scalable configurations

Precision Move Conveyors deliver:

- Accurate positioning for accumulation

- High-speed operation capabilities

- Robust construction for demanding applications

- Advanced control integration

The Future of Accumulation Technology

Smart Accumulation Systems

Modern accumulation conveyors increasingly incorporate:

- Predictive analytics integration to optimize buffer sizing

- Real-time monitoring of accumulation patterns

- Customizable control programing to adjust to changing conditions

- Integration with MES systems for production optimization

Industry 4.0 Integration

Accumulation systems are becoming key components of smart manufacturing alolng with:

- Data collection for continuous improvement

- Remote monitoring and diagnostics

- Predictive maintenance capabilities

- Flexible automation for changing product mixes

Maximizing Your Accumulation Investment

Best Practices for Implementation

To achieve maximum throughput improvements:

- Conduct a thorough line analysis to identify optimal accumulation points

- Size buffers appropriately based on actual production data

- Train operators on system capabilities and optimization techniques

- Monitor performance metrics continuously for ongoing improvement

- Maintain systems properly to ensure consistent operation

ROI Optimization

Maximize return on investment by:

- Targeting high-impact locations for accumulation installation

- Optimizing control strategies for your specific production patterns

- Regular performance reviews to identify additional opportunities

- Scaling implementation based on proven results

Optimize Your Line Today

Accumulation conveyors represent a proven strategy for dramatically improving assembly line throughput by creating intelligent buffers that absorb micro-stops and speed variations. With typical throughput improvements of 15-30%, these systems offer some of the highest ROI and productivity enhancements available to manufacturers.

For manufacturers looking to optimize assembly line performance, properly designed accumulation systems offer a clear path to improved efficiency, reduced downtime, and enhanced profitability. The key is working with experienced conveyor specialists who can design solutions tailored to your specific production requirements.

Whether you’re dealing with existing bottlenecks or planning new production lines, Dorner’s comprehensive conveyor solutions and Garvey’s advanced accumulation systems offer the flexibility and efficiency required to meet today’s demanding manufacturing requirements, while positioning your operation for future growth and success.