Know What You’re Getting Before You Buy

By John Kuhnz

Vice President, Engineered Solutions Group, Dorner Mfg.

There are many factors that drive food processors to upgrade their conveyor systems to a more sanitary platform. Leading the charge is the Food Safety Modernization Act (FSMA), which takes a more proactive approach toward food safety by adding safeguards to try  and prevent contamination or problems from occurring within the nation’s food supply in the first place. Besides the FSMA, companies cannot afford to have a contamination outbreak traced back to poor sanitary designs in their equipment. The risks to their reputation and to their customers’ well-being are too great.

and prevent contamination or problems from occurring within the nation’s food supply in the first place. Besides the FSMA, companies cannot afford to have a contamination outbreak traced back to poor sanitary designs in their equipment. The risks to their reputation and to their customers’ well-being are too great.

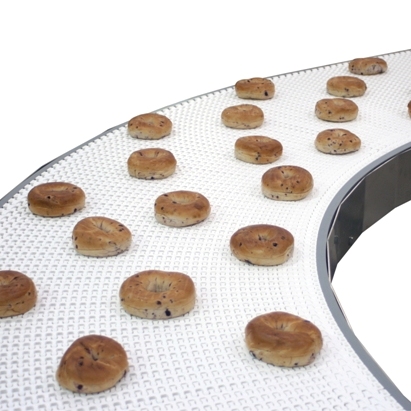

So as companies scrutinize how to improve their food processing practices and stay ahead of the FSMA, installing new sanitary conveyors is often one of the conclusions they arrive at. That’s a sound decision because conveyors are in direct contact with food, especially on the processing side. These conveyors need to be built with strong sanitary attributes to eliminate any chance of contamination. However, not all “sanitary” conveyors are built the same. Let’s take a look at some of the engineering and design differences that make a conveyor a truly sanitary platform.

Is Stainless Steel Truly Sanitary?

A common misconception is that all stainless steel conveyors are sanitary. When the FSMA was announced a few years ago, many companies went out and purchased stainless steel conveyors thinking they were going to get a high level of sanitary protection. While that purchase provided them with a stainless steel conveyor, they might not have received a truly sanitary conveyor…and there’s a big difference between the two. Here’s why:

Stainless steel is certainly the right material to use in applications that call for regular washings with light chemical cleaning agents. A basic stainless steel conveyor can be washed throughout the day as needed, depending on how it’s built, but it’s not necessarily sanitized. That’s because sanitizing a conveyor involves an entirely different process than simply washing it down, and much of achieving a sanitized conveyor depends on the way it was initially designed.

What Makes a True Sanitary Conveyor?

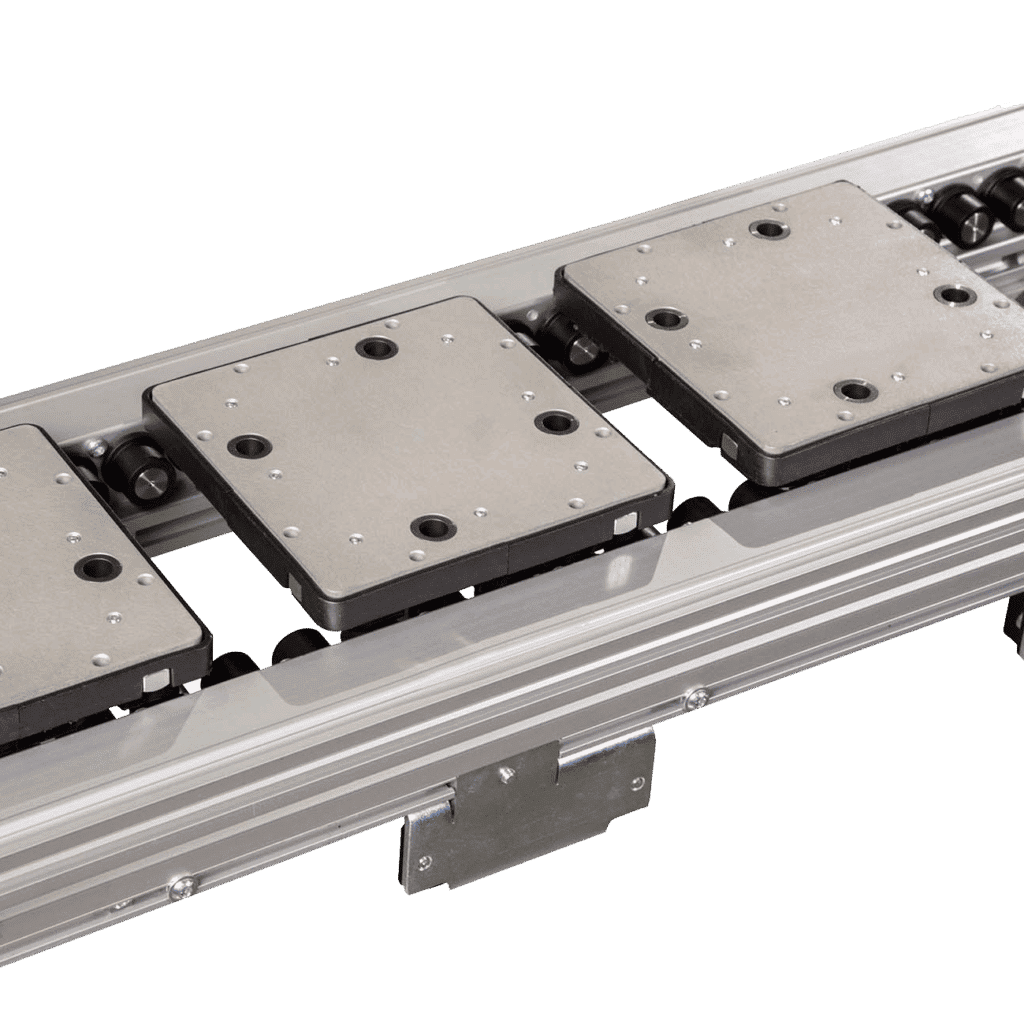

The goal of a sanitary conveyor is to, as best as possible, eliminate any chance of contamination. By their very nature, conveyors are an excellent source of contamination; especially on the processing side where raw food and ingredients are being moved. A sanitary conveyor works to eradicate those areas where contamination can happen…and that starts with the design of the frame.

A true sanitary conveyor gives the user full easy access to all areas of the conveyor for cleaning. By being able to reach every part of the conveyor with water, soap or other cleaning agents, there’s no chance of product collecting and growing into bacteria.

Additionally, a sanitary conveyor removes harbor points, blind spots and flat level surfaces within the frame structure, and replaces them with rounded cross members preventing food and water from accumulating. This design element is important because it doesn’t take long for components within the conveyor, like the motor, to begin heating up collected food particles and speeding up contamination. Also, the overall openness of the frame is designed so that any product that falls off the belt will land either in a catch pan below or on the floor; nothing gets trapped within the frame.

Other hygienic designs common in sanitary conveyors are the removals of plate-on-plate manufacturing on the frame. Often, these plate-on-plate designs involve sections of the frame bolted together with fasteners, and do not allow the user to take them apart for cleaning. This leads to food particles collecting in the crevices and spreading bacteria. Sanitary conveyors don’t have this type of manufacturing design. Rather, fasteners, which are harbor points for contamination, are removed from the conveyor’s food zone and

replaced with welds where necessary – again all aimed at making the conveyor as hygienic as possible. These proactive design elements of the conveyor mirror the philosophy of the FSMA in that both attempt to eliminate the sources of contamination before they have a chance to occur.

Different Levels of Sanitary

Also important to keep in mind when researching sanitary platforms is where in the plant the conveyor is located. For applications more downstream in processing where the conveyor is moving sealed and packaged food, the conveyor might not need to be as hygienic as those carrying raw food and ingredients.

Also important to keep in mind when researching sanitary platforms is where in the plant the conveyor is located. For applications more downstream in processing where the conveyor is moving sealed and packaged food, the conveyor might not need to be as hygienic as those carrying raw food and ingredients.

These conveyors often accumulate corrugated dust from the cardboard packaging, and that can be cleaned by washing or simply wiping down the conveyor. This conveyor is still sanitary in design, but for this application the more robust sanitary platform isn’t commonly required.

Education is the Key in Selecting the Right Sanitary Conveyor

A well-built sanitary conveyor will have these types of hygienic designs engineered into it. So the questions to ask when researching a sanitary conveyor system are:

- Where is the conveyor going to be located in your plant?

- How accessible is the conveyor to take it apart?

- Is it easy to disassemble and can it be performed by one person with no tools?

- Can you effectively wash and sanitize the conveyor because it’s designed properly?

- Is the conveyor truly going to meet your sanitary expectations?

Just because a conveyor is stainless steel doesn’t necessarily mean it’s engineered with these hygienic attributes. And that’s really the crux of the whole sanitary vs. stainless steel comparison; a lot more thought process from an engineering standpoint has gone into  the sanitary conveyor to make it truly a hygienic platform. The sanitary designs were considered upfront during the designing phase so that the conveyor will be much more productive for you once installed and operating in your facility. Understanding the different levels of sanitary standards available in conveyors will go a long way toward giving you peace of mind in knowing you’ve purchasing the right sanitary conveyor for your application.

the sanitary conveyor to make it truly a hygienic platform. The sanitary designs were considered upfront during the designing phase so that the conveyor will be much more productive for you once installed and operating in your facility. Understanding the different levels of sanitary standards available in conveyors will go a long way toward giving you peace of mind in knowing you’ve purchasing the right sanitary conveyor for your application.

John Kuhnz is the vice president of the Engineered Solutions Group, at Dorner Manufacturing. He can be reached at 262-369-1332 or john.kuhnz@dorner.com

Dorner Mfg. Corp. 2021. All Rights Reserved.