Battery Show North America is coming up fast, and the Dorner team is excited to showcase battery and electronics conveyor solutions with the rest of the CMCO Conveyance Group brands. The Dorner, Garvey, and montratec systems offer conveyance solutions for nearly every step in battery, EV, and electronics production. Our booth will also feature a guest display from fellow CMCO brand, Unified Industries, showing unique options for production applications needing ergonomic lifting solutions.

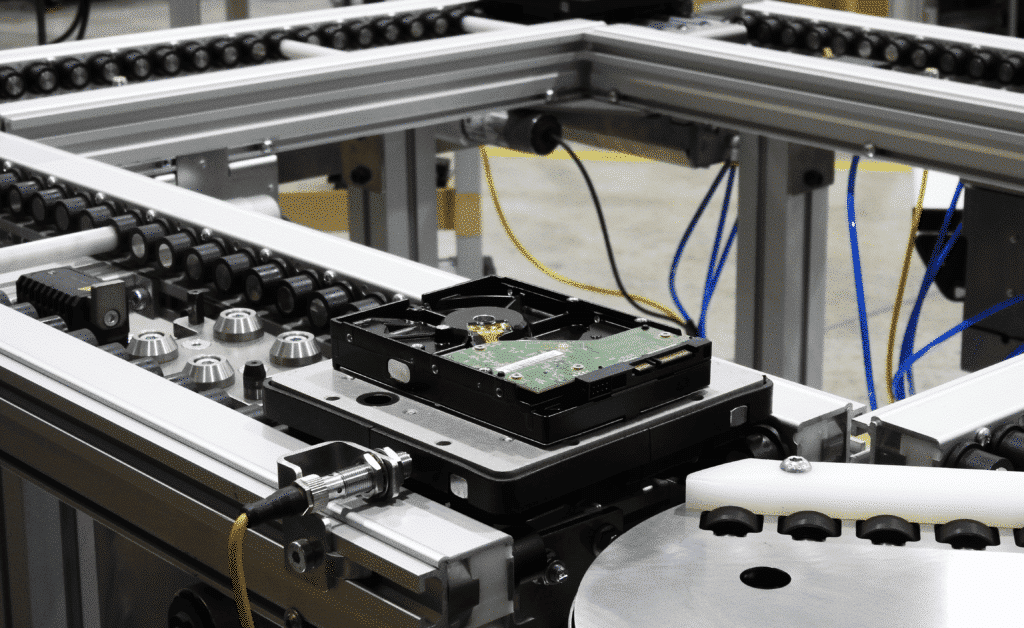

DualMove Pallet System

The first conveyance solution on display is the latest innovation from Dorner, the DualMove pallet system. This system uses twin timing belts to precisely transport and position pallets across automated and manual production lines. Its modular design and low-profile frame allow easy customization and adjustment to meet specific application needs. Whether you need to stack conveyors for a compact, high-output line or integrate it with robotic systems, the DualMove offers an ideal solution. The enhanced modules and corner assemblies enable the DualMove to handle a variety of product sizes and weights at high speeds.

Key features of the DualMove™ Pallet System:

- Dual T10 timing belt conveyors with steel cords, available in low friction, medium friction, and static conductive options

- Quick belt change without removing the conveyor

- Static conductive pallet skirts

- Simple and cost-effective pin tracking system

- Supports 30-100 lbs per pallet, with speeds up to 215 fpm

- Energy-efficient 24V DC motors on all modules

ERT150

The ERT®150 is perfect for assembly automation, inspection, and packaging for delicate, light-load applications, including pharmaceuticals, medical devices, and electronics. Its belt-free design prevents particle accumulation caused by belt friction and can be configured without pneumatics to meet cleanroom standards. The ERT150 seamlessly integrates with robotics and automated vision systems, enhancing its versatility and automation capabilities.

Key Features of the ERT150:

- Custom zoning for low to no back pressure accumulation

- Easy maintenance: no belting, and individual rollers are easily replaced without affecting the rest of the system

- Loads up to 35 lbs per pallet

- Low voltage brushless DC motors for energy-efficient operation

- Static conductive HPDE pallet skirts

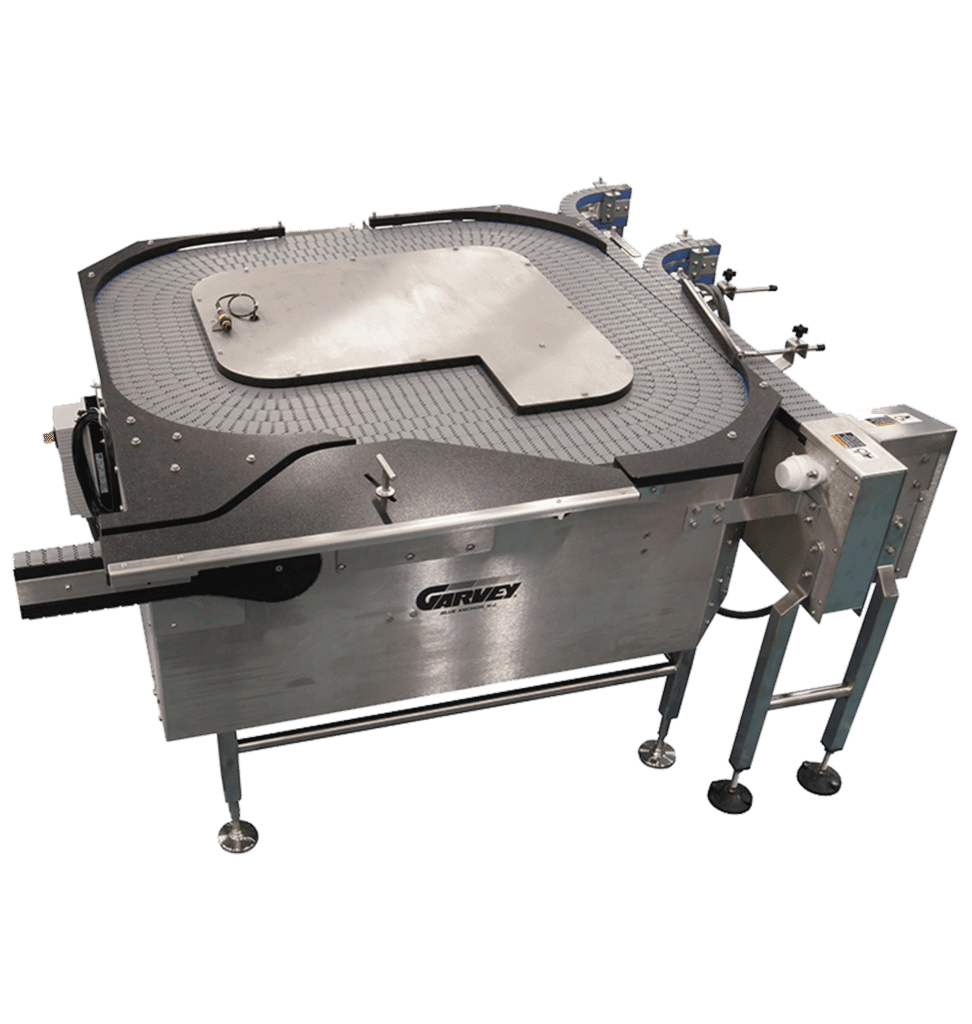

Infinity RX Rotary

Garvey’s Infinity RX rotary accumulation table, equipped with patented technology, rapidly accumulates and sorts unstable products, making it perfect for pharmaceuticals, vials, and other delicate medical items. This table can be configured for single or multi-lane accumulation, boosting line efficiency and throughput for large and small pharmaceutical applications.

Key Features of the Infinity RX

- Zero-pressure accumulation

- On-demand flow divide

- Minimized energy usage, with reduced friction and noise production

- Small-footprint accumulation

- Single filing outfeed with adjustable widths for a range of product sizes

Visit Garvey’s website to learn more about the Infinity RX

montrac® Monorail Shuttle System

montratec will also be showcasing the innovative montrac® monorail shuttle conveyor. Specializing in advanced shuttle conveyor systems, montratec designed the montrac® systems to optimize material flow and enhances automation processes. The montrac® features an efficient, low-profile design capable of transporting products at high speeds through various production stages and even across multiple facility floors. The shuttles are individually driven and can be custom-programmed, making running multiple production stages on one line easy.

Key benefits of the montrac® system:

- Modular Design: Easy installation, customization, and expansion to meet evolving needs

- Versatility: Suitable for a wide range of industries and applications, from EV assembly lines to distribution centers

- Efficiency: Quick-change components and intelligent control systems maximize efficiency and minimize downtime

- Reliability: Built to high-quality standards, ensuring continuous operation even in demanding environments

Learn about the montrac® system

Lifting Solutions

Alongside the material handling solutions from CMCO’s Conveyance Group, our Battery Show booth will also feature an innovative lifting solution from Unified and CM.

Unified Lift Assist

Unified’s ergonomic Lift Assist is a manual lifting system that provides smooth transport and positioning of bulky or heavy objects while taking the strain off assembly technicians. Delicate parts, such as EV battery components, are lifted easily from a staging area to be installed into a larger cell assembly while reducing the risk of static buildup or damage to the outer casing and electronic components.

Lift Assist Options

- Articulating arms are ideal for complex movements within a workspace

- Reach up to 10 ft

- Lifting capacity up to 500 lbs

- Balancer module for precise parts placement

- Lifting capacity up to 485 lbs

- Ceiling rail-mounted vertical lifters for heavy loads and movement across workstations

- Lifting capacity up to 1000 lbs

- Torque up to 760 ft/lbs

- Multiple handling options, including grabbers/clamping arms, vacuum or suction cups, hooks, and magnets

Explore Unified’s Lifting Solutions

CM BatteryStar Hoist

The Battery Star from CM is a powered chain hoist designed for portability and ease of installation. Built with technology from CMCO and Milwaukee Tool® this hoist offers heavy-duty lifting capabilities and is compatible with the same M18™ batteries already on your job site.

BatteryStar Specifications

- Capacity: 1 metric ton

- Lift: 20 ft. standard. Optional lifts to 60 ft

- Lift Speed: 8 feet per minute

Learn more about the new BatteryStar

Visit the CMCO Conveyance Group Booth at the Battery Show

Battery Show North America will be held on October 8-10 in Detroit, MI. It will be an exciting show with innovative solutions from across the battery and electronics industry. Stop by Booth 307 to see Dorner’s pallet conveyor systems and explore the newest material handling technology from CMCO’s Conveyance Group.