In modern manufacturing, maximizing production efficiency while minimizing downtime is crucial for maintaining a competitive advantage and meeting customer demand.… Read more »

Category: Conveyor Automation

Maximizing Productivity with Automated Conveyor Systems in Warehousing

The landscape of modern warehousing has undergone a remarkable transformation since the first conveyor belt systems revolutionized material handling operations… Read more »

What are you really getting with an AGV?

In the world of automated guided vehicles (AGV) and montrac® shuttle conveyors, there are several misconceptions to be addressed. Let’s… Read more »

Choosing the Right Dorner Pallet System: A Comprehensive Comparison

Dorner’s ability to create the perfect solution for almost any application has been the defining factor that positioned us as… Read more »

3 Predictions for Upcoming Changes in The Conveyor Industry

The conveyor industry has been a cornerstone of modern manufacturing and material handling for decades, revolutionizing production lines and streamlining… Read more »

Dorner Conveyors Help to Solve Pharmaceutical Industry Challenges

The pharmaceutical industry constantly evolves to meet new demands and patient needs while striving to operate as safely and efficiently… Read more »

See Dorner’s E-Commerce Conveyors in Action

The e-commerce market is fast-paced and continuously growing in demand. At Dorner, we understand the importance of ensuring the… Read more »

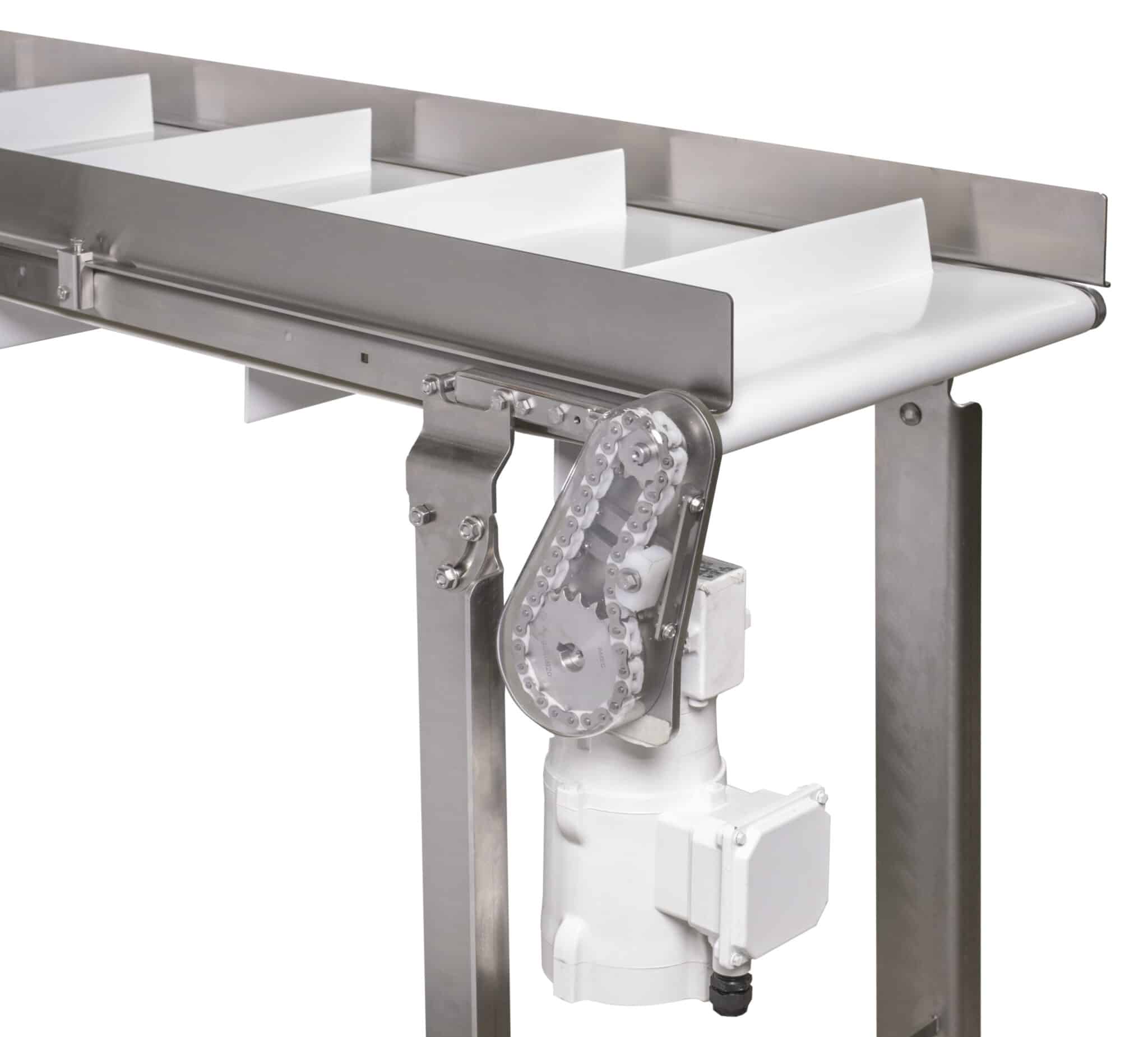

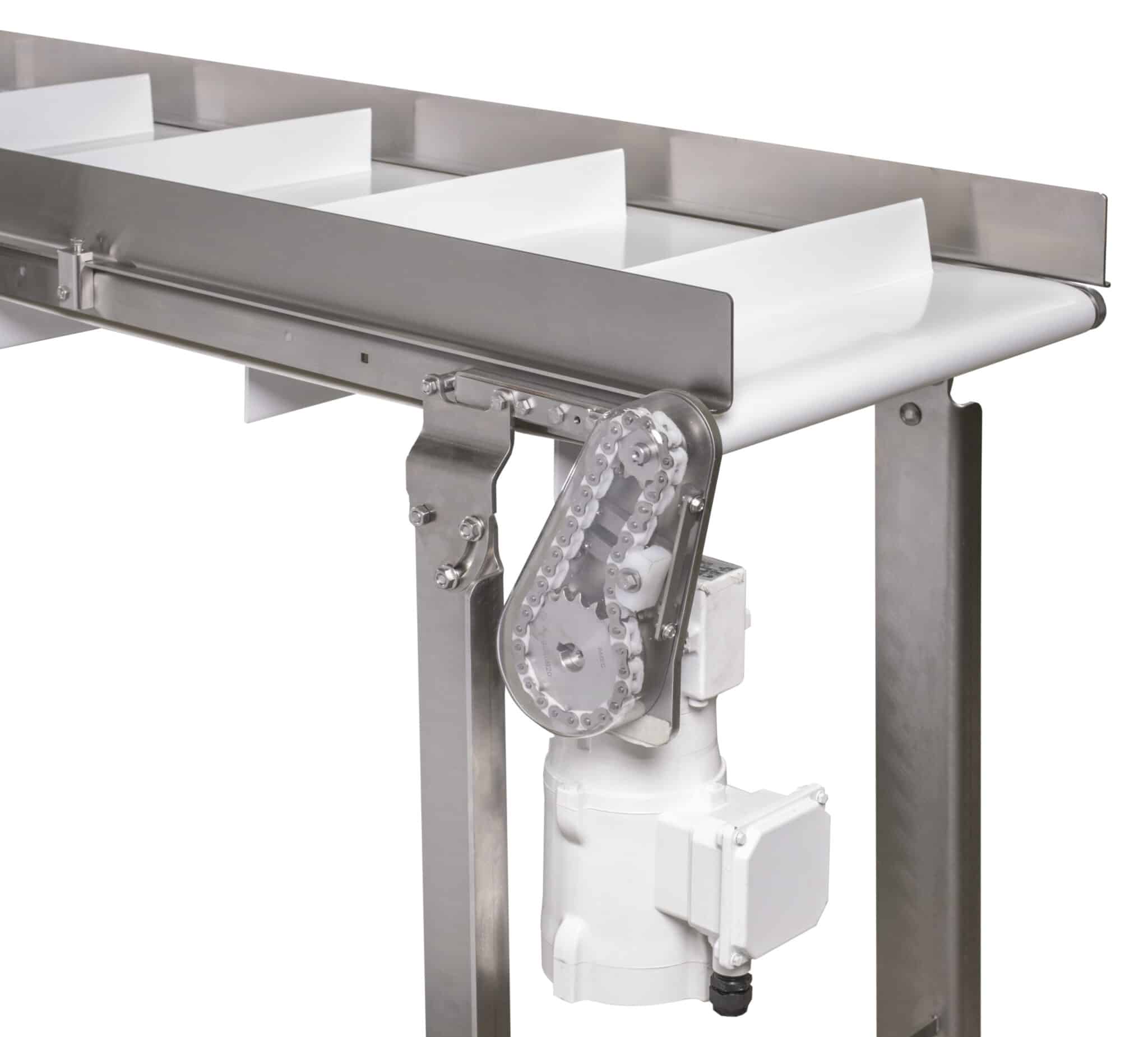

Introducing the AquaGard LP, Dorner Europe’s New Low Profile Sanitary Conveyor

The NEW AquaGard LP Conveyor Dorner Europe’s new AquaGard LP conveyor is designed to fit in tight spaces, making… Read more »

Custom Conveyor Systems for Life Science Applications

During the peak of the COVID-19 pandemic, automation proved to be an essential aspect of manufacturing. Many companies were… Read more »

Increasing Efficiency with Warehouse Automation

One of the biggest challenges for businesses across industries is managing their warehouse and material handling processes efficiently and accurately.… Read more »

Pros and Cons of Integrating Robotics in Manufacturing

As technology continues to progress towards new innovations in automation, it is no surprise that the robotics industry is… Read more »

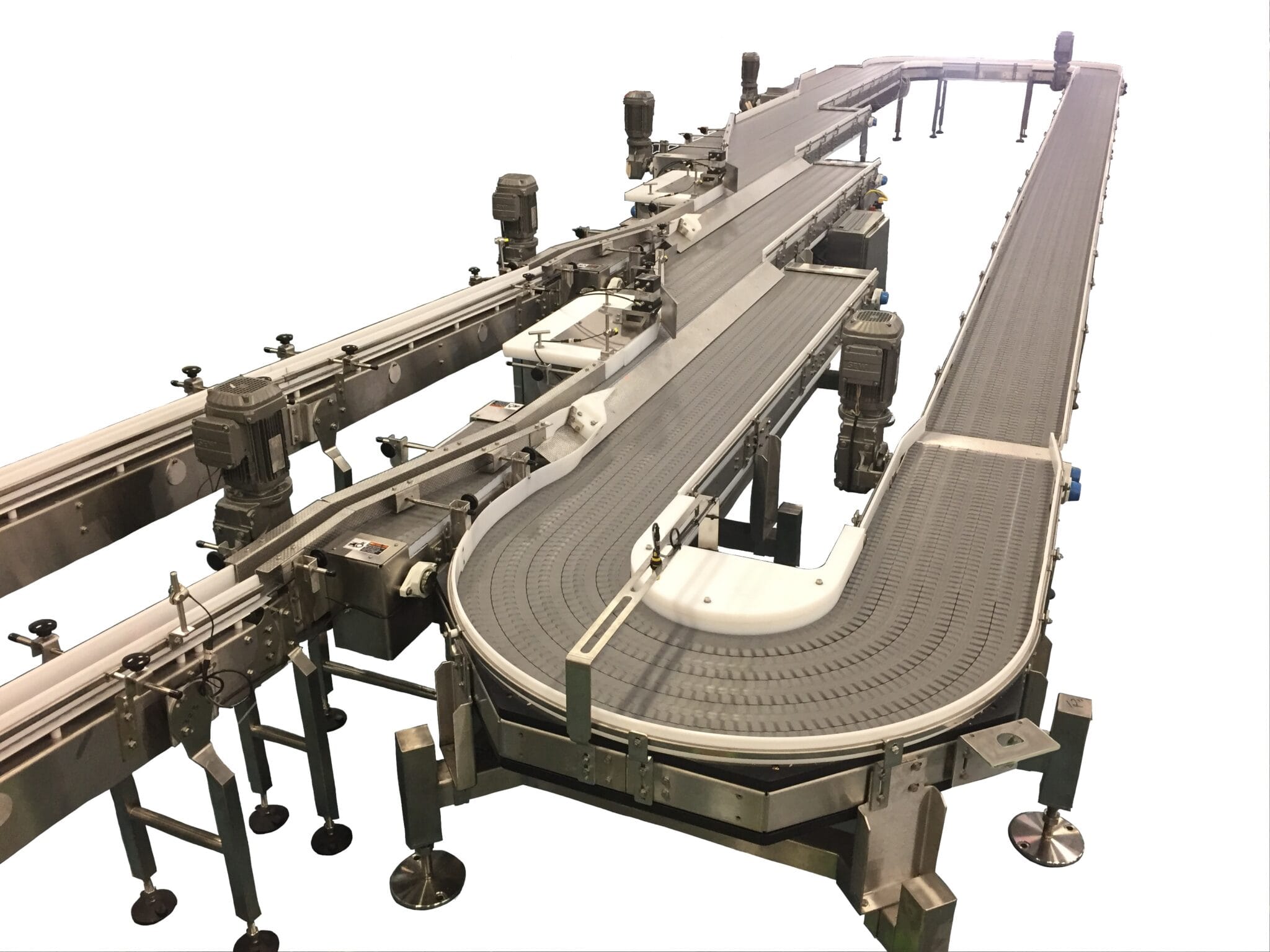

Pair Dorner Conveyors with Garvey Accumulators

Dorner partners with many organizations to bring top-of-the-line conveyance products and systems to our customers. In this new series,… Read more »

Introducing the AquaGard LP, Dorner’s New Low Profile Sanitary Conveyor

The NEW AquaGard LP Conveyor Dorner’s new AquaGard LP conveyor is designed to fit in tight spaces, making it… Read more »

QuickChat: ERT Conveyance Technology

Machine Design Features Dorner: Quick Chat Series While Dorner’s wide variety of industrial, precision and sanitary conveyance solutions are popular,… Read more »

Next Evolution of Dorner’s Edge Roller Technology Conveyor, the ERT150

The next evolution in Dorner’s Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly… Read more »

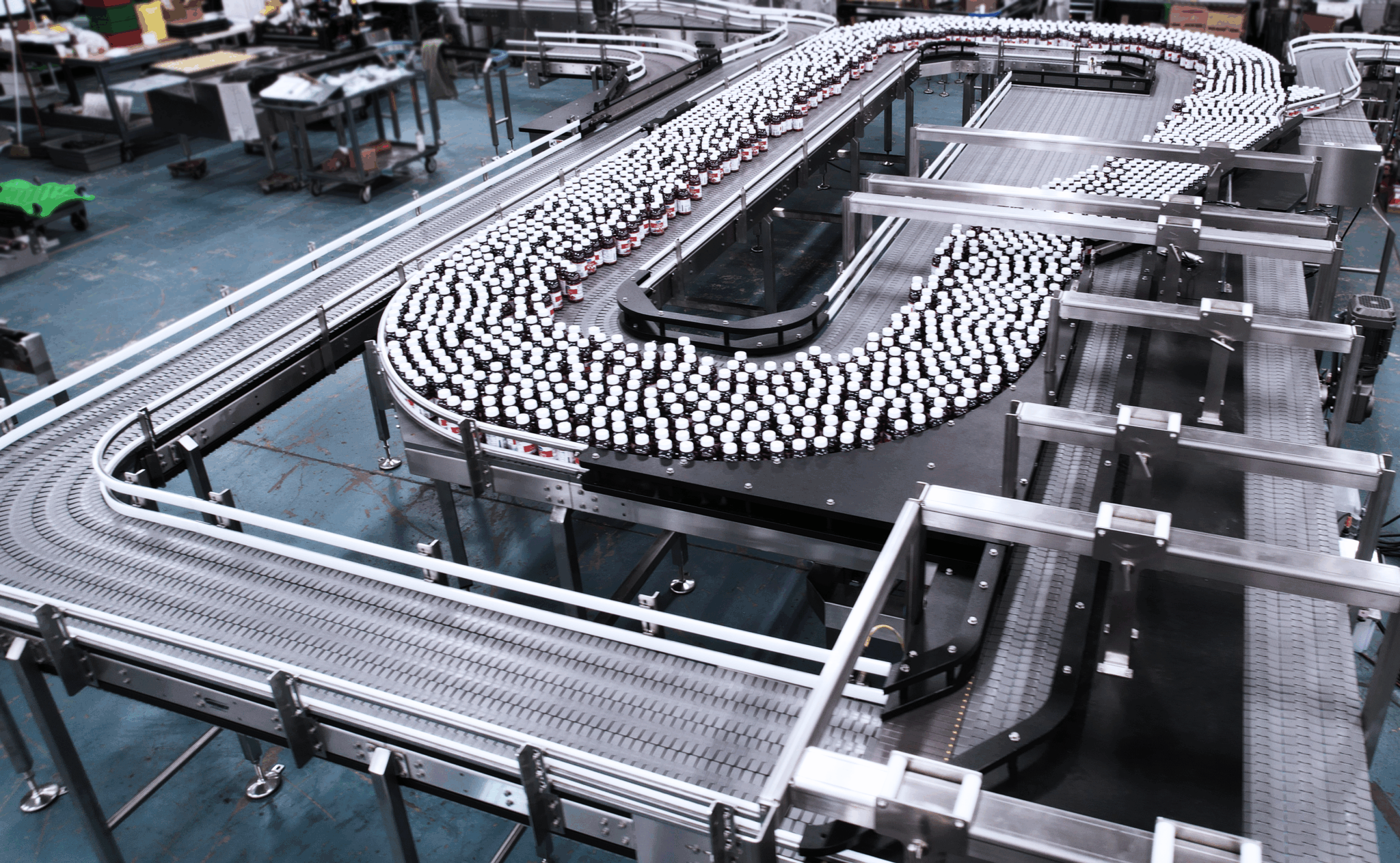

Dorner Engineered Solution – Recirculating Conveyors

Manufacturing lines require mechanical solutions to facilitate the consistent flow products to maximize throughput, and recirculating conveyors are a… Read more »

Next Evolution of Dorner’s Edge Roller Technology Conveyor, the ERT150

The next evolution in Dorner’s Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly… Read more »

Create Zones for Better Control

As automation becomes more integrated into medium- and heavy-load accumulation and assembly applications, the need for conveyors with zoning… Read more »

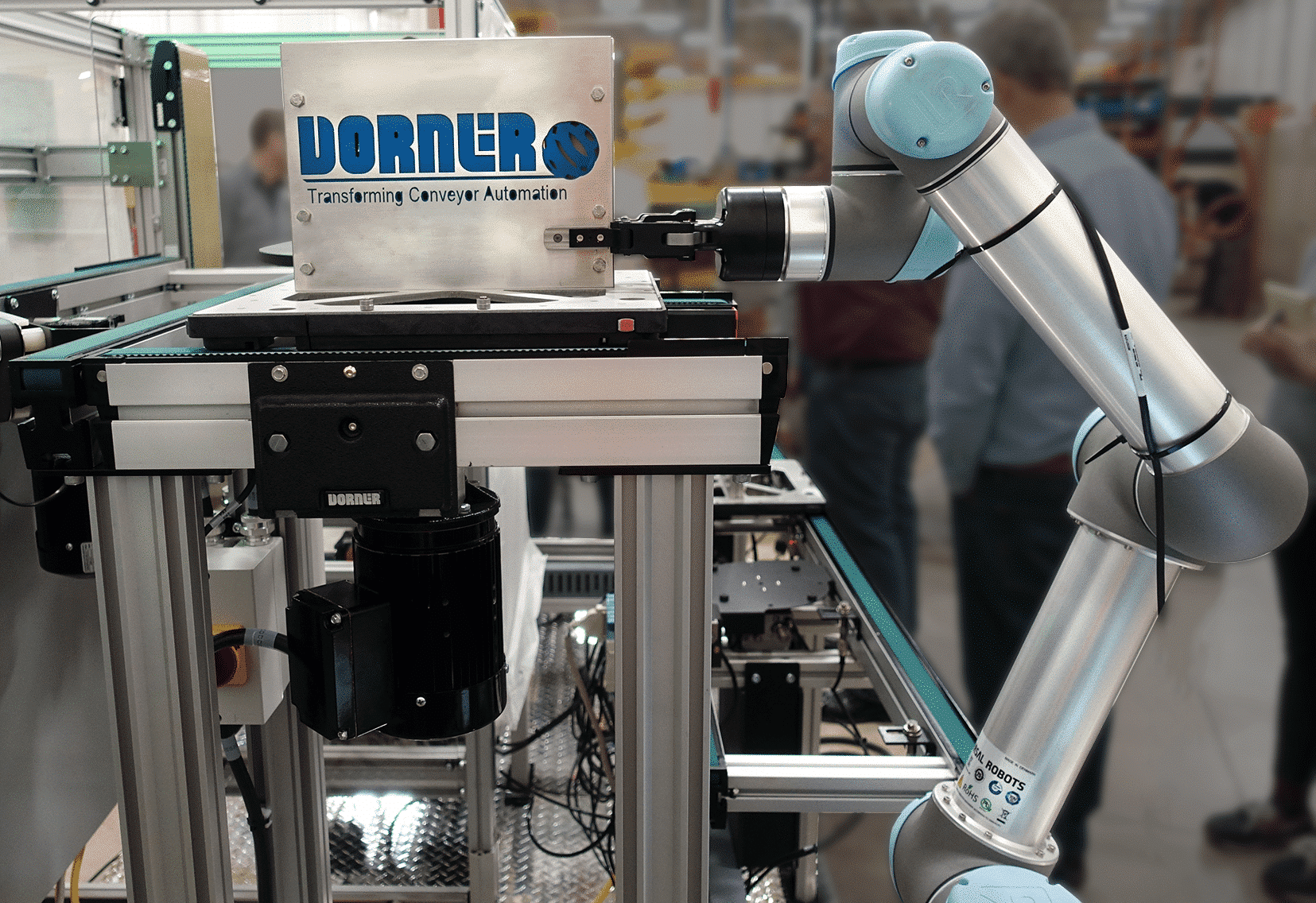

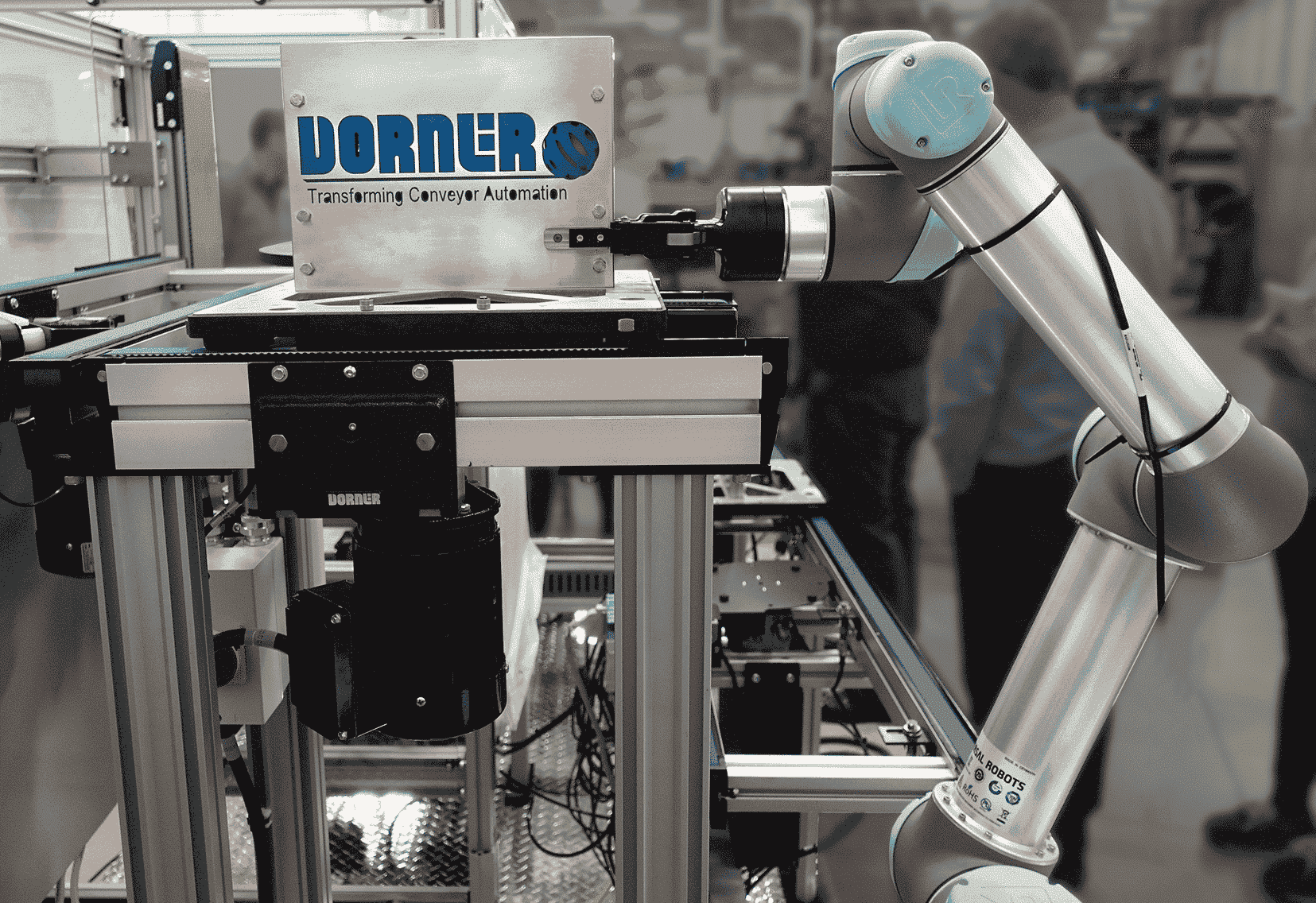

How to Amplify Your Conveyor System with Robotics

This article originally appeared in the May 2021 version of Design World. The integration between conveyors and robotics has… Read more »

Improve Production Line Efficiency with Industrial and Automation Conveyors

Industrial and automation conveyors are a crucial part of any production facility. They move parts and product from one… Read more »

Conveyors Are Fulfilling Key Roles in E-Commerce Applications

When it comes to both conveyors and online orders, quick delivery is king. Nowhere is that more prevalent than over… Read more »

How to Integrate Robotics & Conveyors Easily

The integration between robotics and conveyors in recent years has brought a much higher level of automation to a… Read more »

Add Simple Automation with Retractable Conveyors

A retractable conveyor, or retracting tail, is a conveyor frame with the ability to retract or extend, typically on… Read more »