In the world of automated guided vehicles (AGV) and montrac® shuttle conveyors, there are several misconceptions to be addressed. Let’s take a closer look at some common misconceptions and compare the two systems to gain a better understanding of their capabilities.

Misconception 1: AGV Fleet can run 24/7

Reality with AGVs: While AGVs can run 24/7, the cost of purchasing, charging, and maintaining an AGV is substantial.

Benefit of montrac®: Downtime concerns are real with AGVs. Replacing an AGV can be costly and time-consuming. In contrast, montrac® shuttles are readily available and more cost-effective leading to a greater certainty of production capabilities.

Misconception 2: AGV can be used in building a flexible and space-saving production

Reality with AGVs: Flexibility comes at a cost in AGV units, and longer routes for AGVs may require additional units or transfer stations to maintain desired processing times.

Benefit of montrac®: Route determinations for AGVs require more space and limit the actual usable space. Montrac, on the other hand, offers a space-efficient solution with the ability to extend loops at any time and utilize a range of shuttle sizes on one line.

Misconception 3: Cycle Time can be maintained by adjusting speed and quantity of AGV

Reality with AGVs: Adjusting AGV cycle time can lead to potential traffic jams and may not guarantee the desired cycle time.

Benefit of montrac®: Montrac® provides the ability to implement buffer zones on the route, ensuring the desired cycle time requirement is met without resulting in downtime.

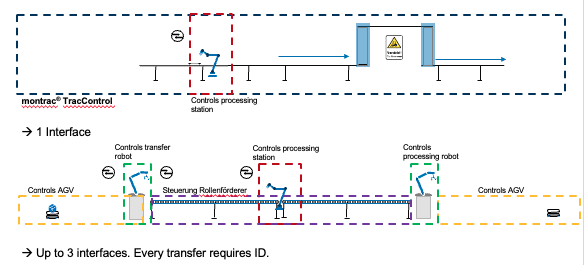

Misconception 4: AGV Controls are easy to implement into existing systems

Reality with AGVs: AGVs require multiple interfaces to work in conjunction with different control systems, leading to higher maintenance costs.

Benefit of montrac®: montrac shuttles run on one control system and integrate with its own transfer system, eliminating the need for multiple interfaces.

Misconception 5: The Positioning Accuracy of the AGV is Good Enough

Reality with AGVs: AGV positioning accuracy may not always meet the high precision requirements for implementing workpieces.

Benefit of montrac®: montratec’s positioning accuracy is significantly higher, allowing for precise work on the shuttle without the need for workpiece removal.

Misconception 6: Workpiece can be worked on the AGV

Reality with AGVs: Manual processing on an AGV may require additional construction and can lead to increased battery consumption and reduced range.

Benefit of montrac®: montratec’s Positioning Unit ensures secure processing at an ergonomic working height on the Trac, providing easy, ergonomic, and secure implementation of manual workstations.

Final Considerations

While AGVs have their advantages, it’s essential to address the misconceptions and consider the benefits offered by montratec, such as cost-effectiveness, space efficiency, precise positioning, and secure processing capabilities. Making an informed decision based on these considerations can lead to optimized automated material handling solutions.