The pharmaceutical industry constantly evolves to meet new demands and patient needs while striving to operate as safely and efficiently as possible. However, pharmaceutical manufacturing and distribution have fundamentally changed with recent challenges posed by supply chain issues, changes in demand, and COVID-19.

PMMI has published a report on the shift the pharmaceutical industry is experiencing and how industry partners can make changes to meet these needs as they fluctuate and change. In particular, the e-commerce pharmaceuticals and mail-order prescriptions boom have spurred a greater need for increased automation tools, efficient packaging lines, robotics, and AI to improve accuracy and quality.

How can automation improve pharmaceutical production?

Technological improvements and significantly increased demand for pharmaceuticals have necessitated automated processes within pharmaceutical manufacturing and packaging. Implementing automated material handling, inspection, and packaging allows manufacturers to increase production speed and efficiency. Utilizing intelligent motion technology throughout a manufacturing line also transfers repetitive or strenuous tasks from staff to the conveyor system, giving employees more time to focus on more complex tasks.

Not only do automation capabilities increase efficiency, but they also help to improve accuracy and quality. Human error is one of the leading causes of manufacturing mistakes that lead to product loss or defects. In the pharmaceutical industry, a product defect or accidental mix-up can be highly costly for the manufacturer and even life-threatening for consumers.

With the advanced conveyance capabilities of Dorner’s belted and pallet conveyor systems, pharmaceutical companies can precisely control product movement throughout the production line without manual intervention, allowing them to maintain the highest quality and accuracy. Our pharmaceutical conveyors can be seamlessly integrated with photo eyes and other sensors to track products, inspect for quality, and control flow for optimal production rates.

How will changes in pharmaceutical demand affect manufacturing equipment?

In recent years, PMMI has reported increased demand for injectable pharmaceuticals, putting more pressure on pharmaceutical companies to produce a broader range of products to meet consumer needs. Additionally, the higher rate of injectables and companies producing different effects on the same manufacturing line pose a greater risk for contamination.

We are seeing a greater need for flexible equipment that can adapt to run a range of product sizes and materials while also easy to sanitize and change over for different product lines. Moreover, manufacturing pharmaceuticals requires machinery that does not produce particulate matter or contribute to airborne contamination. OEMs and equipment suppliers must carefully design pharmaceutical processing machinery to meet these stringent sanitary requirements.

Conveyors are the foundation of any automated pharmaceutical production line, so they must be adaptable to different product sizes, materials, and production and sanitary needs. Whether manufacturers utilize traditional hygienic practices with water or chemical washdowns or process pharmaceuticals in cleanroom environments, Dorner has the ideal conveyor solution.

FlexMove Plastic Chain Conveyors – Flexible Filling, Indexing, & Sorting

Our FlexMove conveyor series is the ultimate solution for flexible material handling in prescription fulfillment and pharmaceutical packaging. With the industry’s most flexible plastic chain belt and a large selection of modules to customize your system, FlexMove conveyors are easily adaptable to almost any product line.

Features of FlexMove Pharmaceutical Conveyors

- Ideally suited for tight spaces, elevation changes, and long lengths

- Powered transfers for smooth end transfers of product as small as 3 inches

- Numerous belt and module options for added customization

- Sleek, compact design maximizes horizontal and vertical space of facility

Learn more about Dorner’s Flexmove Series

ERT150 – Pallet Conveyors for Injectable Pharmaceuticals

Dorner’s Edge Roller Technology (ERT) conveyors are uniquely engineered with short rollers on the edge of the conveyor frame to create an open-frame design, eliminating the risk of jams and product damage. Products are carried on static conductive pallets and precisely positioned products for the highest accuracy and safety during production. By eliminating the belt, this conveyor drastically reduces the risk of particle buildup caused by friction and wear that would show in a traditional belted conveyor.

The ERT150 lends itself perfectly to vial filling and injectable pharmaceutical processing. With customizable pallets and an advanced, patent-pending gearbox that makes reconfiguring the field a breeze, this conveyor can be easily designed and integrated into many pharmaceutical production and packaging applications.

Read about the ERT150’s Clean Design

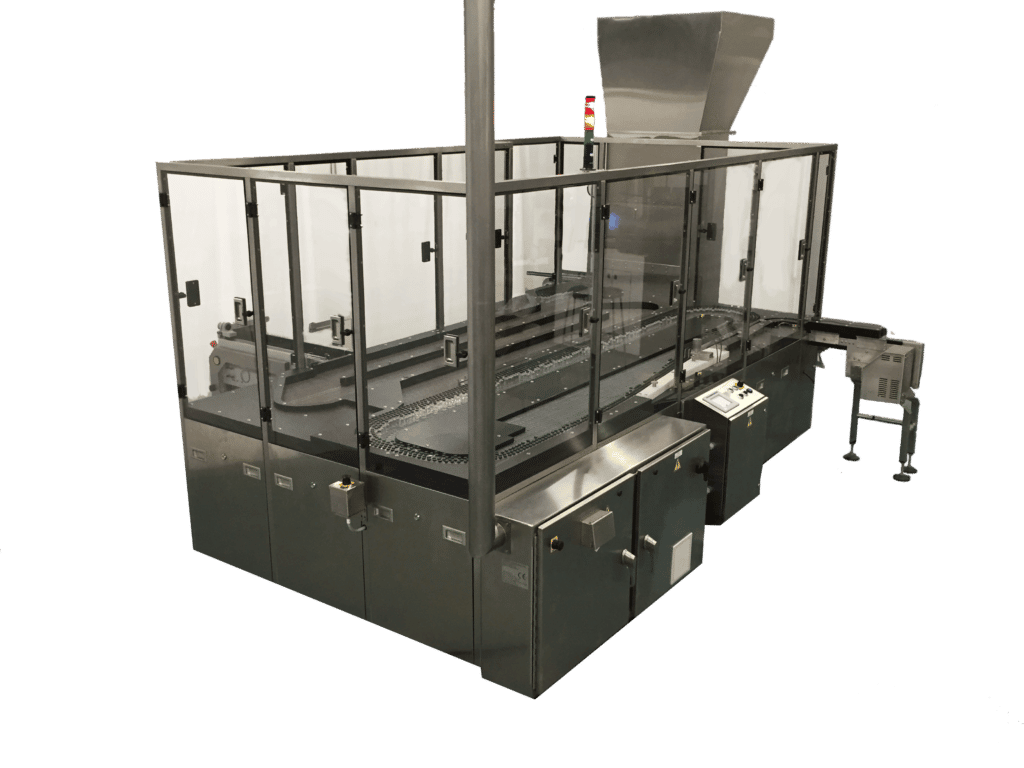

Garvey’s Automatic Vial Dryer – Vial Accumulation & Drying

In injectable and liquid pharmaceutical production, many products are temperature sensitive and must be kept in a highly controlled environment throughout production and storage. However, there are stages in processing and packaging that cannot be as easily temperature-controlled, and often products spend 24-48 hours out of the cold chain during the packaging process. While these processes are necessary for packaging, they greatly risk a reduction in the potency and efficacy of vital medications.

Garvey has developed an innovative system that cuts the time products are out of the cold chain to as little as 5 minutes. With a patented pressureless loop and high-volume laminar flow accumulator, vials can be dried and single-filed to an inspection machine or labeler at up to 900 vials per minute! The modular design of Garvey’s vial dryer also makes it highly adaptable and customizable to a manufacturer’s unique processing needs.

Explore Garvey’s Pharmaceutical Solutions

AquaGard LP – Sanitary Packaging Conveyors

Finally, Dorner’s AquaGard LP is a sanitary stainless-steel conveyor designed for clean packaging operations. With a tip-up-tail roller design and stainless-steel frame, this conveyor system is quick and easy to clean, allowing for line changeovers as short as 5 minutes. Additionally, the low-profile design that Dorner’s conveyors are known for makes the AquaGard LP an ideal solution for integrating with other equipment such as inspection machines, automated packaging, and robotics.

Features of AquaGard LP Conveyors

- Quick five-minute belt change for increased uptime

- Compact and enclosed tensioning system providing smooth and snag-free cleaning

- V-groove frame with a guided belt for accurate tracking

- Low-profile, operator-safe design with no pinch points

Learn more about the AquaGard LP

Turnkey Conveyor Solutions

With quickly shifting consumer demands and production space becoming more limited, modern pharmaceutical producers face the challenge of maintaining production for numerous product lines while keeping their facilities streamlined and efficient. This significantly strains equipment and machinery to run different product types and sizes while also being cleaned between each product line.

Conveyor experts at Dorner take the time to get to know you and your business to understand the unique needs of your production line. Our custom solutions offer pharmaceutical producers turnkey conveyance solutions that have the flexibility needed for multiple product types while being adaptable for the future.

Custom Solutions for the Pharmaceutical Industry

At Dorner, we understand how important it is for pharmaceutical manufacturing and packaging partners to adapt their products to meet customer needs. Our engineering, fabrication, and assembly teams are constantly working to develop new products and custom solutions for pharmaceutical companies to solve conveyance and packaging issues and create a more efficient, streamlined process.

The Dorner team can create complete conveyance systems or standalone conveyor elements to integrate into any pharmaceutical packaging process seamlessly. With our high-quality standards and skilled team, you can be sure that every conveyor we provide is stringently tested and built to meet your company’s exact needs.