Product damage during conveyor transfers is a significant concern for manufacturers, as it directly impacts bottom-line profitability through waste, rework, and customer dissatisfaction. So, how can we reduce product damage during conveyor transfers?

The most effective ways to reduce product damage during transfers are maintaining proper belt speeds (typically slower for delicate or unstable products), minimizing transfer gaps (keeping them under the product length), and using appropriate guide rails to control product movement.

While these core principles are universal, the specific approach you’ll need depends heavily on your product type, conveyor configuration, and production speed requirements. Discover how to optimize transfer points for your specific situation and learn about advanced solutions for complex transfer scenarios.

Understanding Why Products Get Damaged During Transfers

Product damage doesn’t happen randomly, it occurs at predictable points where physical forces exceed a product’s tolerance limits. The most common damage occurs at transfer points and accumulation zones, where products experience sudden changes in velocity, direction, or support conditions.

The Physics of Product Damage

When products move through conveyor systems, they encounter various forces that can cause damage:

- Impact forces occur when products drop onto surfaces or collide with other items. Even a small drop of 2-3 inches can generate forces equivalent to several times the product’s weight, potentially causing internal damage to electronics or cracking in fragile items.

- Compression forces build up in accumulation zones where products come into contact with each other. This is particularly problematic for packaged goods, where excessive pressure can deform packaging or damage contents.

- Friction forces from rough surfaces or misaligned guides can scratch finishes, tear labels, or create heat that affects temperature-sensitive products.

- Acceleration forces from sudden starts and stops can cause products to shift, tip, or slide, leading to surface damage or complete product failure.

Critical Damage Points in Conveyor Systems

Understanding where damage typically occurs helps focus prevention efforts:

- Transfer zones between conveyors are the highest-risk areas. Sudden changes in speed, direction, or support create opportunities for product impacts and misalignment.

- Elevation changes subject products to gravitational forces that can cause sliding or tipping

- Accumulation areas can create compression forces as products back up during line stops or slowdowns.

- At high speeds, curve sections generate lateral forces that can cause products to shift or collide with guides.

Creating Smooth Transfer Conditions

The foundation of damage prevention lies in creating conditions where products experience minimal physical stress during movement between conveyor sections.

Eliminating Sharp Transitions

Traditional conveyor designs often feature larger rollers, creating wide gaps at transfer points, which can misalign or drop product. Modern transfer systems utilize small-diameter rollers and offer added nose bar transfers, allowing for small or unstable products to smoothly transfer from one conveyor to another without jostling or shock.

Key benefits of smooth transitions:

- Reduce impact forces by distributing the transfer load over time

- Maintain product momentum while gradually adjusting to new conveyor conditions

- Prevent sudden jolts that can damage internal components

- Create highway-like merging conditions for seamless product flow

Controlling Acceleration and Deceleration

Gradual speed changes prevent products from experiencing sudden forces that can cause damage. This is particularly important for loose items, liquids, or products with moving parts that can shift during transport.

Advanced drive system features:

- Integrated controls solutions offer programmable acceleration curves customized for different product types

- Slower acceleration for light items to prevent sliding

- Gentle speed changes for delicate products

- Consistent velocity maintenance throughout the system

Matching Conveyor Speeds

Speed mismatches between adjacent conveyors create impact conditions as products transfer from one section to another. Even small differences can generate significant forces when products repeatedly experience these transitions.

Speed matching requirements:

- Consistent momentum maintenance throughout the system

- Reduced stress on both products and equipment

- Careful system design and regular calibration

- Optimal performance through precise speed control

Dorner’s 2200 Series conveyors feature advanced drive systems that allow for precise speed matching and programmable acceleration curves, making them ideal for applications where gentle product handling is critical. For heavier loads requiring similar precision, 3200 Series heavy-duty conveyors provide the same smooth operation capabilities with increased load capacity.

Selecting Belt Materials That Protect Products

The belt surface is often the only thing separating your products from potential damage, making material selection crucial for damage prevention.

Understanding Surface Interactions

Different products interact with belt surfaces in unique ways. Smooth, light-weight products such as bottles or plastic parts slide easily across most surfaces, while heavy, textured items may catch on rough belts.

Surface type considerations:

- Smooth surfaces work best for most applications because they minimize friction and reduce the likelihood of product catching or snagging, while also being easy to clean for sanitary applications.

- Textured surfaces provide better traction for inclined transport or in applications where it is crucial for product to remain in place on the belt. However, they should not be used for accumulation, as the added friction can scuff product surfaces, cause excessive heat, and quickly wear out the belt and drive components.

- Low-friction materials facilitate easy product release during transfers and offer a smooth surface for low back-pressure accumulation.

Material Properties for Damage Prevention

Different belt materials offer varying levels of protection:

- Polyurethane provides excellent wear resistance and flexibility, making it ideal for applications where products need to slide smoothly across the belt surface

- Silicone offers high-temperature resistance while maintaining a smooth surface that won’t mark or scratch products

- FDA-approved materials ensure food products aren’t contaminated during transport while providing the smooth surfaces necessary for damage prevention

For food processing applications requiring the highest sanitary standards, AquaGard and AquaPruf sanitary conveyors feature FDA-approved belting materials combined with stainless steel construction for optimal product protection and contamination prevention.

Preventing Belt-Related Damage

Belt wear and deterioration can create conditions that damage products:

Common belt-related issues:

- Frayed edges that can snag products or produce debris that contaminate delicate products

- Worn spots that create rough surfaces and wear on drive mechanisms

- Foreign material buildup that affects product flow

- Stretching increases belt sway and can lead to product misalignment

Prevention strategies:

- Regular inspection and maintenance schedules

- Proper belt tensioning to prevent premature wear

- Appropriate cleaning procedures to maintain surface quality

Implementing Effective Product Containment

Proper containment prevents products from moving laterally or becoming misaligned during transport, reducing the likelihood of collisions and damage.

Guiding Without Constraining

Effective side guides provide gentle boundaries that redirect or reorient products without applying excessive pressure. The key is creating guides that redirect products smoothly rather than creating hard stops that generate impact forces.

Effective guide design features:

- Adjustable positioning allows guides to accommodate different product sizes without over-constraining items

- Smooth, rounded surfaces and curved ends prevent products from catching on guide edges

- Low-friction materials ensure products slide smoothly along guides rather than binding or catching

Preventing Collision Damage

Products can also damage each other during transport, particularly in accumulation zones or when different-sized items are processed together.

Collision prevention strategies:

- Consistent spacing between products prevents collisions during normal operation

- Proper timing control reduces the impact of emergency stops

- Size-appropriate containment ensures guides are positioned correctly for the products being handled

- Accumulation zones designed for the production flow prevent product backup and pressure buildup

For applications requiring precise product positioning to prevent collisions, precision move conveyors offer positioning accuracy within ±0.02 inches, ensuring consistent spacing and alignment throughout automated processes.

Managing Accumulation to Prevent Damage

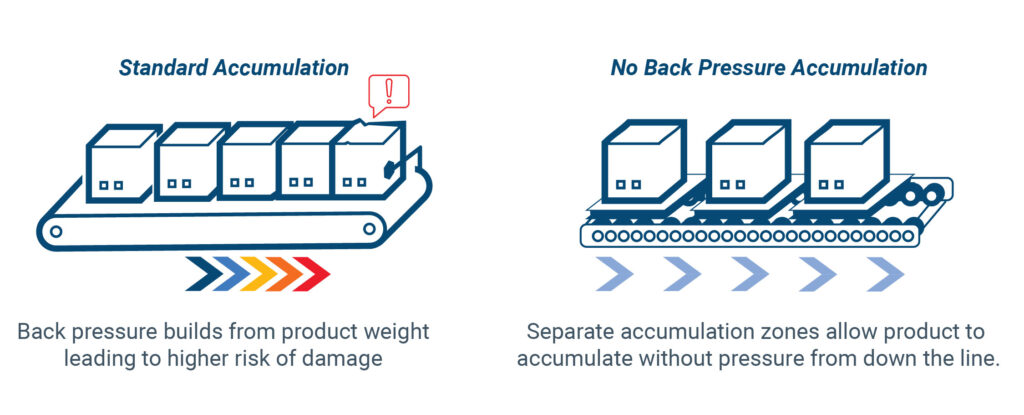

Accumulation zones are necessary for managing production flow variations, but improperly designed zones can create conditions where products experience damaging forces.

Understanding Accumulation Forces

Traditional conveyor accumulation provides a length of conveyor products where can back up, allowing for extra time between steps in production or to reduce downtime when there is a delay upstream. Here, a guide or blocking arm keeps products from moving past a certain point on the conveyor, while the conveyor continues to move, allowing for additional products to accumulate. This causes products to exert forces on each other that can cause damage. A line of 20 products can generate significant pressure on the first item, potentially causing crushing or deformation.

Types of accumulation forces:

- Back-pressure builds as products push against each other during line stops

- Release forces occur when accumulated products suddenly begin moving again

- Compression forces can crush packaging or damage fragile items

- Surge forces may cause impacts when products restart movement

Zero-Pressure Accumulation Principles

Zero-pressure systems eliminate damaging forces by preventing products from pushing against each other:

Key system features:

- Independent zone control ensures each section operates based on its own product detection

- Smooth acceleration when restarting prevents products from surging forward

- Consistent spacing maintains safe distances between products throughout the accumulation process

- Force elimination prevents the buildup of damaging back-pressure

Accumulation Zone Design

Proper accumulation zone design considers product characteristics and system requirements:

Design considerations:

- Zone length should match product dimensions for effective control

- Sensor positioning must accurately detect products while avoiding false triggers

- Speed control should provide gentle acceleration and deceleration

- Capacity planning ensures adequate space for expected accumulation volumes

HighVolume Accumulation Solutions

For complex or high-volume accumulation requirements, Garvey’s innovative accumulation systems are custom-engineered to handle specific product characteristics and flow patterns while minimizing damage risk.

Accumulation System Features

- Accumulates a large number of products in a relatively small footprint

- Continuous motion belts recirculate products and prevent back-pressure

- Custom guiding automatically positions, lanes, or distributes product, offering a smooth transition to the next process

- Evenly distributes products to machinery or operators downstream, while maintaining a consistent production flow upstream.

Monitoring and Continuous Improvement

Effective damage prevention requires ongoing monitoring and adjustment to maintain optimal performance.

Establishing Baseline Measurements

Before implementing damage prevention strategies, establish baseline measurements of current performance:

Key metrics to track:

- Damage rate tracking including both frequency and severity of incidents

- Location analysis to identify specific areas where damage occurs most frequently

- Cost analysis quantifying financial impact including direct and indirect costs

- Pattern identification to understand when and why damage occurs

Implementing Monitoring Systems

Continuous monitoring helps identify problems before they cause significant damage:

Monitoring approaches:

- Visual inspection at key points can catch developing problems early

- Sensor monitoring of belt alignment, speed variations, and system performance

- Product feedback from downstream processes or operators

- Data collection for trend analysis and problem identification

Making Data-Driven Improvements

Regular analysis of damage data helps identify improvement opportunities:

Analysis methods:

- Pattern recognition may reveal correlations between damage and specific conditions

- Root cause analysis helps identify underlying causes rather than just symptoms

- Preventive measures can be implemented based on data analysis

- Performance tracking ensures improvements are sustained over time

Cost-Benefit Analysis of Damage Prevention

Implementing damage prevention measures requires investment, but the returns typically justify the costs through reduced losses and improved efficiency.

Calculating Current Damage Costs

Many organizations underestimate the true cost of product damage. A comprehensive analysis should include:

Direct costs:

- Product replacement costs for damaged items

- Labor costs for handling damaged products

- Rework expenses for repairable items

- Disposal costs for unusable products

Indirect costs:

- Customer relationship costs from complaints and returns

- Opportunity costs from production delays

- Reduced efficiency from system problems

- Potential lost business from quality issues

Evaluating Prevention Investment

Damage prevention investments should be evaluated based on their potential to reduce total damage costs:

Investment categories:

- Equipment costs for improved conveyor systems and materials

- Installation costs including downtime for system modifications

- Training costs for operators and maintenance personnel

- Ongoing costs for maintenance and system optimization

Return on Investment Timeline

Most damage prevention investments pay for themselves within 1-3 years:

Factors affecting ROI:

- Current damage rates and associated costs

- Product values and replacement costs

- Scope of improvements implemented

- Operational efficiency gains from better systems

Prevent Damage and Reduce Costs with Dorner

Investing in proper damage prevention strategies protects products, reduces costs, and improves customer satisfaction while maintaining efficient operations. The initial investment typically pays for itself through reduced losses and improved efficiency, making damage prevention both a quality imperative and a sound business decision.

Contact Dorner today to evaluate your current transfer points and design customized solutions that deliver measurable results for your specific application.