Dorner Mfg. will be exhibiting several of its major conveyor platforms aimed at the food, packaging, industrial, automation, and life sciences industries; including a product preview of their Edge Roller Technology, in booth No. 5014, at WestPack 2020, Feb. 11-13, at the Anaheim Convention Center in Anaheim, California.

Dorner has developed a revolution in conveyance technology, which is Edge Roller Technology. The soon to be released technology provides the capability of low back pressure accumulation, non-contact zoning, and conventional transport all within the same basic conveyor package. Simple, yet robust, the design provides long-term durability and ease of single point roller maintenance. The clean design, open drive rollers, low voltage motors and controls, and aluminum framework all blend perfectly to provide the ideal edge roller conveyor for medical products, medical devices, and industrial product assembly and manufacturing.

Another one of Dorner’s conveyor platforms on display will be the redesigned AquaGard 7350 V2 Series, which includes the safest, most advanced modular curve chain sanitary conveyor in the industry today. The modular belt curve conveyor has no openings greater than the international standard of 4mm, even within the curves! The AquaGard offers increased safety by eliminating pinch points for operators. Additionally, added safety measures are achieved by covering the upper and lower chain edges, and fully containing the drive system, which reduces catenary belt sag and conveyor noise.

Dorner’s AquaGard 7350 modular belt curve conveyor has no openings greater than the international standard of 4mm, even within the curves.

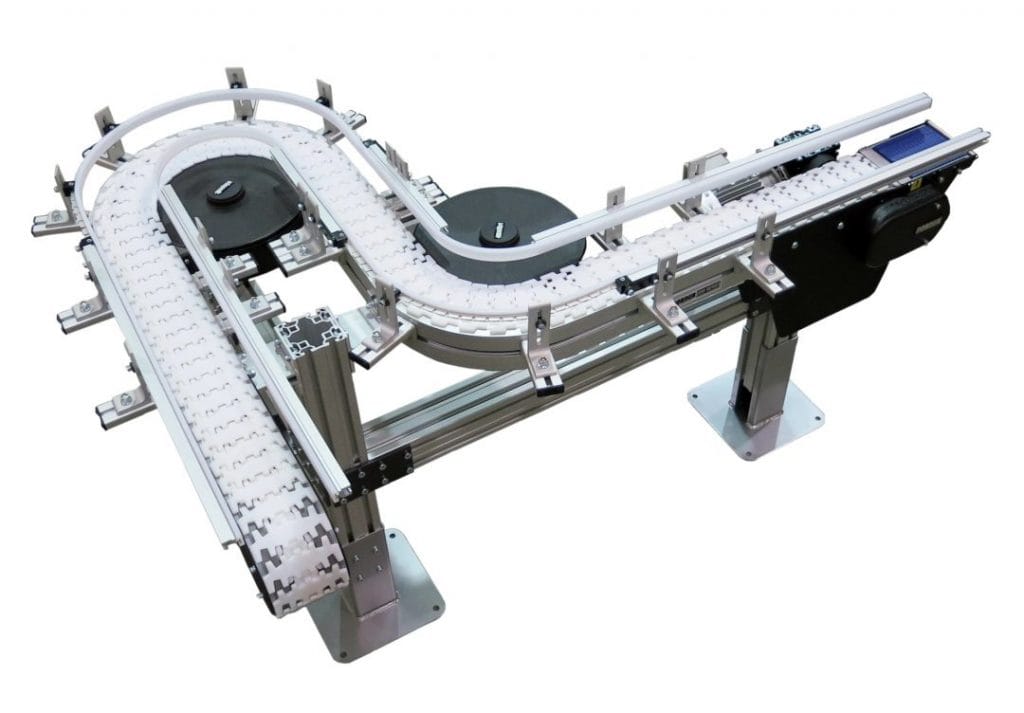

If you are looking for the utmost flexibility in conveyance, Dorner’s FlexMove flexible chain conveyor will be on display boasting both a 180 degree and 90-degree corner. This conveyor also features adjustable guiding and a powered transfer module that allows for smooth end transfers for products as small as 3” diameter. FlexMove conveyors are ideal for automation, material handling, packaging, general manufacturing, and integrators.

Unsure of which conveyor is right for your application? Dorner’s Engineered Solutions Group is a full-service team offering whole-scope services to produce a range of custom conveyor systems. Whether your business requires conveyors for work holding and elevation changes, line access and/or multiple belts, ESG can create custom conveyor solutions that will streamline your facility’s operations, elevating your business. WestPack 2020 is the perfect opportunity to discuss your custom conveyor solution with a conveyor specialist!

Whether your business’ needs are simple or complex as well as small or large, you can be assured that the Dorner team is committed to providing high-quality, first-rate solutions that deliver the greatest value and optimal fit for all your specific applications. To see how all these conveyor platforms can help your material handling applications, make plans to visit Dorner in booth No. 5014 at WestPack 2020.