Dorner’s ability to create the perfect solution for almost any application has been the defining factor that positioned us as… Read more »

Category: Conveyor Automation

3 Predictions for Upcoming Changes in The Conveyor Industry

The conveyor industry has been a cornerstone of modern manufacturing and material handling for decades, revolutionizing production lines and streamlining… Read more »

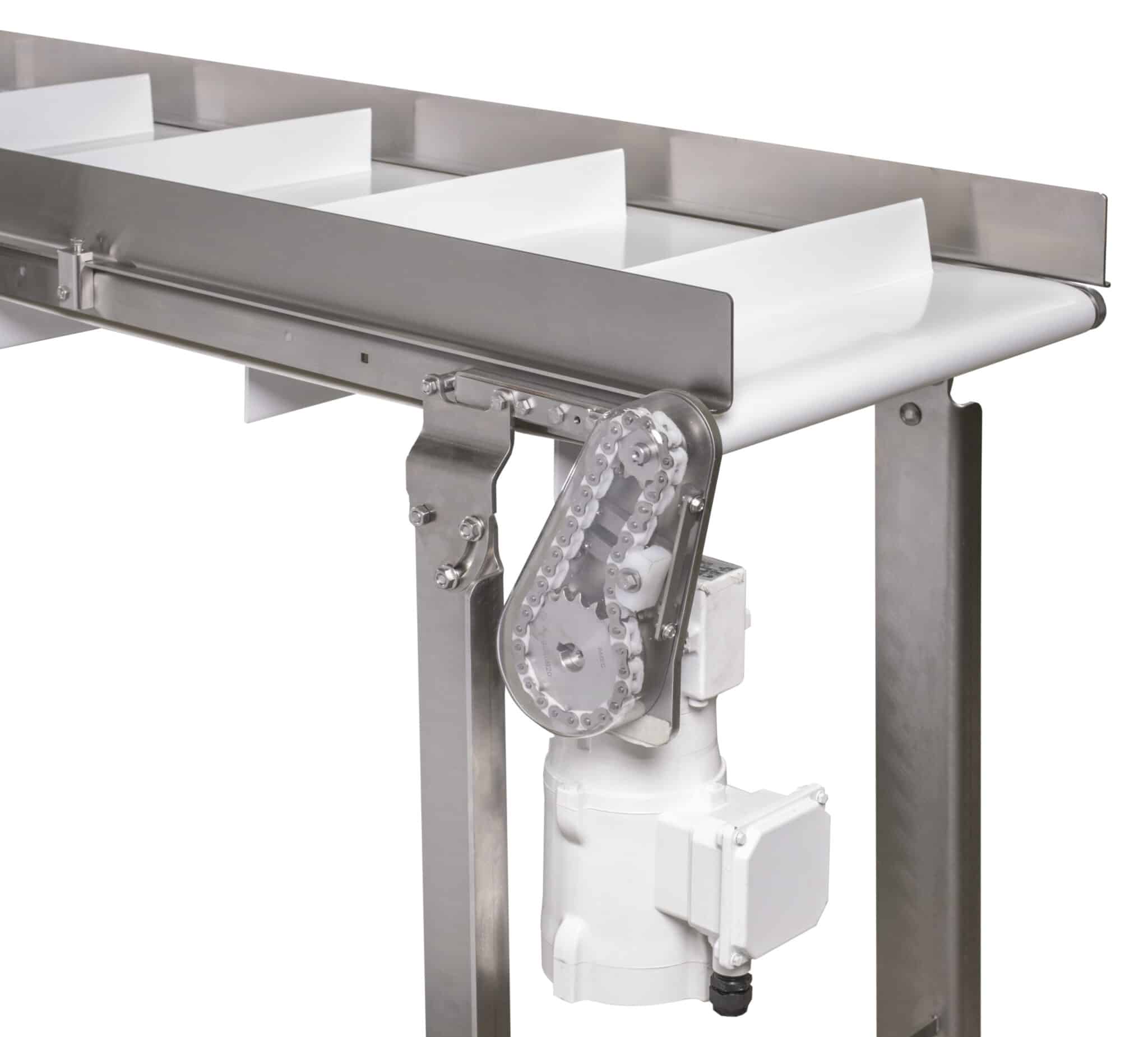

Présentation de l’AquaGard LP, le nouveau convoyeur à profil bas de Dorner Europe

Le NOUVEAU convoyeur AquaGard LP Le nouveau convoyeur AquaGard LP de Dorner Europe est conçu pour s’adapter aux espaces… Read more »

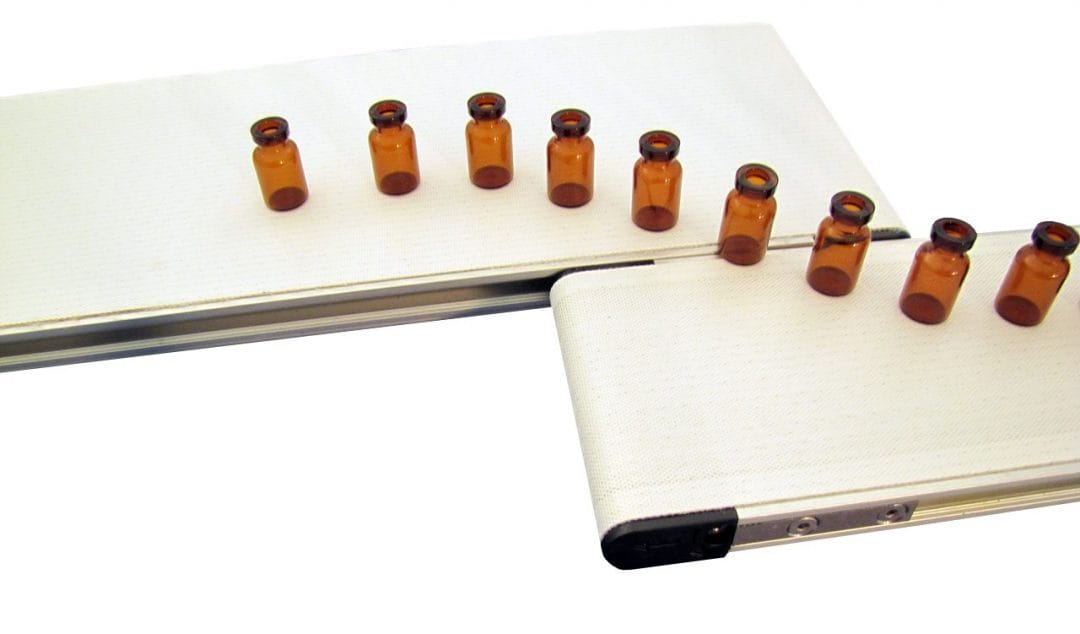

Custom Conveyor System for Medical Devices

During the peak of the COVID-19 pandemic, automation proved to be an essential aspect of manufacturing. Many companies were… Read more »

Increasing Efficiency with Warehouse Automation

One of the biggest challenges for businesses across industries is managing their warehouse and material handling processes efficiently and accurately.… Read more »

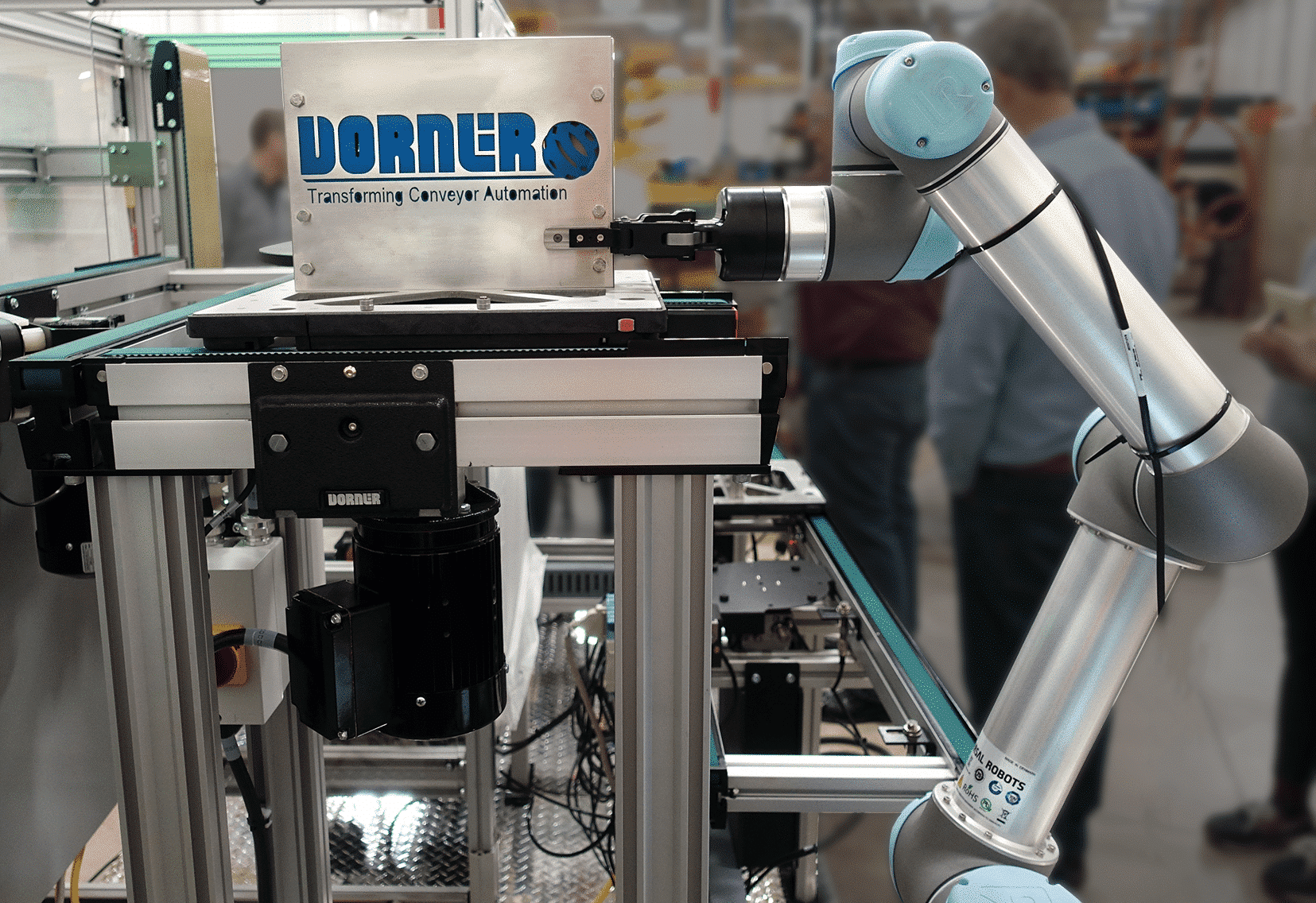

Pros and Cons of Integrating Robotics in Manufacturing

As technology continues to progress towards new innovations in automation, it is no surprise that the robotics industry is… Read more »

Pair Dorner Conveyors with Garvey Accumulators

Dorner partners with many organizations to bring top-of-the-line conveyance products and systems to our customers. In this new series,… Read more »

How to Amplify Your Conveyor System with Robotics

This article originally appeared in the May 2021 version of Design World. The integration between conveyors and robotics has… Read more »

Improve Production Line Efficiency with Industrial and Automation Conveyors

Industrial and automation conveyors are a crucial part of any production facility. They move parts and product from one… Read more »

Conveyors Are Fulfilling Key Roles in E-Commerce Applications

When it comes to both conveyors and online orders, quick delivery is king. Nowhere is that more prevalent than over… Read more »

Speed Up Your Process with Cleanroom Conveyors

Are changing demands impacting your business? Dorner’s variety of cleanroom verified conveyors* are designed to keep your products and customers… Read more »

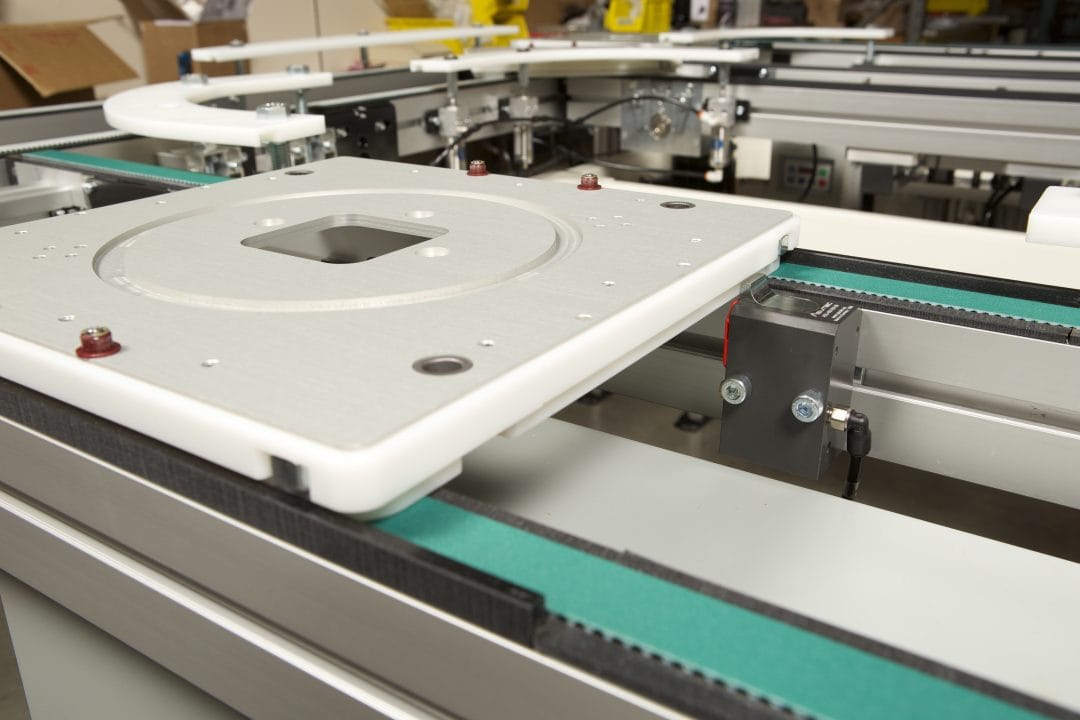

Tote System Simplifies Pharmacy Automation

Traditional pharmacies are often largely manual processes that require employees and pharmacists to carry orders around by hand. This can… Read more »

Add Simple Automation with Retractable Conveyors

A retractable conveyor, or retracting tail, is a conveyor frame with the ability to retract or extend, typically on… Read more »

See Dorner’s Conveyor Transfers in Action

Dorner’s industry leading transfers are designed to efficiently move your product while preventing product loss. Whether you’re transferring in-line,… Read more »

Staying Competitive with Automation

By John Kuhnz, Vice President – Engineered Solutions Increasing the speed of their packaging line is one of the leading… Read more »

Dorner Has Your Material Handling Needs Covered

Dorner’s Material Handling Conveyors are designed to handle all stages of the manufacturing process, from production and assembly through… Read more »

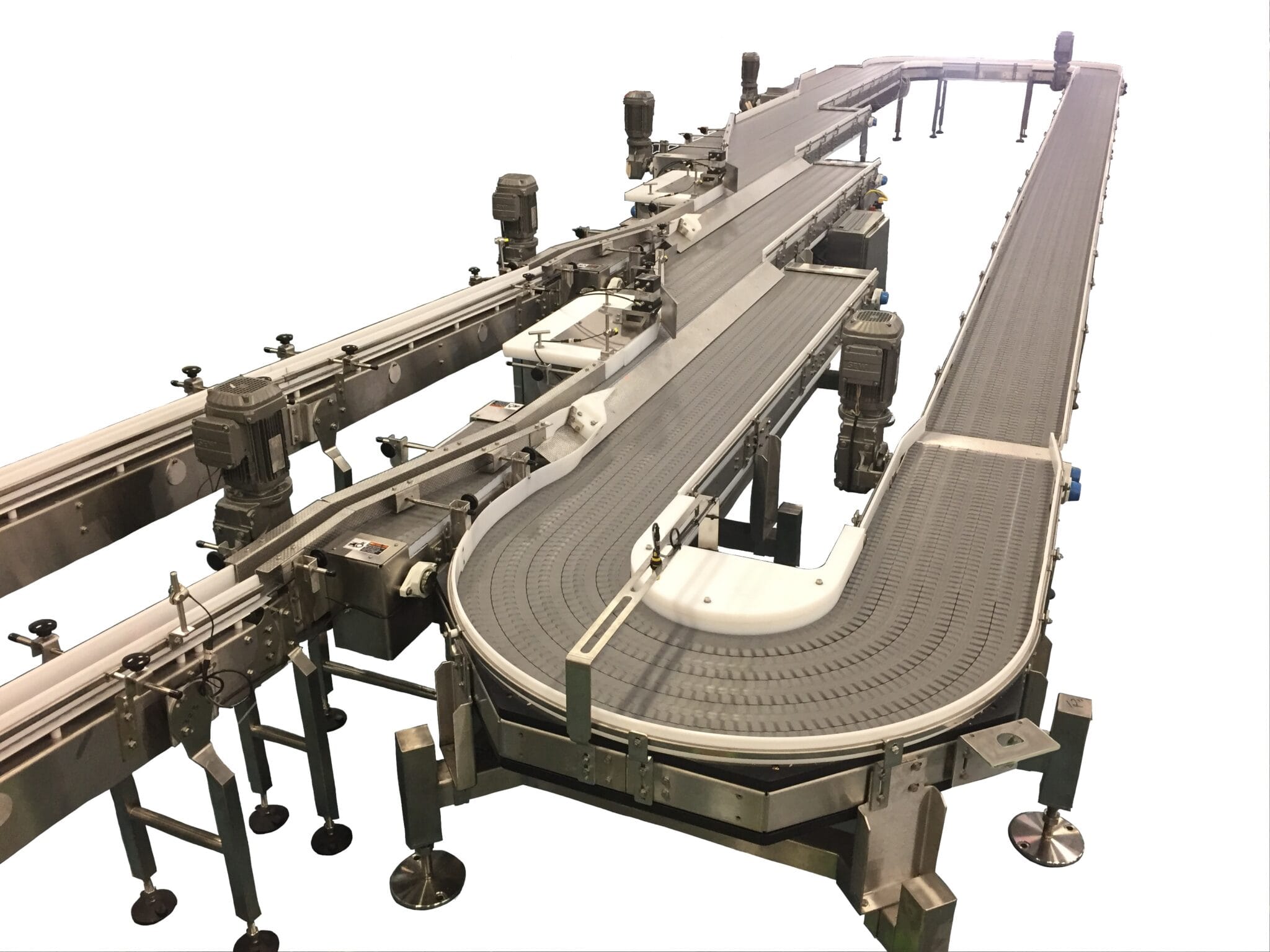

Case Handling System using 3200 Series Conveyors with Intralox ARB Technology

In a recent application, a customer needed a flexible system that could handle many different sizes and patterns of… Read more »

Increase Throughput and Efficiency with a Tote Handling System

See this system in action at the end of the post! Recently, a pharmaceutical company came to Dorner looking for… Read more »

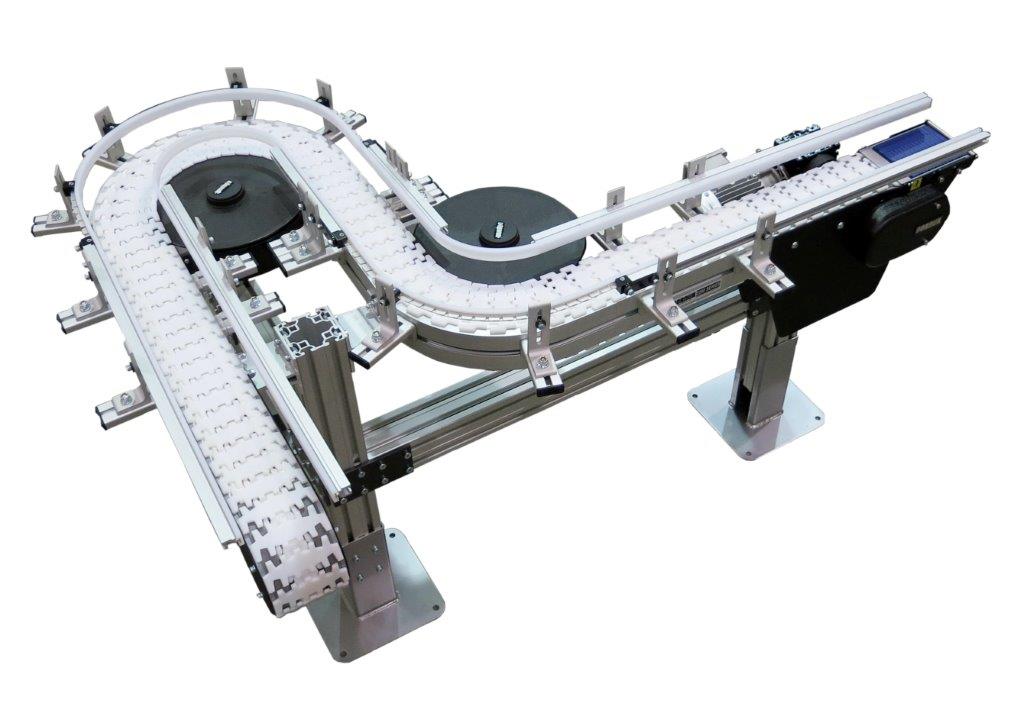

Lift Gate Provides Added Flexibility to SmartFlex System

Dorner’s 2200 Series SmartFlex conveyors are one of our most flexible systems available. For this application, the customer was… Read more »

Vertical Precision Move Conveyor for Elevation Changes in Manufacturing Line

Manufacturing lines aren’t always on a single level. For this paper company, the product accumulator was 20 feet above the… Read more »

Reducing Product Loss

When you need to move product from one conveyor to another that’s often where challenges arise. You could just put… Read more »

Belt or Chain, Belt vs. Chain – Not Really

What makes a belt better than a chain and vice versa? The answer is nothing. Belts are no better than… Read more »

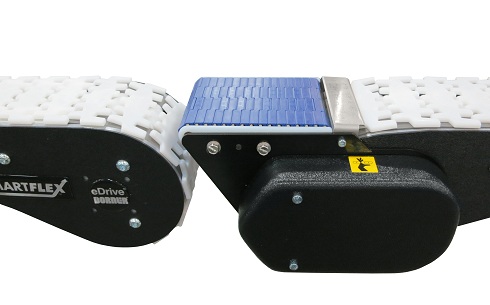

SmartFlex® Conveyors – Installation Made Easy

Dorner’s SmartFlex conveyors are designed and shipped to keep things simple! Each conveyor is completely assembled and tested at Dorner.… Read more »