Often it’s simple solutions that provide the most efficiency for our customers. For a manufacturer of body care products, the aim was to make the production process safer while at the same time, more effective and efficient.

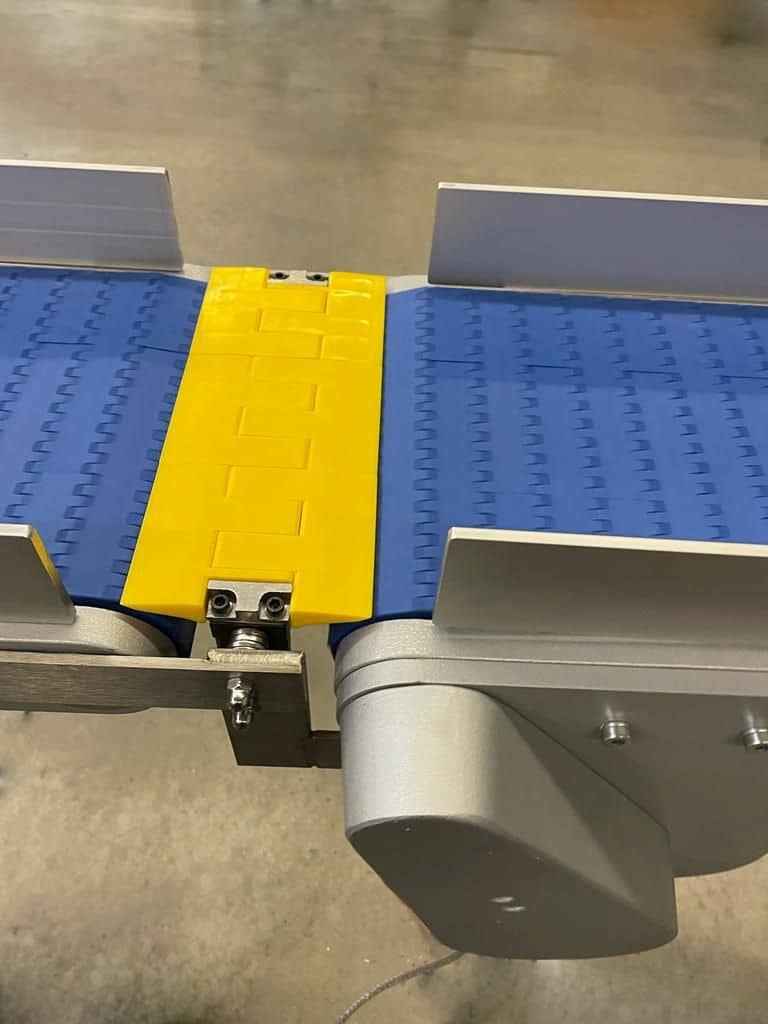

Dorner suggested the customer integrate so-called segmented transfer plates between modular belt conveyors in a new plant. These extremely robust plates made of HDPE plastic form a smooth transition. The cardboard boxes to be conveyed can therefore not get jammed between the conveyors, and a higher level of work safety is also ensured, as there is no longer a risk of crushing at the belt ends. With these added benefits, production downtimes are reduced or completely avoided.

In our experience, it is also usually possible to retrofit existing systems with modular belts and textile belt conveyors with transfer plates. Contact us if you’d like to learn more about integrating smooth transfers on your production line.