Thomas F. – Leading Innovation and Excellence at Dorner EMEA

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

With new medical discoveries being made seemingly every day, the medical device industry must quickly evolve to create new and

In the bustling world of pet food manufacturing, efficiency, safety, and precision are paramount. From ingredient processing to inspection and

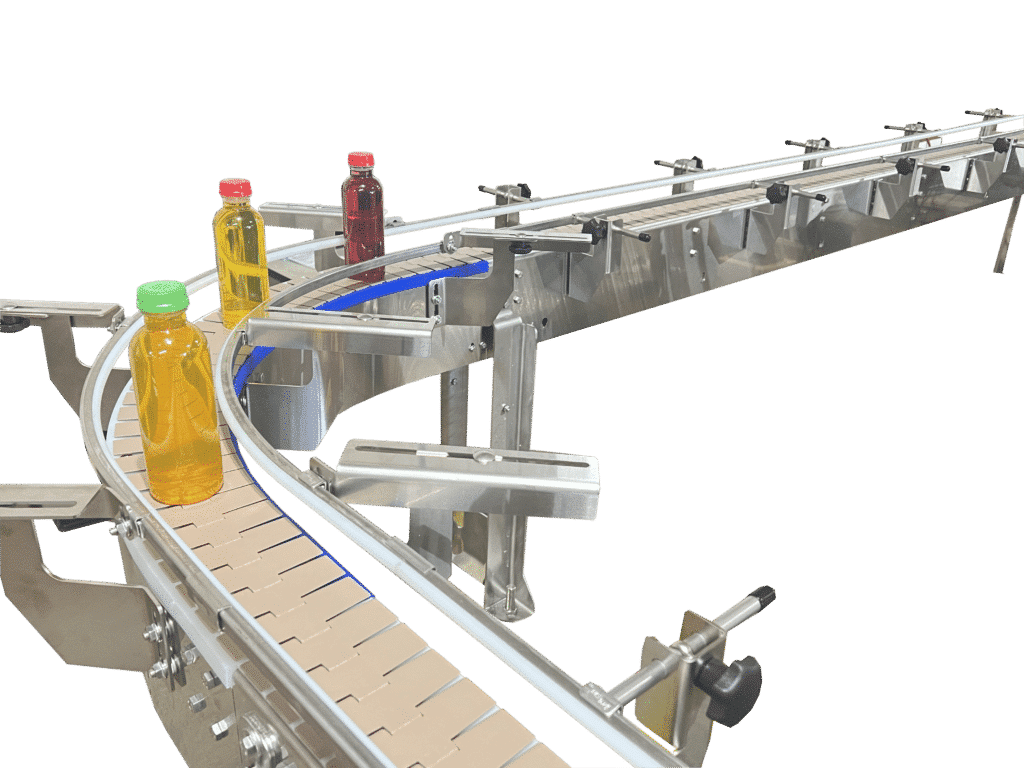

The AquaGard GT offers a truly unique conveyance solution for packaged food and beverage applications. Utilizing a flexible chain belt

At Dorner we are committed to constant innovation and improvement to meet the evolving needs of our customers. We are

Recently, Dorner Europe helped create a unique conveyance system for Pfeifer & Langen, a leading sugar manufacturer in Europe. The

Ready-to-eat foods have come a long way since the TV dinners of our parents’ and grandparents’ childhoods. From compartmentalized aluminum

Leading meat producers are continuously challenged to improve production line efficiency while adhering to the stringent hygiene standards of the

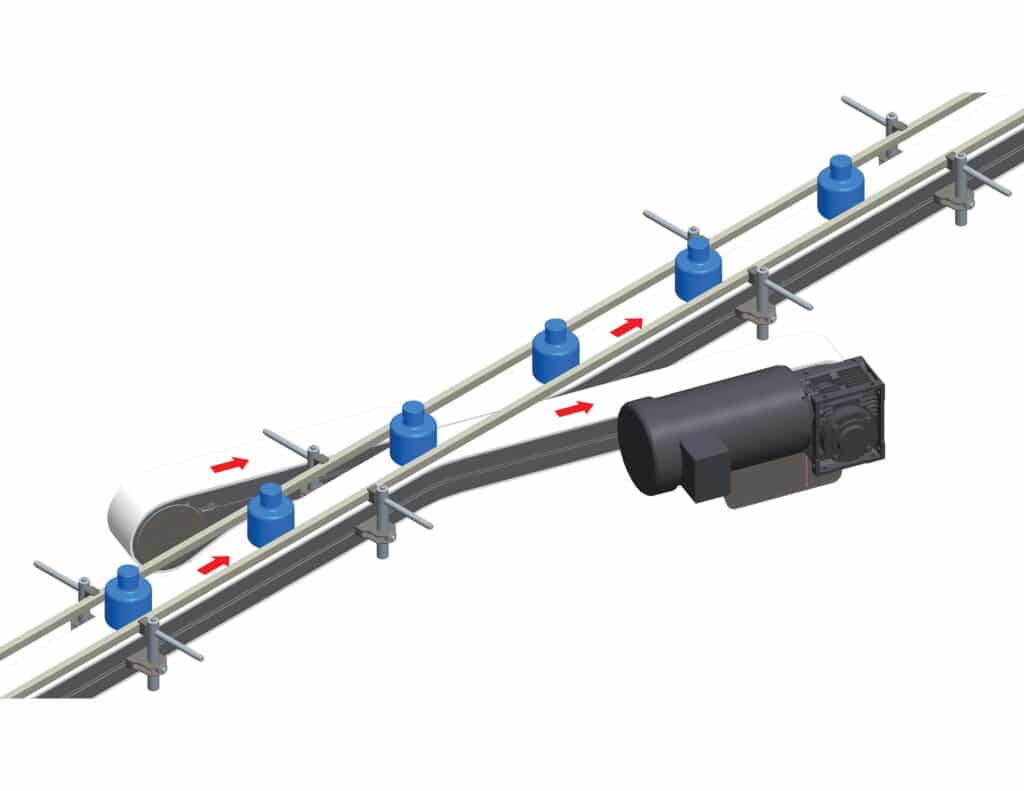

We are happy to announce some new features to our FlexMove flexible chain conveyance solution. These additions further the complete

Pack Expo East is just around the corner, and Dorner will again be sharing a booth with Garvey to showcase

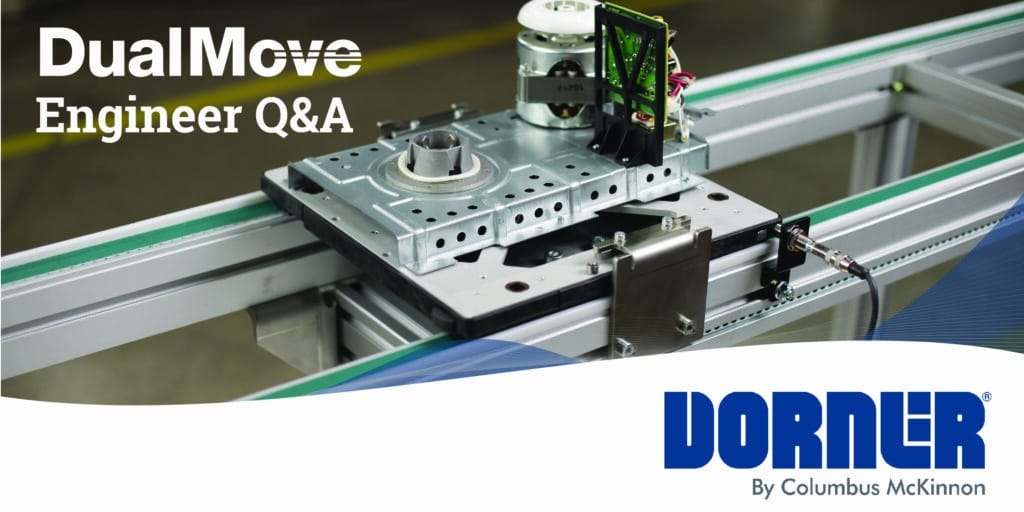

Discussion with Dan E., Anete F., & Marco P. As the latest addition to Dorner’s line of pallet system conveyors,

Dorner’s ability to create the perfect solution for almost any application has been the defining factor that positioned us as

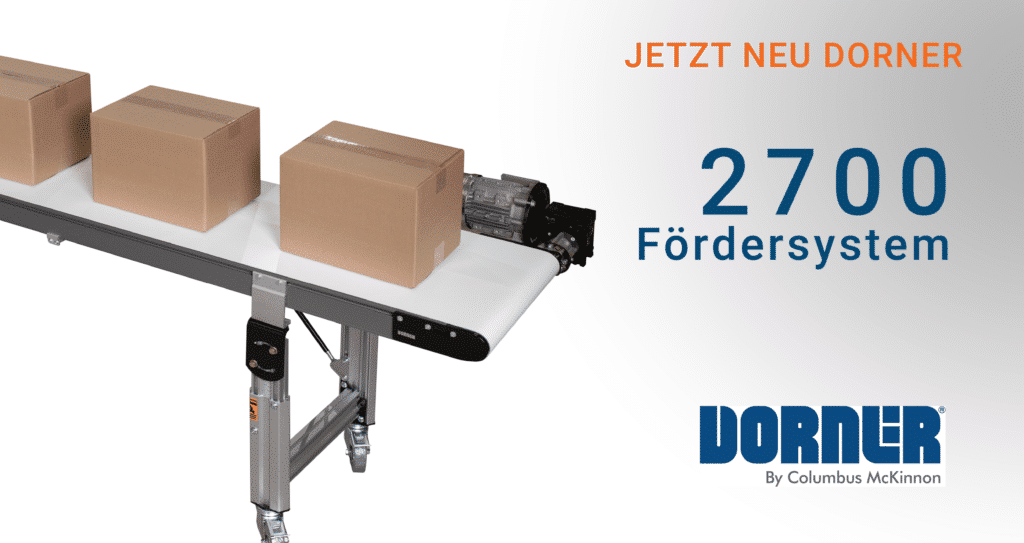

Unser Fördersystem 2700 ist die neueste Version der Dorner Präzisionsförderer mit niedrigem Profil. Mit der erhöhten Tragfähigkeit und erweiterten Breiten

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy

We may place these for analysis of our visitor data, to improve our website, show personalized content and to give you a great website experience. For more information about the cookies we use open the settings. Privacy Policy.