Dorner recently worked with a customer who needed to convey small plastic bottles. The solution required a number of different… Read more »

Schlagwort: Smart Solutions

SmartFlex Wedge Elevator Video

Dorner’s SmartFlex Wedge Elevators are designed to move products securely between the production floor and other elevations. The products… Read more »

Vertical Precision Move Conveyor for Elevation Changes in Manufacturing Line

Manufacturing lines aren’t always on a single level. For this paper company, the product accumulator was 20 feet above the… Read more »

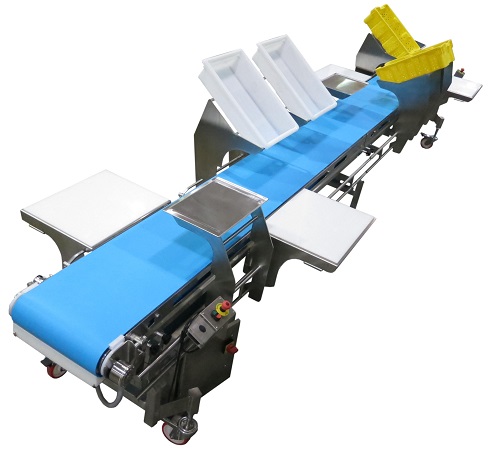

Improving a Ready-to-Eat Assembly

Recently, one of our customers requested a versatile assembly conveyor for its popular ready-to-eat sandwich products. To meet their needs,… Read more »

Dorner’s D-Tools Configurator

Have you tried Dorner’s Conveyor Configurator? This tool gives users the control to design and engineer complete conveyor packages or just… Read more »