In modern manufacturing facilities, space is premium, and every piece of equipment must work in sync with other machinery and… Read more »

Kategorie: Engineered Solutions

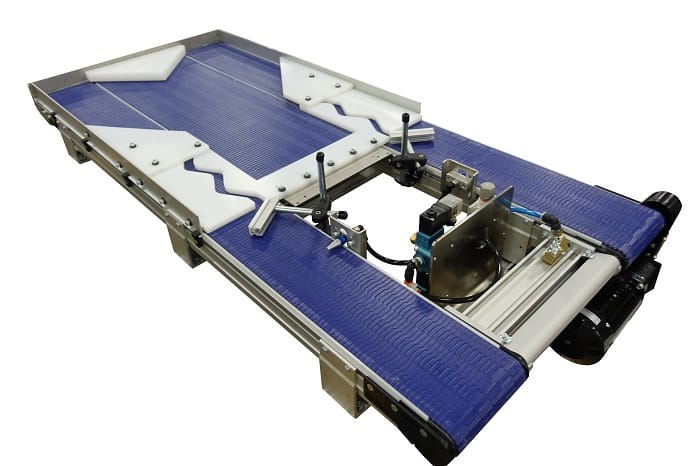

New Conveyor Projects in the Shop

The new year has brought many new projects into the shop at Dorner’s Hartland facility, and our Engineered to Order… Read more »

4 wichtige Faktoren für die Auswahl eines Fördersystems

Bei der richtigen Wahl eines Fördersystems, das sowohl den Anforderungen der jeweiligen Branche als auch den individuellen Bedürfnissen… Read more »

Lösungen bei Platzmangel durch Höhenverkettung mit Steigförderern

Warum Systeme flexibel sein müssen Moderne Fertigungsanlagen müssen Effizienz maximieren und Produktqualität sicherstellen. Fehlender Platz kann diese Ziele jedoch… Read more »

Easy 90 Degree Transfers

Controlling product flow doesn’t have to be complicated. With 90 degree transfers it can be as easy as moving off… Read more »

Save Time and Money with Dorner’s Engineered Solutions

Do you have an application that calls for an extra-long conveyor, but an existing obstruction is hindering the installation of… Read more »

Elevator Provides Additional Product Storage for Accumulation System

See the system in action at the end of the post! When downstream equipment is non-operational, an accumulation system can… Read more »

Retractable Tail Provides Simple Walk-Through Access

Space can be limited on the factory floor and equipment isn’t always easy to access. Conveyors and other machinery… Read more »

Merging and Laning System for Sauce Packaging

Often during the packaging process, product needs to be either merged or separated into separate lanes as it moves… Read more »

Create Safe and Fast Walk-Through with Lift Gates

Lift gate conveyors are a popular solution for creating safe and fast walk-through access to maximize usable space. Take… Read more »

Can Dorner Design A Solution For Your Application?

Dorner’s Engineered Solutions Group (ESG) can create a custom conveyor or conveyor system for almost any customer need. Dorner has… Read more »

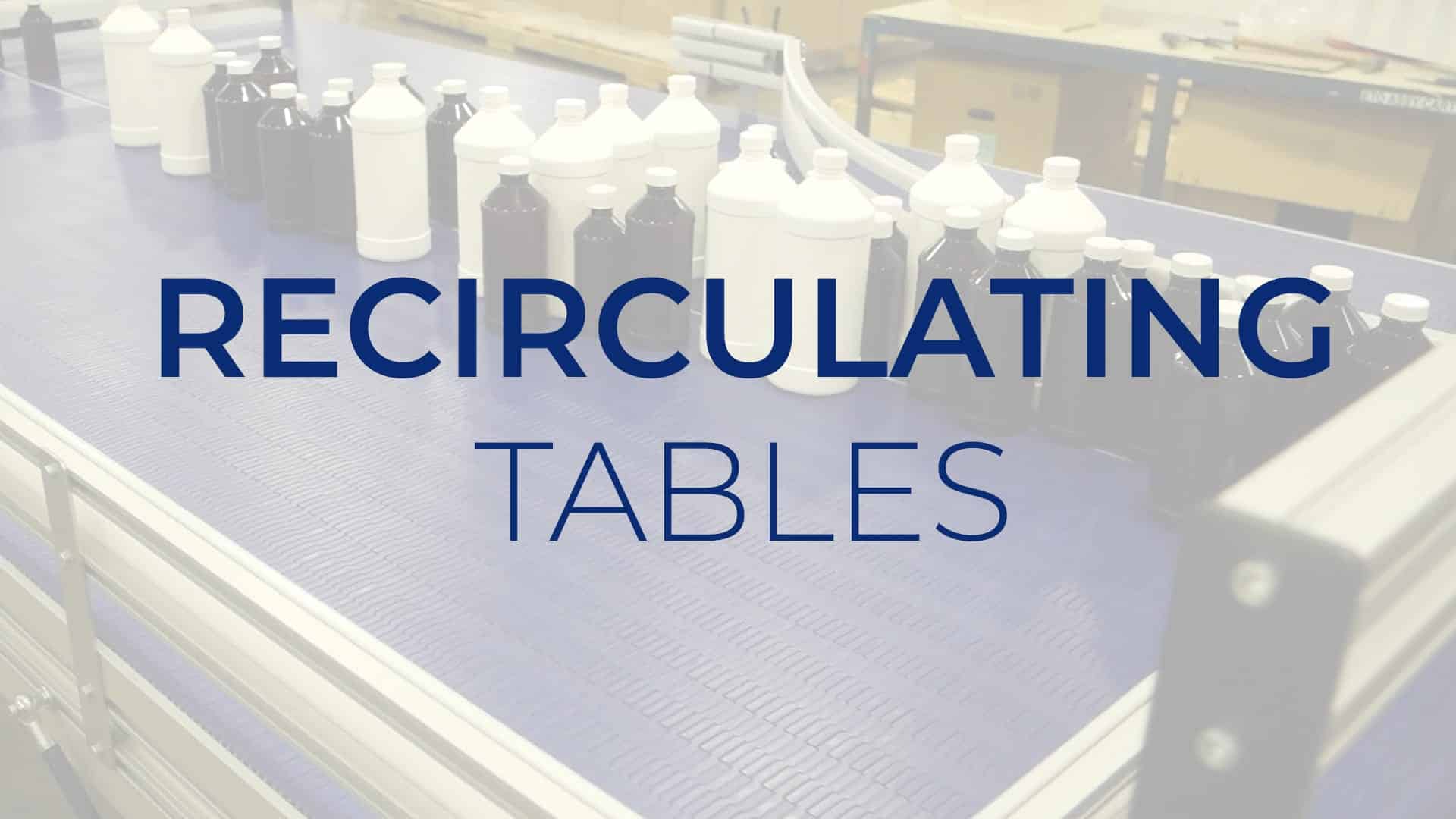

Fünf wichtige Fakten zu Dorners Puffertischen

Sehen Sie unsere Puffertische in Aktion am Ende des Beitrags! Puffertische, auch unter den Produktbezeichnungen Stautische, Speichertische bekannt, sind sogenannte… Read more »

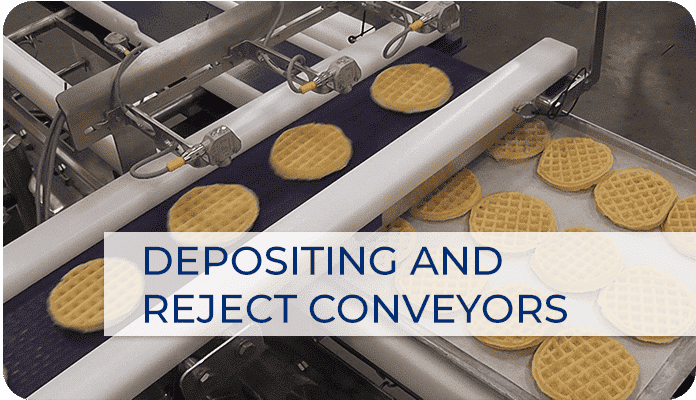

Dorners kundenspezifische Einlege- und Ausstoßfördersysteme

Ausstoßförderbänder Warum ist Ausstoßen notwendig? Das Ausstoßen ist ein notwendiger Schritt in jeder Produktionslinie, um die Qualität der Produktion… Read more »

Einfache Automatisierung: mit ausfahrbaren Förderbändern von Dorner

Durch eine Einziehfunktion, die das Ende eines Förderbandes aus- und einfährt, erreichen Förderbänder eine hohe Funktionalität. Wahlweise manuell oder… Read more »

Wie funktionieren Umlenk- und Sortierförderer? Sehen Sie selbst.

Umlenk- und Sortierförderer arbeiten, indem sie Produkte auf der Grundlage von Merkmalen wie Gewicht und Form zusammen mit der Linienkapazität… Read more »

Eine einfache und hygienische Umlenklösung zur Erhöhung des Produktflusses

Weichen, Schieber und Tore werden eingesetzt, wenn die Steuerung des kontinuierlichen Produktflusses durch die Linie für die Aufrechterhaltung der… Read more »

Dorner Zusammenführungsförderer

Dorner bietet eine Vielzahl von Lösungen für die Zusammenführung von Produkten in einer Produktionslinie. Wir können 2, 3, 4 oder… Read more »

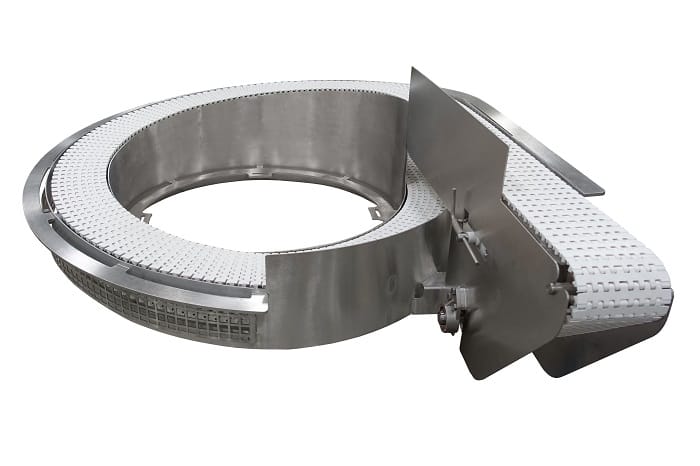

Sanitary Helix Now with Added Features

As we’ve highlighted in the past, Dorner has created Sanitary Helix designs to integrate with Hoosier Feeder’s Food Grade Centrifugal… Read more »

Custom Accumulation Systems

When you need to ensure a steady supply of product to a machine or to hold a supply of product… Read more »

Magnetic Conveyors Customized for Efficiency

Every business needing a magnetic conveyor in its facility has a specific product to run. Therefore, no two solutions… Read more »

Dorner’s Engineered Solutions Group Injects Automation and Ingenuity into Conveyor Systems for Complex Applications

When a customer needed to upgrade their existing food processing line to merge two lanes of frozen pizzas into… Read more »

Case Handling System using 3200 Series Conveyors with Intralox ARB Technology

In a recent application, a customer needed a flexible system that could handle many different sizes and patterns of… Read more »

Custom Frozen Pizza System

At Dorner, we can provide anything from a single conveyor to a full system. Recently, Dorner worked with a… Read more »

Increase Throughput and Efficiency with a Tote Handling System

See this system in action at the end of the post! Recently, a pharmaceutical company came to Dorner looking for… Read more »