Die erstklassigen Dorner-Förderer für die Lebensmittelbehandlung und -verarbeitung sind äußerst hygienisch und für den Betrieb mit hohen Geschwindigkeiten ausgelegt. Diese Förderer haben eine herausragende Erfolgsbilanz darin erzielt, Unternehmen dabei zu helfen, ihre Effizienz und Produktivität zu maximieren, um ihr volles Potenzial auszuschöpfen.

Wenn Ihr Unternehmen kundenspezifische Geräte für die Lebensmittelverarbeitung benötigt, ist Dorner in einer einzigartigen Position, um speziell angefertigte Systeme zu entwickeln, die die Vision unserer Kunden für einen verbesserten Workflow erfüllen.

Vorteile von Dorner-Förderern zur Handhabung und Verarbeitung von Lebensmitteln

Die lebensmitteltauglichen Förderer von Dorner bieten mehrere Vorteile, die sie ideal für die Lebensmittelindustrie machen. Mit Sanitärförderern von Dorner profitiert Ihr Lebensmittelherstellungsprozess von Folgendem:

Hohe Hygienestandards

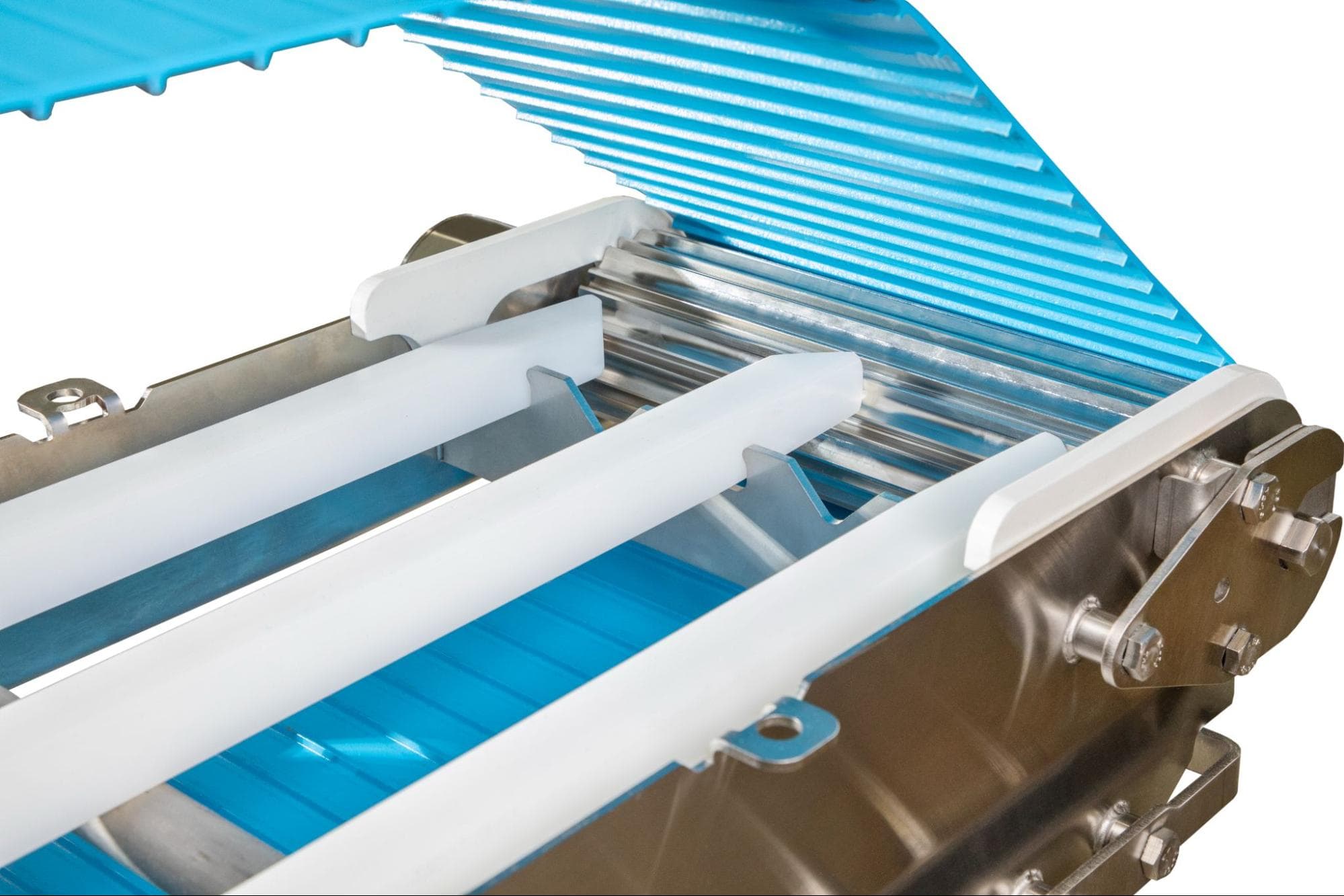

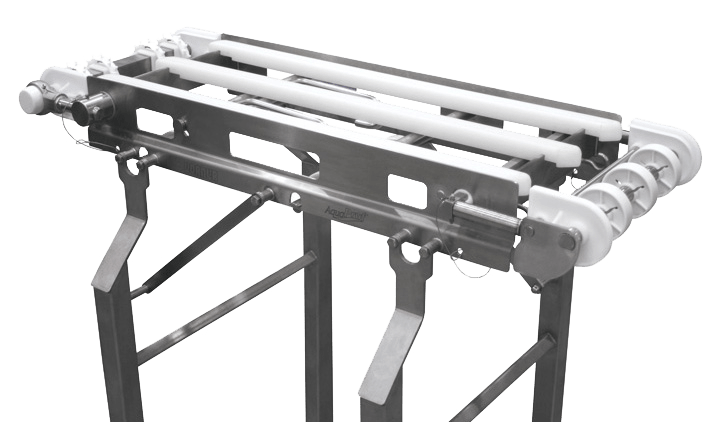

Jeder Sanitärförderer von Dorner ist mit einem flachen Profil und einer offenen Rahmenkonstruktion ausgestattet, die einen einfachen Zugang zur Bandoberfläche und zu den Innenkomponenten für eine schnelle und effektive Sanitärversorgung ermöglicht – mit einer 2x schnelleren Reinigung als die unserer Konkurrenten!

Unsere Lebensmittelfördersysteme verfügen über drei Hygienestufen, die für Ihre spezifische Anwendung konfiguriert werden können. Mit hygienischen Designs müssen unsere Fördersysteme weniger gereinigt werden, was Ihre Arbeit einfacher, sauberer und effizienter macht.

Verpflichtung zur Lebensmittelsicherheit des Förderbands

Als führender Anbieter von Förderbändern in der Lebensmittelindustrie bekennen wir uns dazu, unseren Kunden Förderanlagen zur Verfügung zu stellen, die hohe Lebensmittelhygienestandards einhalten und Ihre Gesamtanlageneffektivität verbessern. Wir verfolgen einen fünfstufigen Ansatz, um Ihre Branche zu bedienen und die Lebensmittelsicherheit zu fördern, darunter:

- Hygienedesign

- Einfache Hygiene

- Effektive Hygiene

- Einfache Demontage

- Sicherheit des Bedieners

Lesen Sie hier mehr über das Dorner-Engagement für Lebensmittelsicherheit:

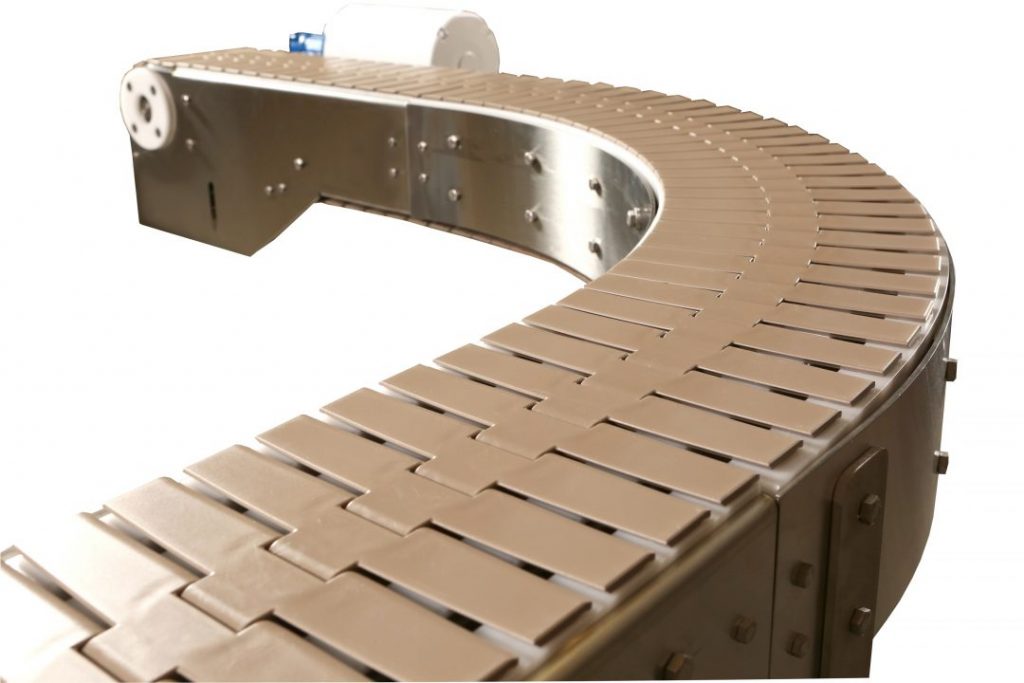

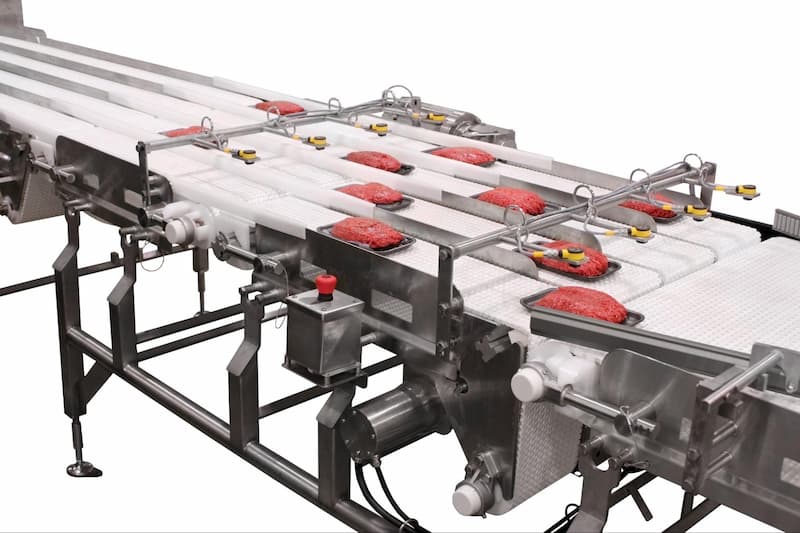

Kundenspezifische Lösungen für einzigartige Systeme

Unser Team versteht, dass jeder Herstellungsprozess und jede Anwendung einzigartig sind. Deshalb sind wir auf kundenspezifische Lösungen spezialisiert, die auf Ihre Bedürfnisse, Einschränkungen und präzisen Spezifikationen zugeschnitten sind. Ob Sie frische Produkte transportieren oder Fleischprodukte verpacken, wir können ein hochwertiges Fördersystem liefern, das Ihren genauen Anforderungen entspricht.

Dorner-Förderbänder bieten Sicherheit, die über Ihre Produkte hinausgeht

Dorners Förderer für die Lebensmittelbehandlung und -verarbeitung erfüllen die Industriestandards und -vorschriften sowie die Sicherheitsstandards für Bediener, darunter:

- BISSC (Baking Industry Sanitation Standards Committee)

- FDA (U.S. Food and Drug Administration)

- USDA (United States Department of Agriculture)

- RoHS (Restriction of Hazardous Substances)

- CE (Conformité Européenne)

- OSHA (Occupational Safety and Health Administration)

- ANSI (American National Standards Institute)

Anwendungen für hygienische Lebensmittelförderer

Bei Dorner steht die Lebensmittelsicherheit im Vordergrund. Wir verstehen die Bedenken und Herausforderungen, denen sich Teams in der Lebensmittelbranche gegenübersehen. Egal, ob Sie im Bereich Backwaren und Süßwaren, Milchprodukte und Käse, verzehrfertige Lebensmittel, Fleisch, Geflügel und Meeresfrüchte, Obst und Gemüse oder andere Lebensmittel tätig sind, unser Fördersystem der AquaPruf-Serie kann Ihre Anforderungen erfüllen.

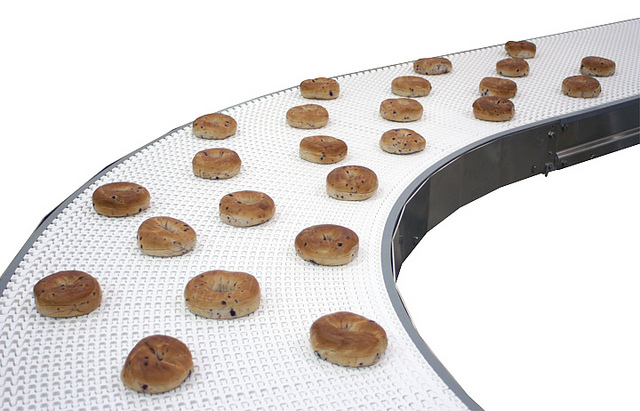

Akkumulation und Kühlung

Für maximale Effizienz können unsere Sanitärförderer in Akkumulations- und Kühlanwendungen für eine Reihe von Lebensmittelprodukten verwendet werden, sodass Sie die Produktion sicher aufrechterhalten können, während Sie Fertigprodukte (wie Backwaren oder Fertiggerichte) für die nächste Produktionsstufe sammeln. Fördern Sie eine effiziente, gleichmäßige Kühlung mit Präzisionsförderlösungen.

Inspektion und Metallerkennung

Automatisierte Lebensmittelförderbänder können dazu beitragen, den Inspektionsprozess während der Lebensmittelproduktion zu optimieren. Sie ermöglichen es den Bedienern, die Produkte auf ihrem Weg durch die Produktionslinie gründlich zu prüfen, um Anomalien oder Probleme zu erkennen und diese schnell zu beheben, ohne den Arbeitsablauf zu unterbrechen.

Waschen und Sortieren

Der richtige Sanitärförderer macht das Waschen und Sortieren bestimmter Produkte, wie frische Produkte, zum Kinderspiel. Unsere AquaPruf-Förderer wurden für eine einfache Reinigung entwickelt und können den Wasch- und Sortierprozess sicher und effektiv überstehen, ohne die Qualität Ihres Produkts zu beeinträchtigen oder Schäden am Fördersystem zu riskieren.

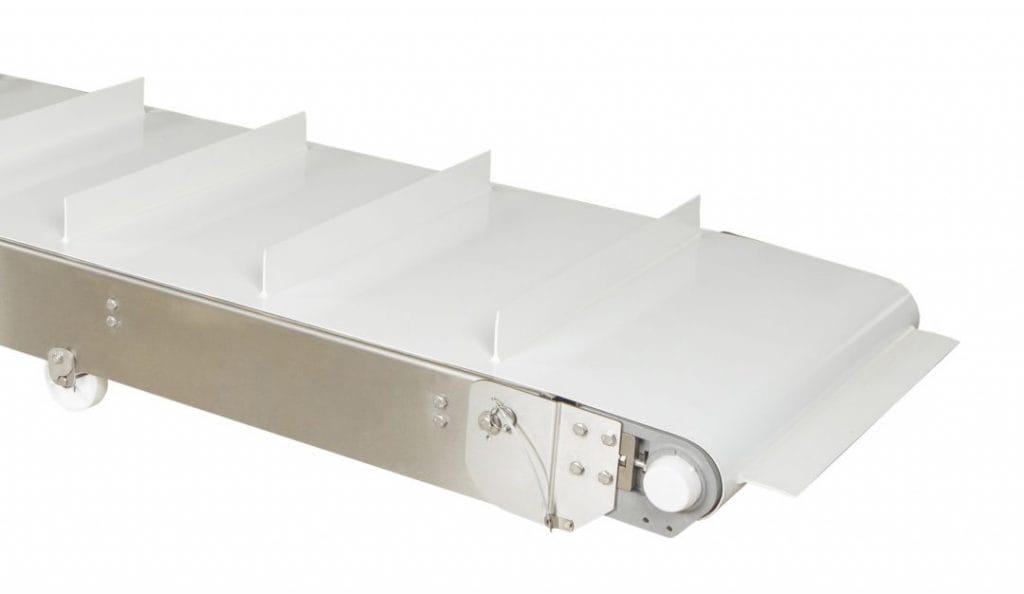

Verpackung

Wie in jeder Branche eignen sich unsere Förderer für die Lebensmittelverarbeitung gut zu Verpackungsanwendungen. Ganz gleich, ob Sie empfindliches Obst, rohes Fleisch oder Backwaren verpacken, unsere Fördersysteme sorgen dafür, dass Ihr Prozess reibungslos läuft. Mit den lebensmitteltauglichen Förderern von Dorner können Sie Pakete präzise bewegen und Produktverschwendung minimieren, während Sie mit den Anforderungen einer geschäftigen Produktionsumgebung Schritt halten.

Förderer für die Lebensmittelverarbeitung in jeder Kategorie

Dorner verfügt über das perfekte hygienische Fördersystem für Ihre Lebensmittelherstellungs- oder -handhabungsanlage, unabhängig davon, womit Sie arbeiten. Von Ein- und Ausspeiseanwendungen bis hin zu Kühl- und Inspektionslösungen helfen Ihnen unsere zuverlässigen lebensmitteltauglichen Förderer, die Arbeit in jeder Kategorie schnell, effizient und sicher zu erledigen.