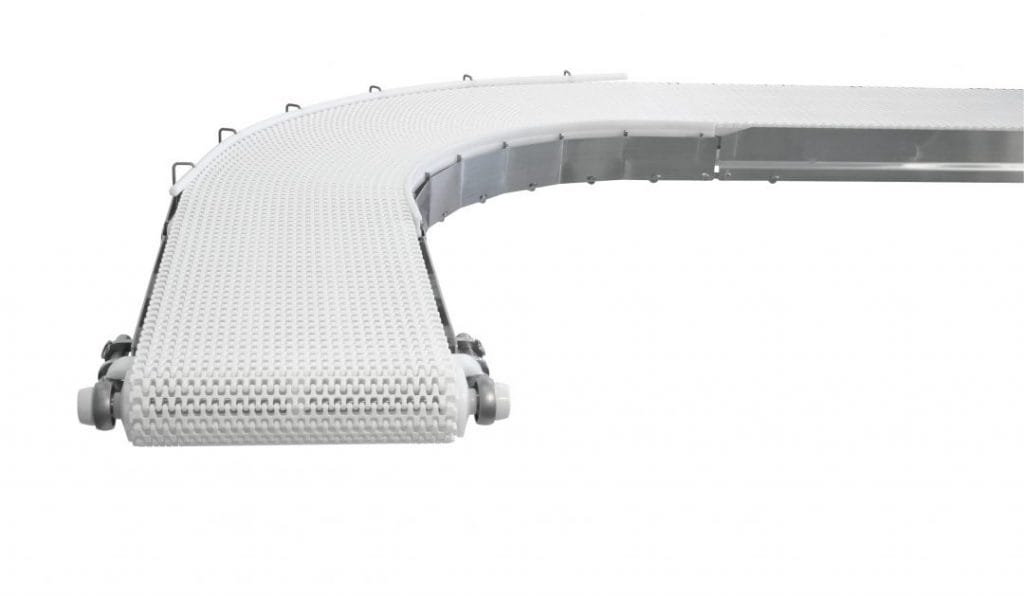

AquaPruf 7400 Förderbänder

Contact Us

Conveyor specialists are ready to help you find the right solution

Vorteile des AquaPruf 7400 Förderbands:

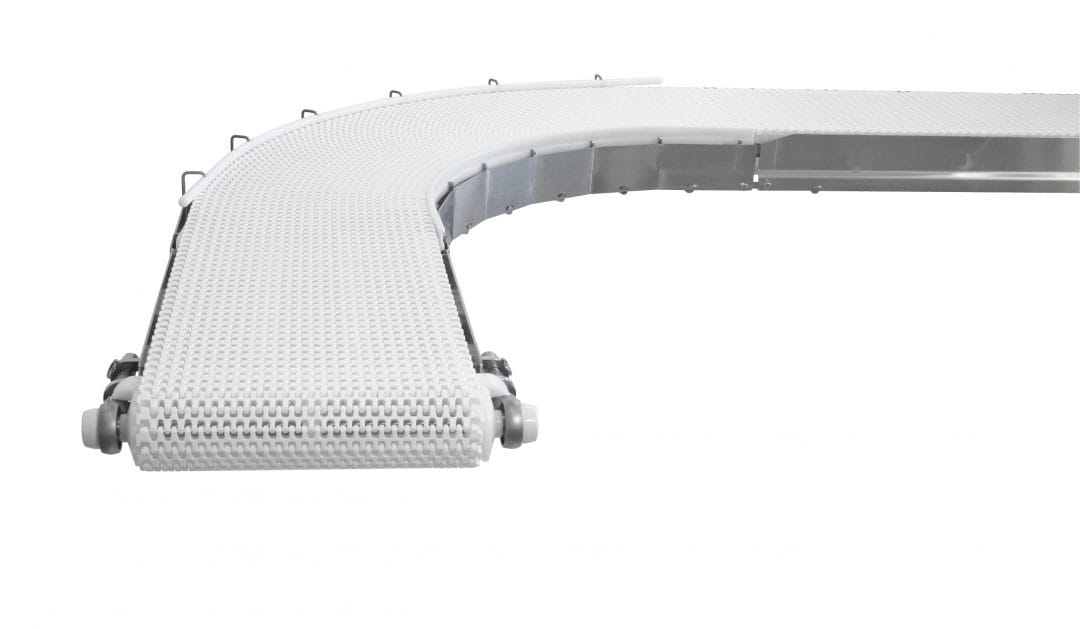

- Der Rahmen ist mit horizontalen Flächen konstruiert, für optimale Reinigung. Förderbänder von über 3,048 m (10’) Länge bestehen aus mehreren Abschnitten zum Zusammenschrauben.

- Für maximale Leistung in Spritzwasserbereichen sind die Lager in Gehäusen aus Edelstahlguss montiert.

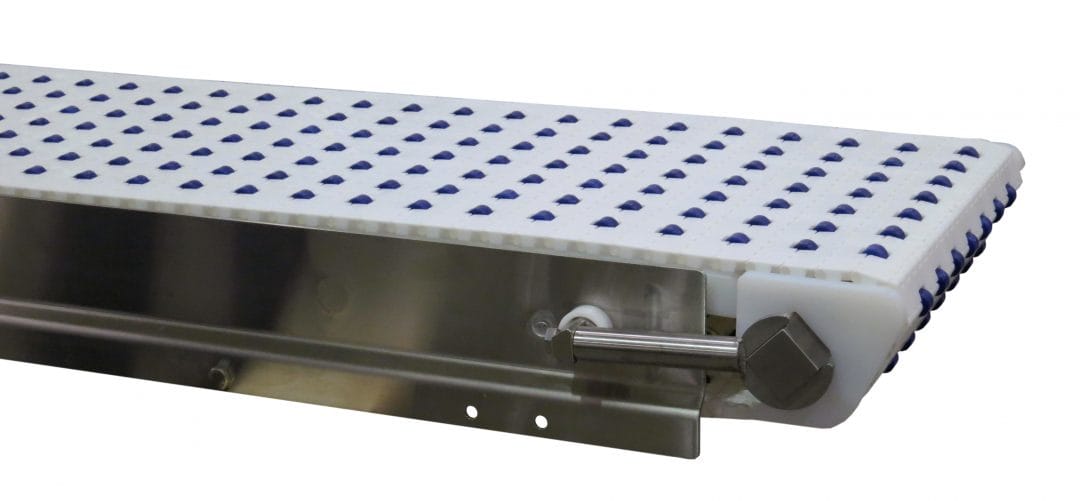

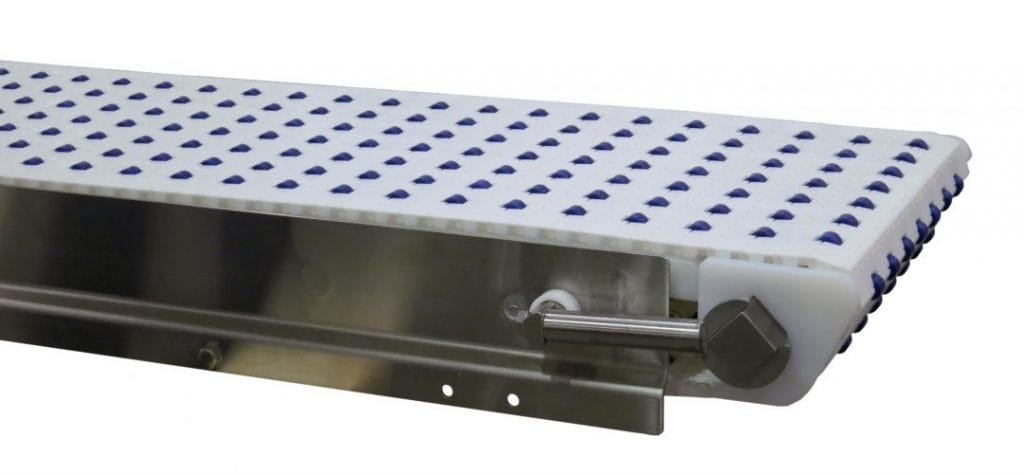

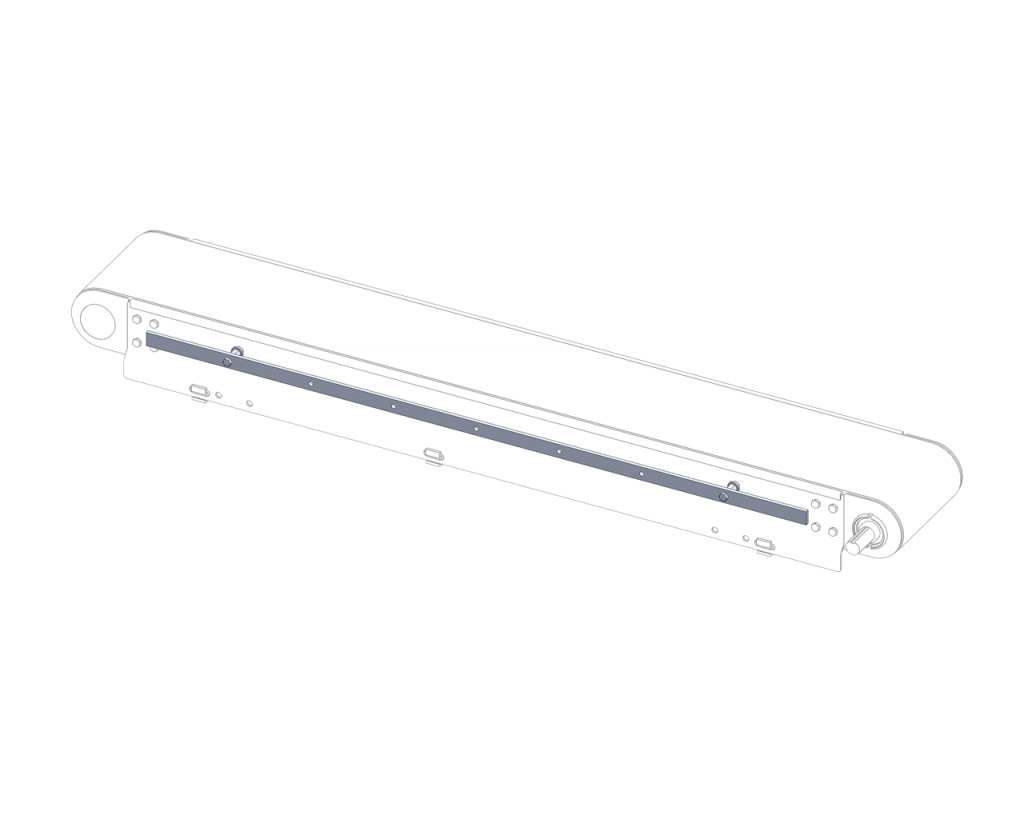

- Solide UHMW-Verschleißstreifen lassen sich leicht und ohne Werkzeug aus dem Rahmen heben; macht die Reinigungszeit minimal.

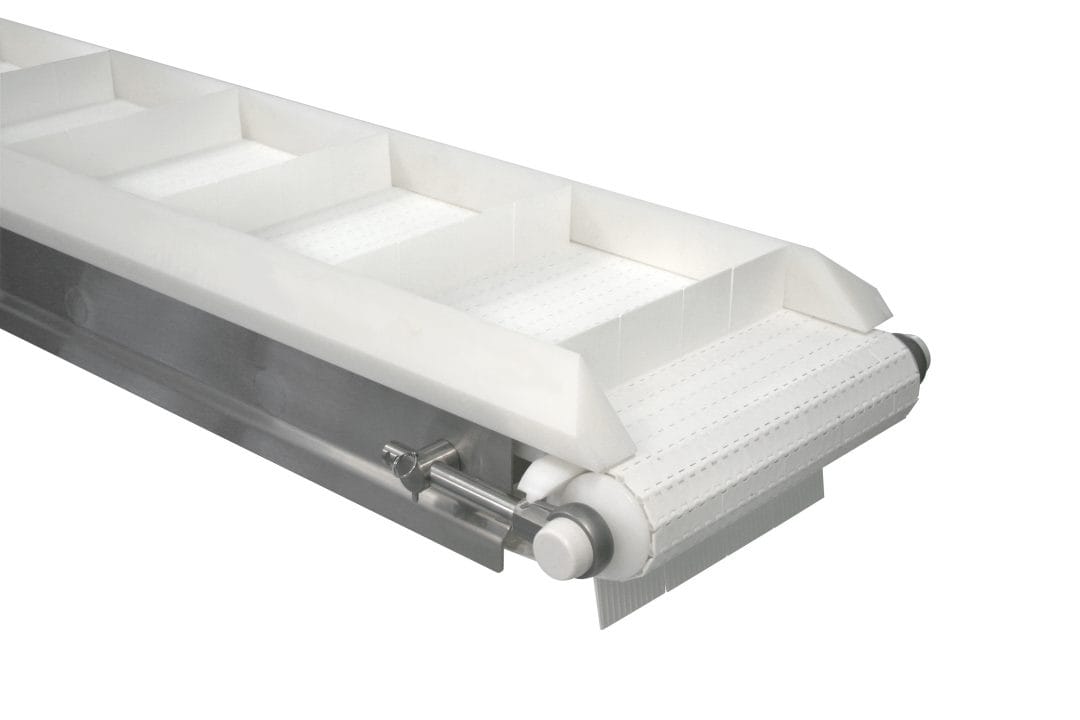

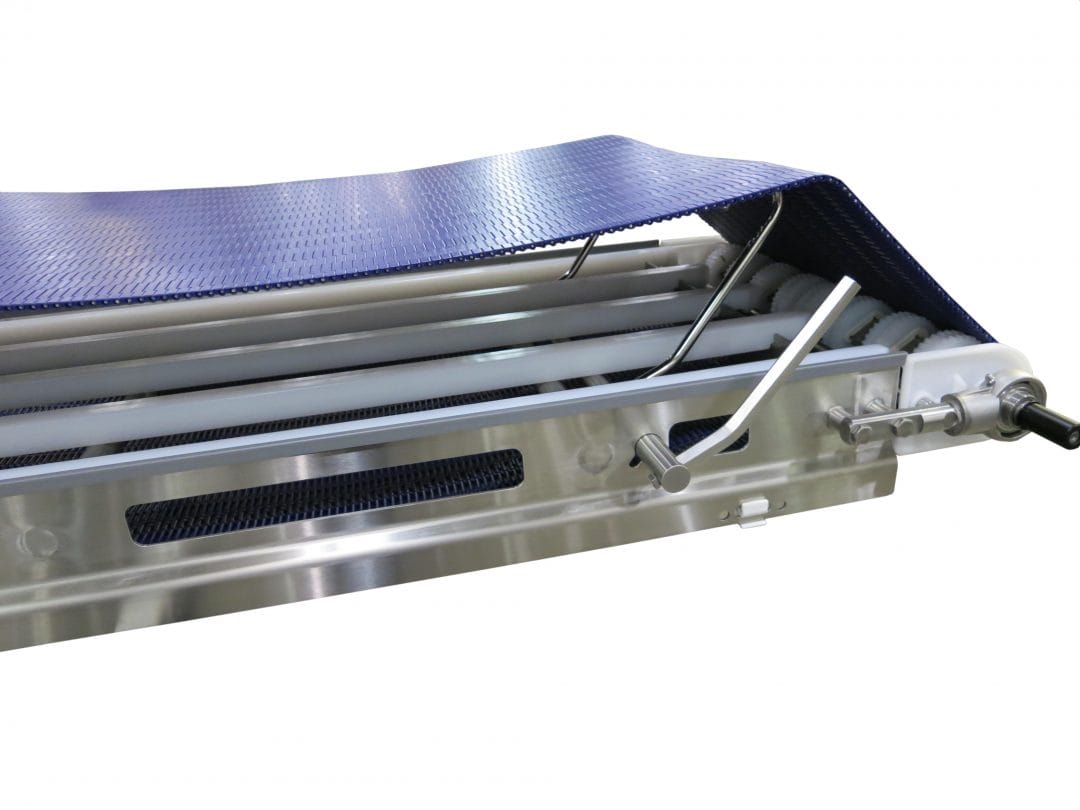

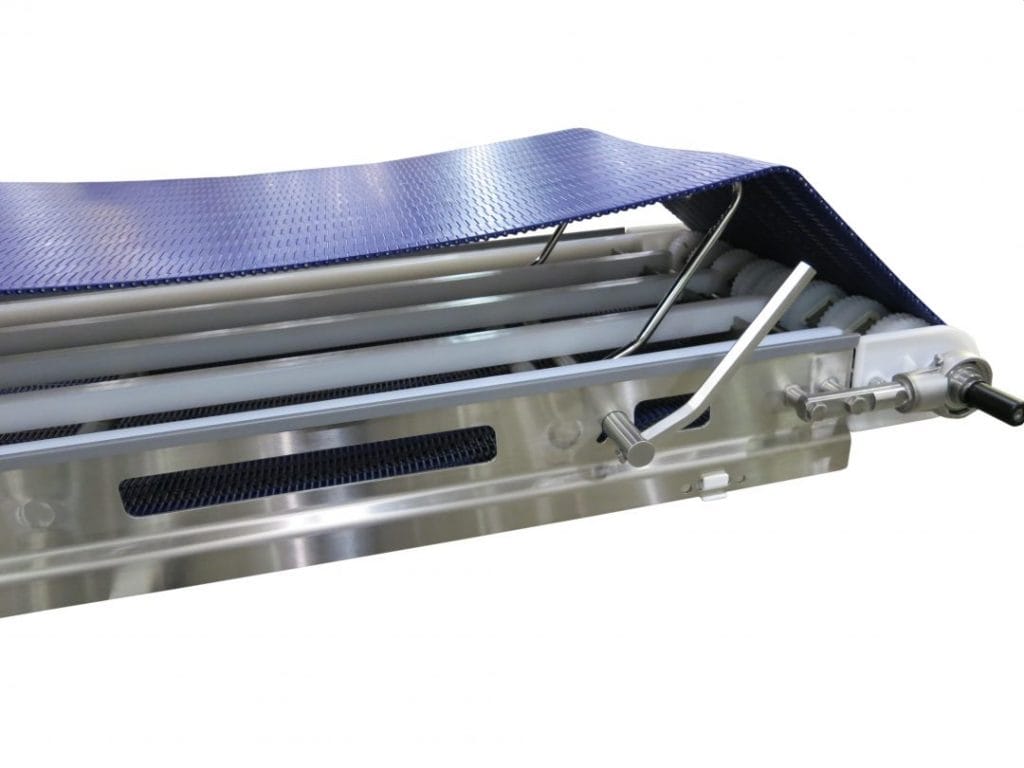

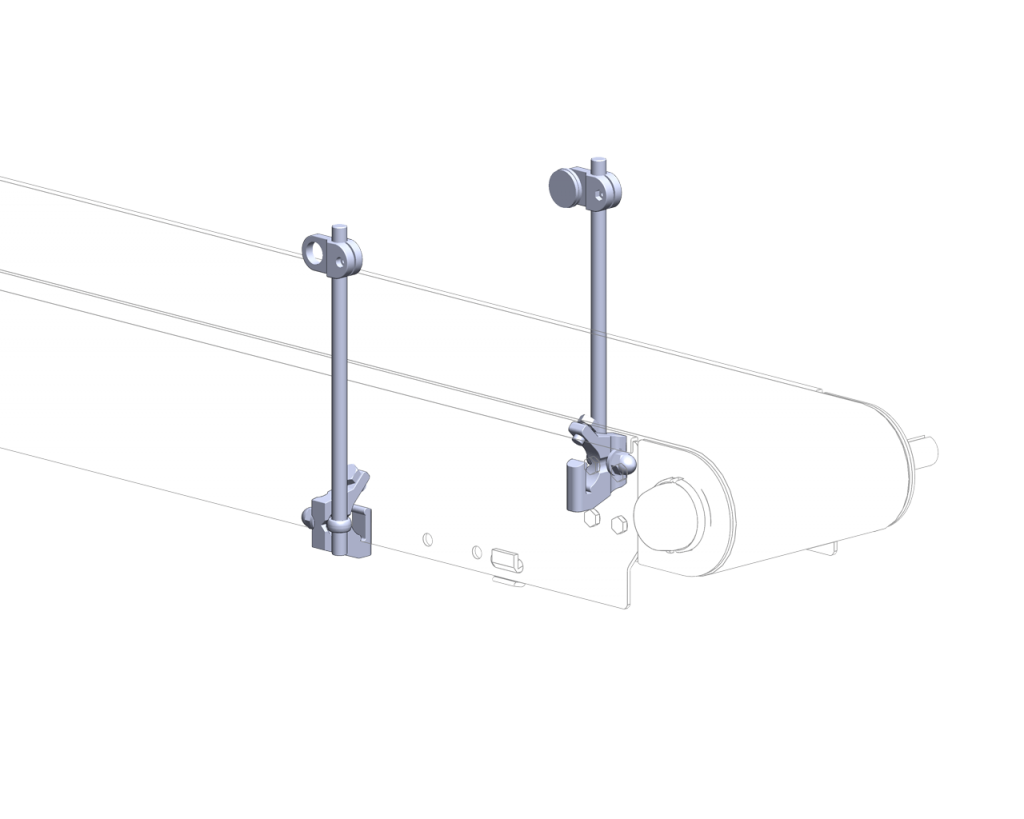

- Mit der werkzeuglosen Kipp-Riemenscheibe lässt sich das Förderbandende einfach anheben und bietet einfachen Zugang zum Innenbereich des Förderbereichs für die Reinigung.

- Das Förderband ist so konstruiert, dass es Hochdrucksprühung (100-1.500 psi) und chlorhaltigen Reinigungslösungen standhält.

- Die Rückführbandstützen sind segmentierte Gleitblöcke aus Kunststoff, die sich für die effektive Reinigung leicht ohne Werkzeuge abbauen lassen.

- Antriebskettenräder befinden sich auf einer quadratischen Edelstahlwelle (3,81 cm (1,5”)) ohne Befestigungselemente und bieten so optimale Antriebskraft und Reinigungsfähigkeit.

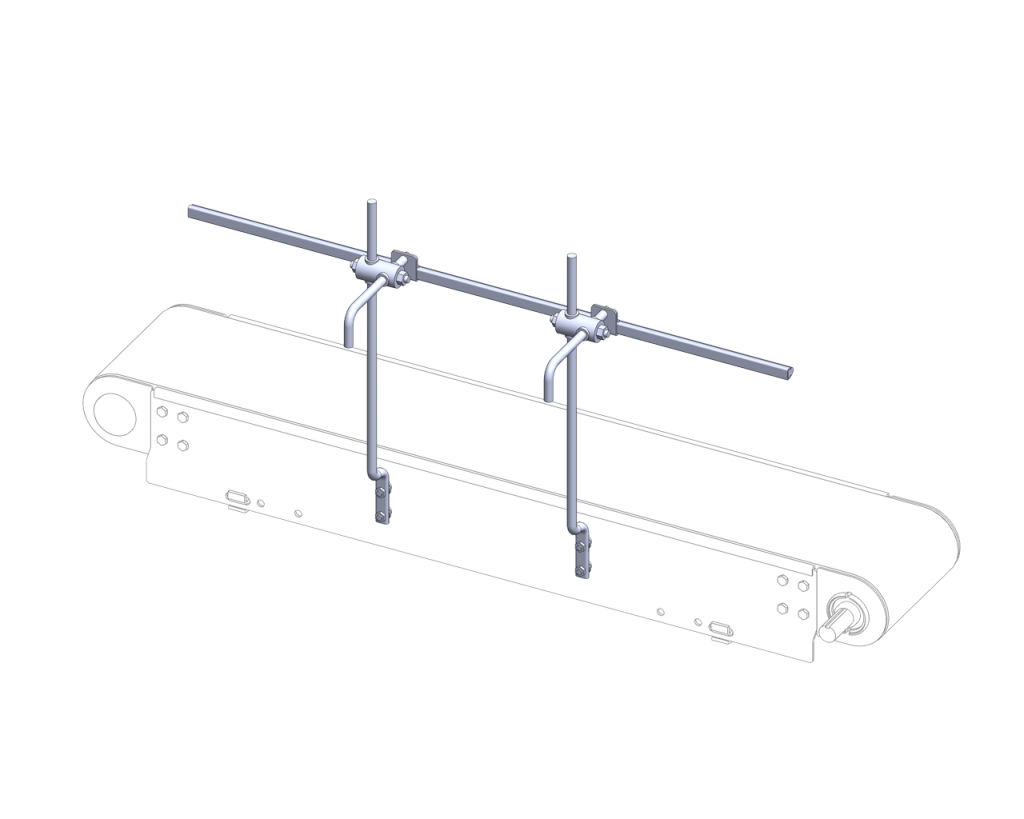

- Aussparungen am Rahmen (optional) sind verfügbar, um das Absprühen der Innenseite des Förderbands ohne Anheben des Bands zu ermöglichen.

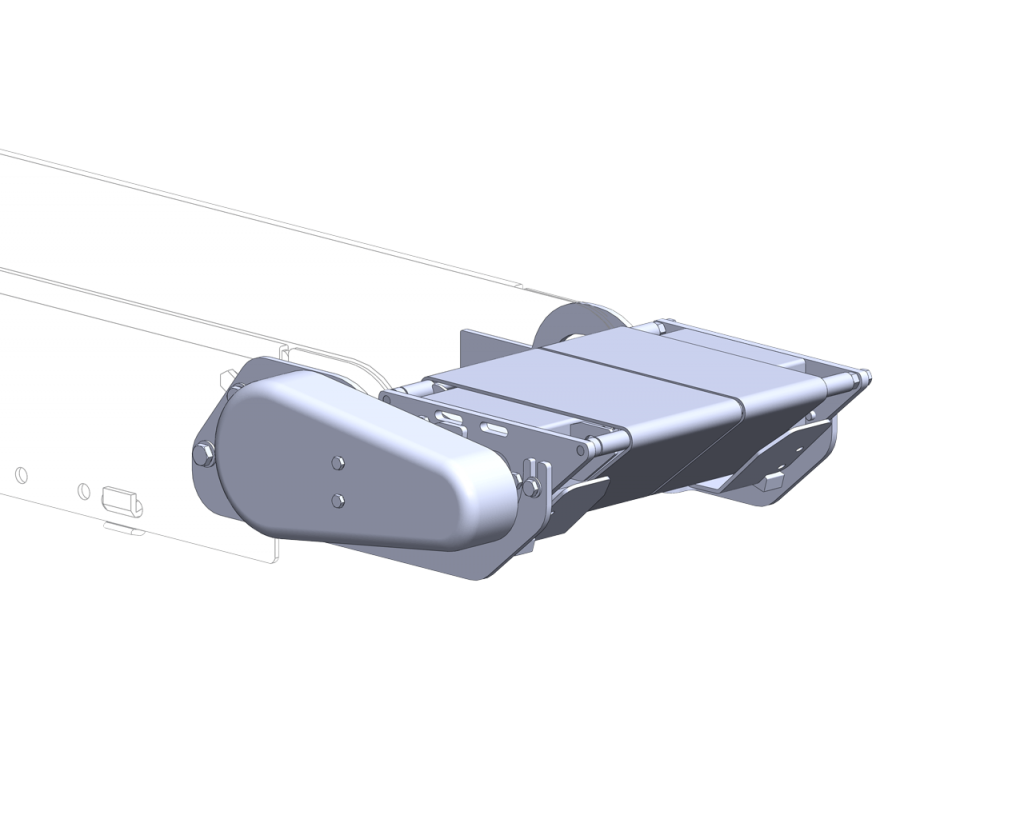

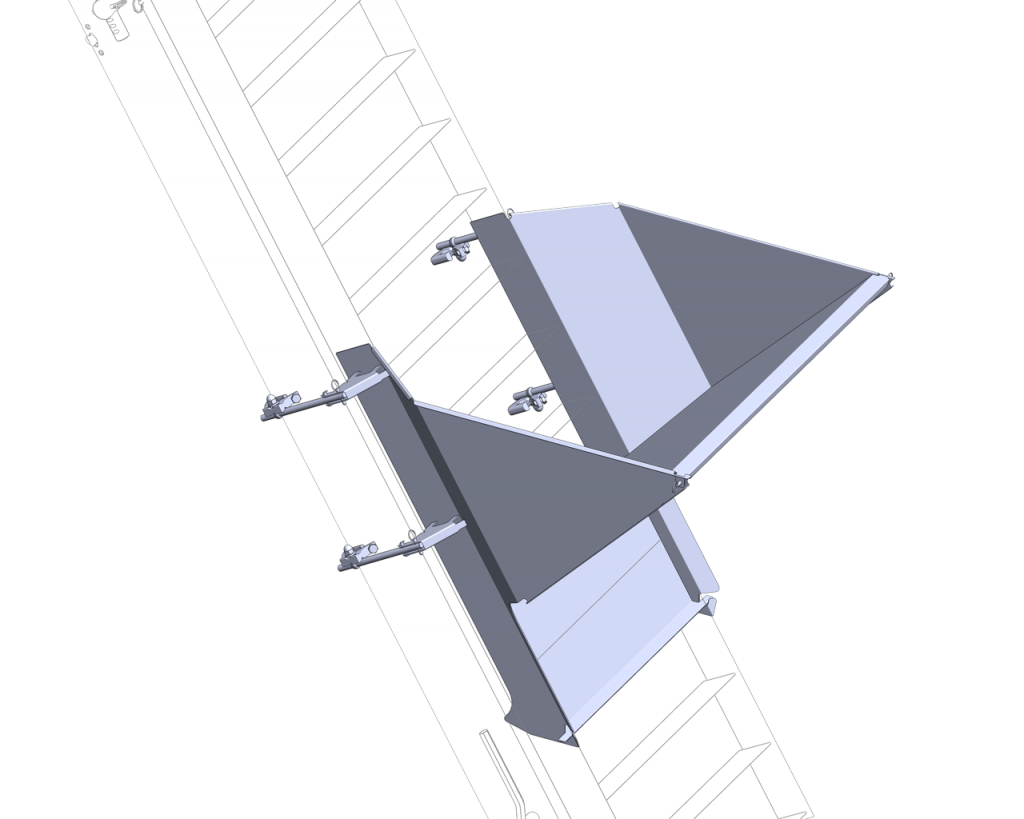

- Druckbalken-Bandradseiten (optional) sind aus einer gefrästen UHMW-Stange konstruiert und bieten einen Transfer von 3,81 cm (1,5″).

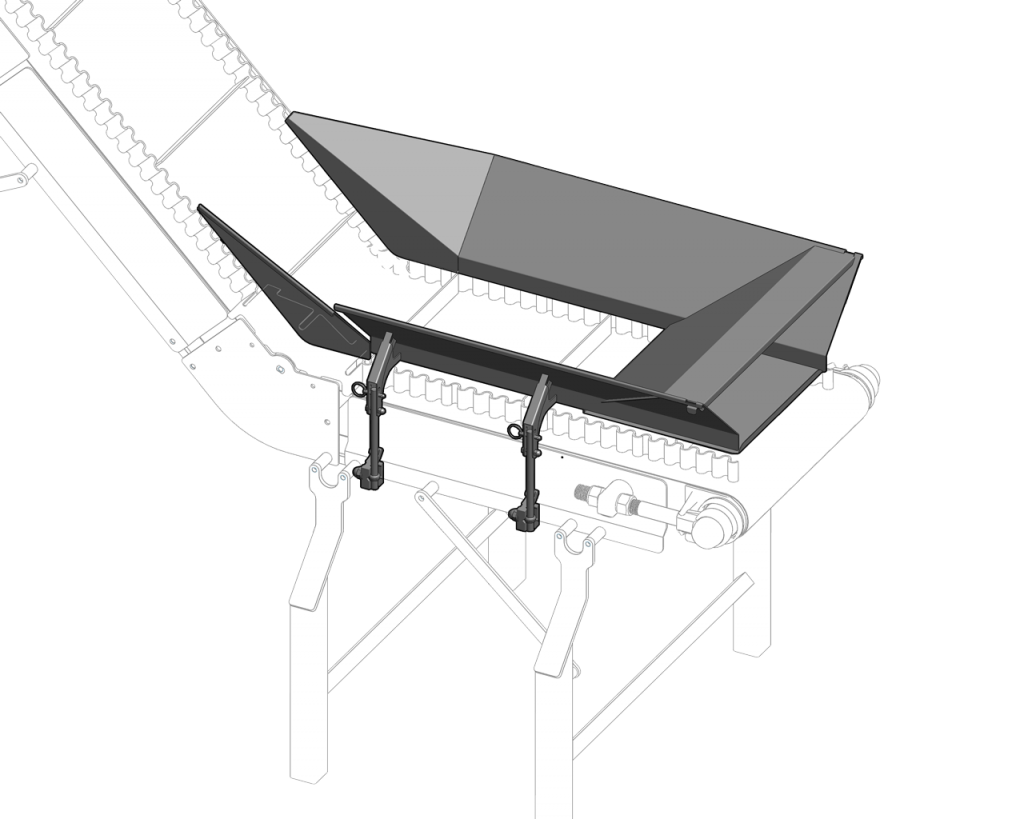

- Die Druckbalken-Antriebskonfiguration (optional) ermöglicht bei Transfers von kleinen Produkten den Einsatz von Druckbalkentransfer an jedem Förderbandende.

- Bandheber (optional) heben das Band von den Verschleißstreifen hoch; dafür einfach einen Außenhebel ziehen; für einfachen Zugang und effektive Reinigung.

Hinweis: Der Endnutzer trägt die Verantwortung für die sachgemäße Förderbandanwendung, Reinigung und Hygiene.

Bei Bedarf kann Dorner Förderbänder passivieren oder die meisten Materialien in 316 oder 316L Edelstahl liefern.

Technische Daten

- Ladung: 90 kg/m2 (20 lbs/square foot) Band

- Bandbreiten: 10,1 cm (6″) bis 91,4 cm (60″)

- Längen: 10,1 cm (36″) bis 91,4 cm (999″)

- Bandgeschwindigkeit: Maximal 71 m/min (233 ft/min)

- Verschleißstreifenmaterial UHMW

- Kontinuierlich TIG-geschweißter 304 Edelstahlrahmen

- Edelstahl-Förderbänder, die den Produktverlust reduzieren

- #4 Endschliff auf allen Außenflächen

- Lagermaterial 400 Edelstahl

- Lagerschmierstoff ist Typ H1 FDA-Schmiermittel

- FDA-zugelassene Band- und Kunststoffkomponenten

- Accessories

- Profile

- Gurte

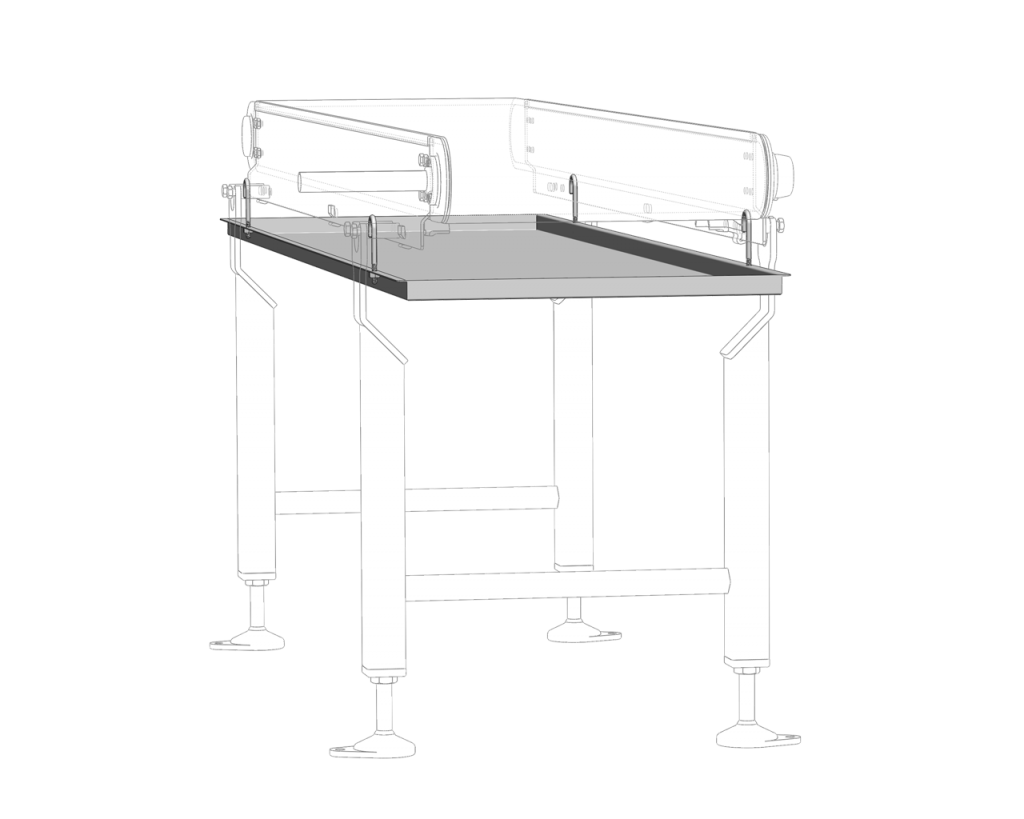

- Ständer

- Getriebemotoren

- Motor Montage Kit

- Bedienungsanleitung und Literatur

Accessories

Profile

Gurte

Ständer

Getriebemotoren

Motor Montage Kit

Bedienungsanleitung und Literatur

| Engineering Manuals | Pages | File Size |

| Sanitary Conveyors Overview | 52 | 8.14 MB |

| Literature | Pages | File Size |

| AquaPruf Conveyors Brochure | 6 | 3.15 MB |

| Sanitary Conveyors Line Card | 6 | 5.97 MB |

| AquaPruf Accessories Brochure | 3 | 402 KB |