Dorner’s ability to create the perfect solution for almost any application has been the defining factor that positioned us as… Read more »

Kategorie: Conveyor Automation

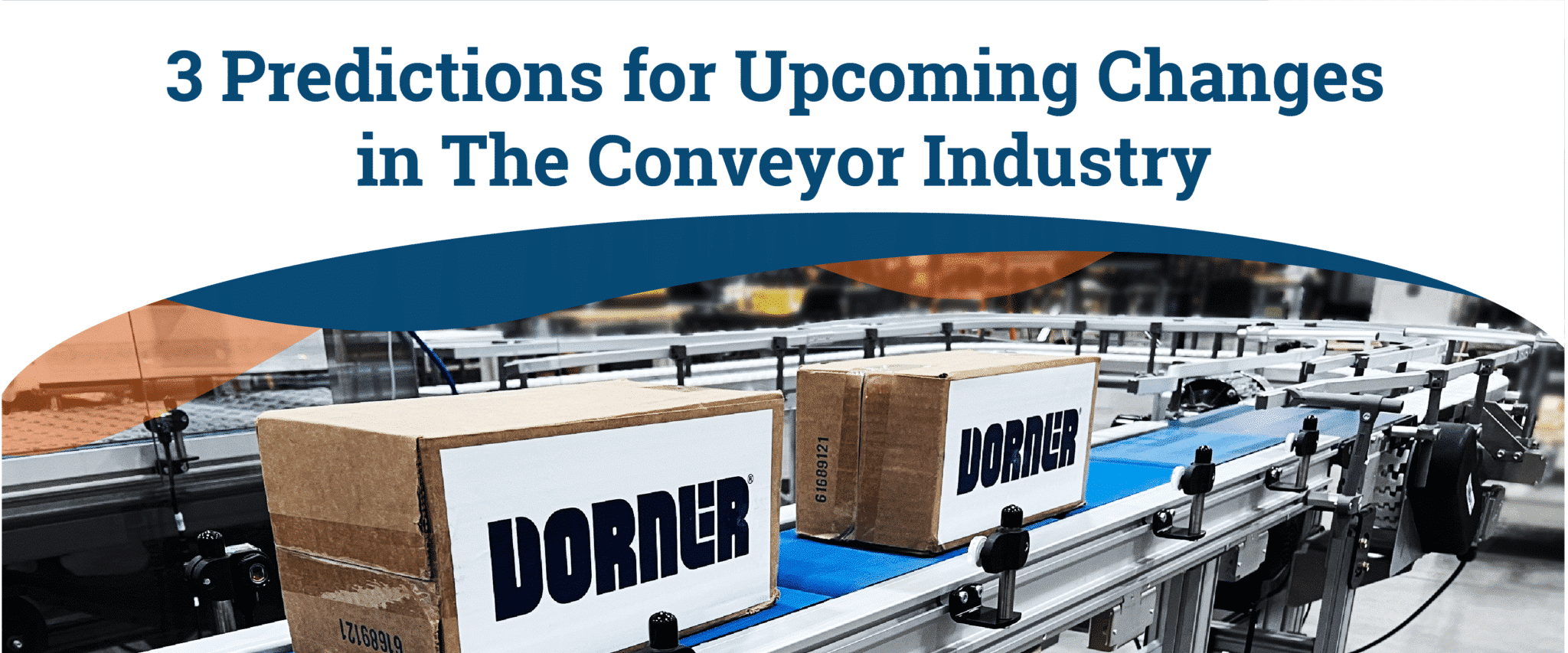

3 Predictions for Upcoming Changes in The Conveyor Industry

The conveyor industry has been a cornerstone of modern manufacturing and material handling for decades, revolutionizing production lines and streamlining… Read more »

See Our E-Commerce Conveyors in Action

The e-commerce market is fast-paced and continuously growing in demand. At Dorner, we understand the importance of ensuring the… Read more »

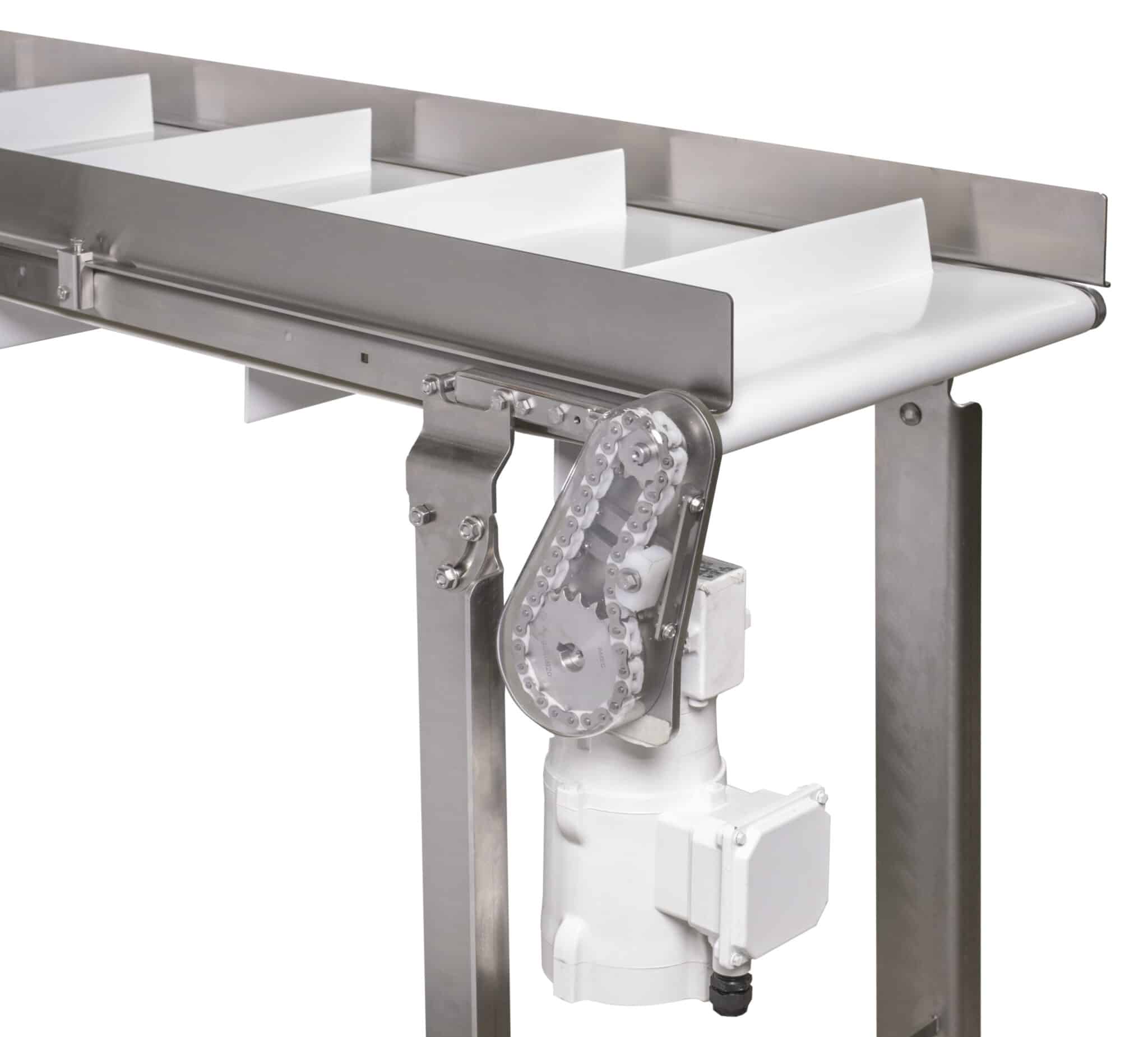

Wir stellen den AquaGard LP vor, Dorner Europes neues flaches Sanitärförderband

Das NEUE AquaGard LP Sanitärförderband Der neue AquaGard LP Förderer von Dorner Europe ist so konzipiert, dass er in… Read more »

Custom Conveyor System for Medical Devices

During the peak of the COVID-19 pandemic, automation proved to be an essential aspect of manufacturing. Many companies were… Read more »

Increasing Efficiency with Warehouse Automation

One of the biggest challenges for businesses across industries is managing their warehouse and material handling processes efficiently and accurately.… Read more »

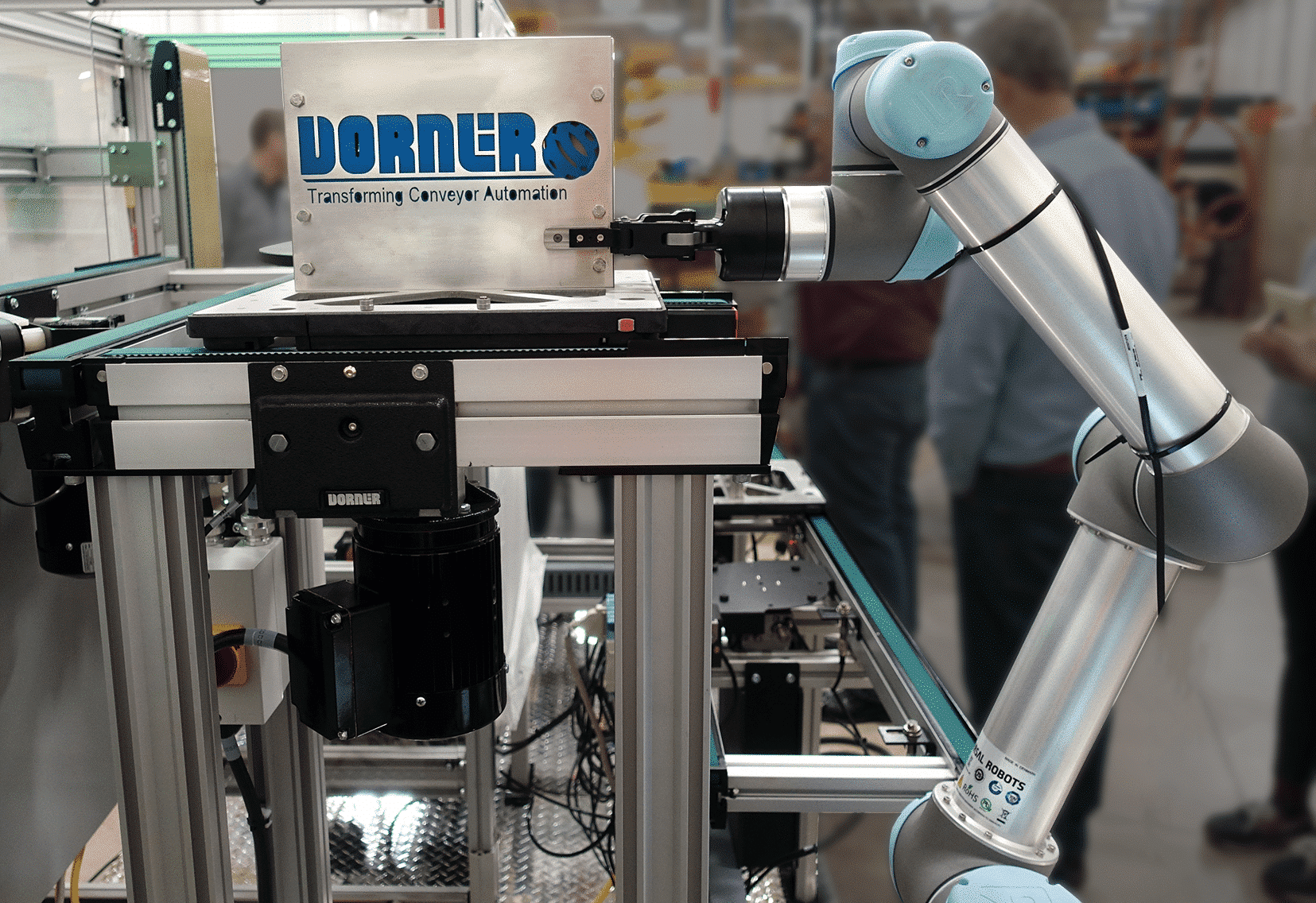

Pros and Cons of Integrating Robotics in Manufacturing

As technology continues to progress towards new innovations in automation, it is no surprise that the robotics industry is… Read more »

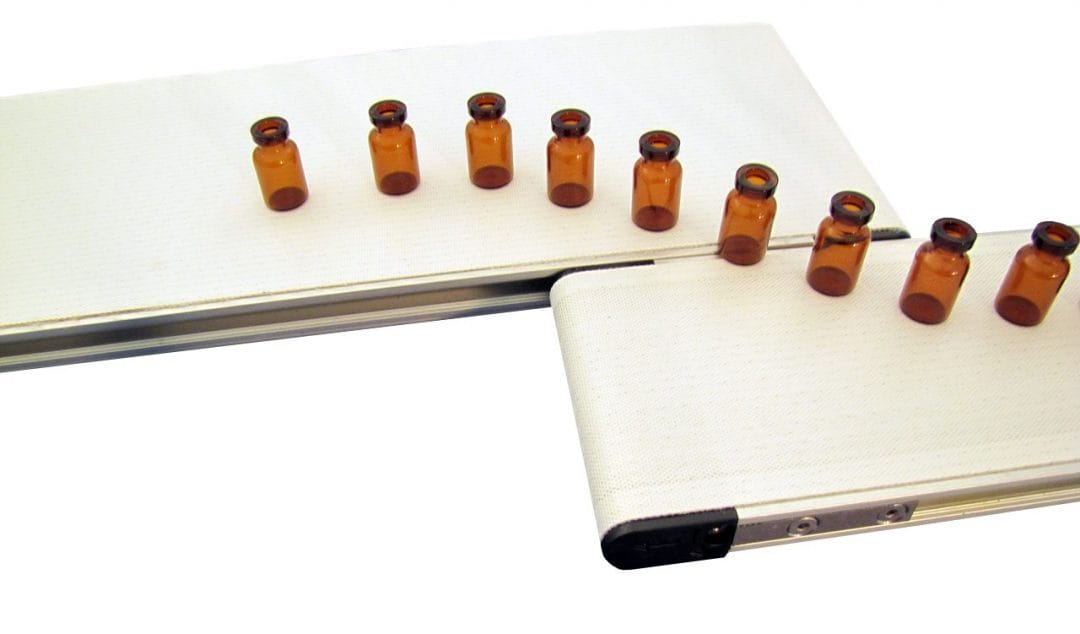

Dorner Conveyors Help to Solve Pharmaceutical Industry Challenges

The pharmaceutical industry is constantly evolving to meet new demands and patient needs, while still striving to operate as safely… Read more »

Pair Dorner Conveyors with Garvey Accumulators

Dorner partners with many organizations to bring top-of-the-line conveyance products and systems to our customers. In this new series,… Read more »

Fördersysteme mit Robotik integrieren

Dieser Artikel erschien ursprünglich in der Mai-Ausgabe 2021 der Design World.. Durch die Integration von Förderern und Robotern wurde… Read more »

Steigern Sie die Effizienz von Produktionsanlagen mit Förderbändern und automatisierten Förderlösungen

Fördersysteme sind ein wesentlicher Bestandteil jeder Produktionsanlage, verbessern die Effizienz, und senken die Kosten. Auch erhöhen sie den Arbeitsschutz… Read more »

Conveyors Are Fulfilling Key Roles in E-Commerce Applications

When it comes to both conveyors and online orders, quick delivery is king. Nowhere is that more prevalent than over… Read more »

Speed Up Your Process with Cleanroom Conveyors

Are changing demands impacting your business? Dorner’s variety of cleanroom verified conveyors* are designed to keep your products and customers… Read more »

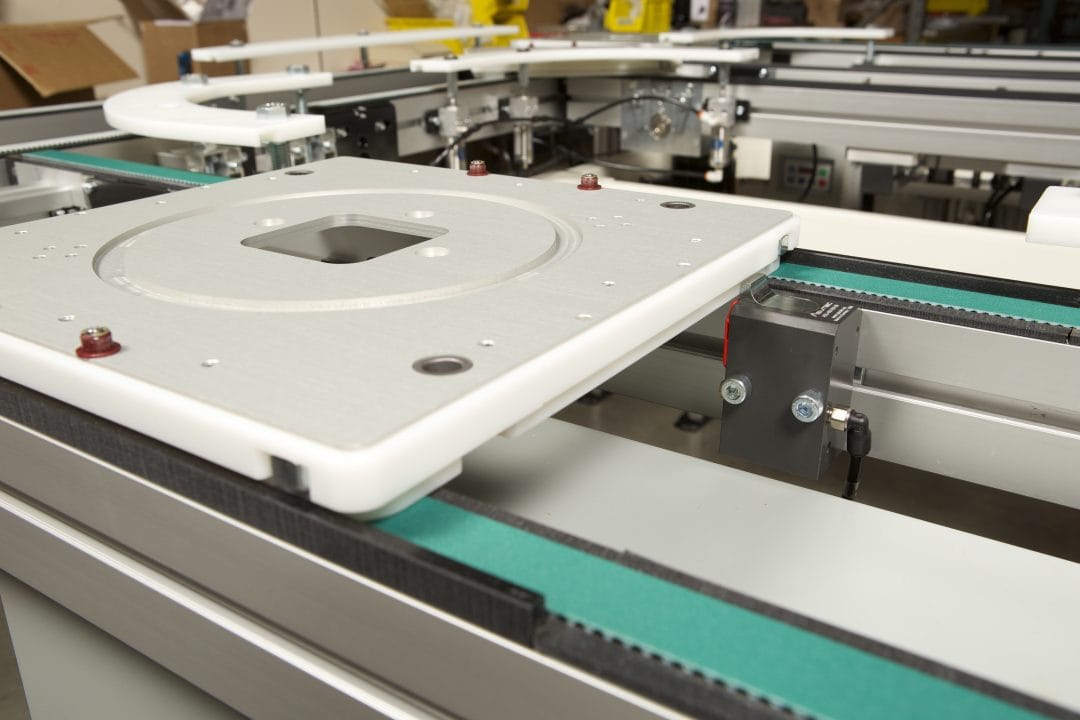

Tote System Simplifies Pharmacy Automation

Traditional pharmacies are often largely manual processes that require employees and pharmacists to carry orders around by hand. This can… Read more »

Einfache Automatisierung: mit ausfahrbaren Förderbändern von Dorner

Durch eine Einziehfunktion, die das Ende eines Förderbandes aus- und einfährt, erreichen Förderbänder eine hohe Funktionalität. Wahlweise manuell oder… Read more »

Sehen Sie Dorners Förderband-Transfers in Aktion

Die branchenführenden Transfers von Dorner wurden entwickelt, um Ihr Produkt effizient zu bewegen und gleichzeitig Produktverluste zu vermeiden. Ganz… Read more »

Mit Automatisierung wettbewerbsfähig bleiben

Von John Kuhnz, Vizepräsident – Engineered Solutions Die Erhöhung der Geschwindigkeit ihrer Verpackungslinie ist eine der häufigsten Anfragen, die wir… Read more »

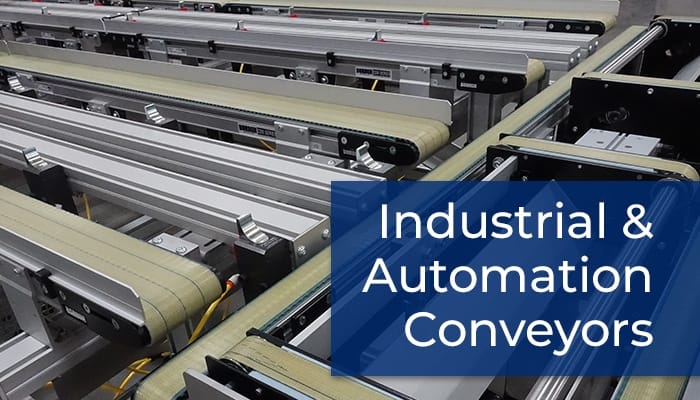

Dorner Has Your Material Handling Needs Covered

Dorner’s Material Handling Conveyors are designed to handle all stages of the manufacturing process, from production and assembly through… Read more »

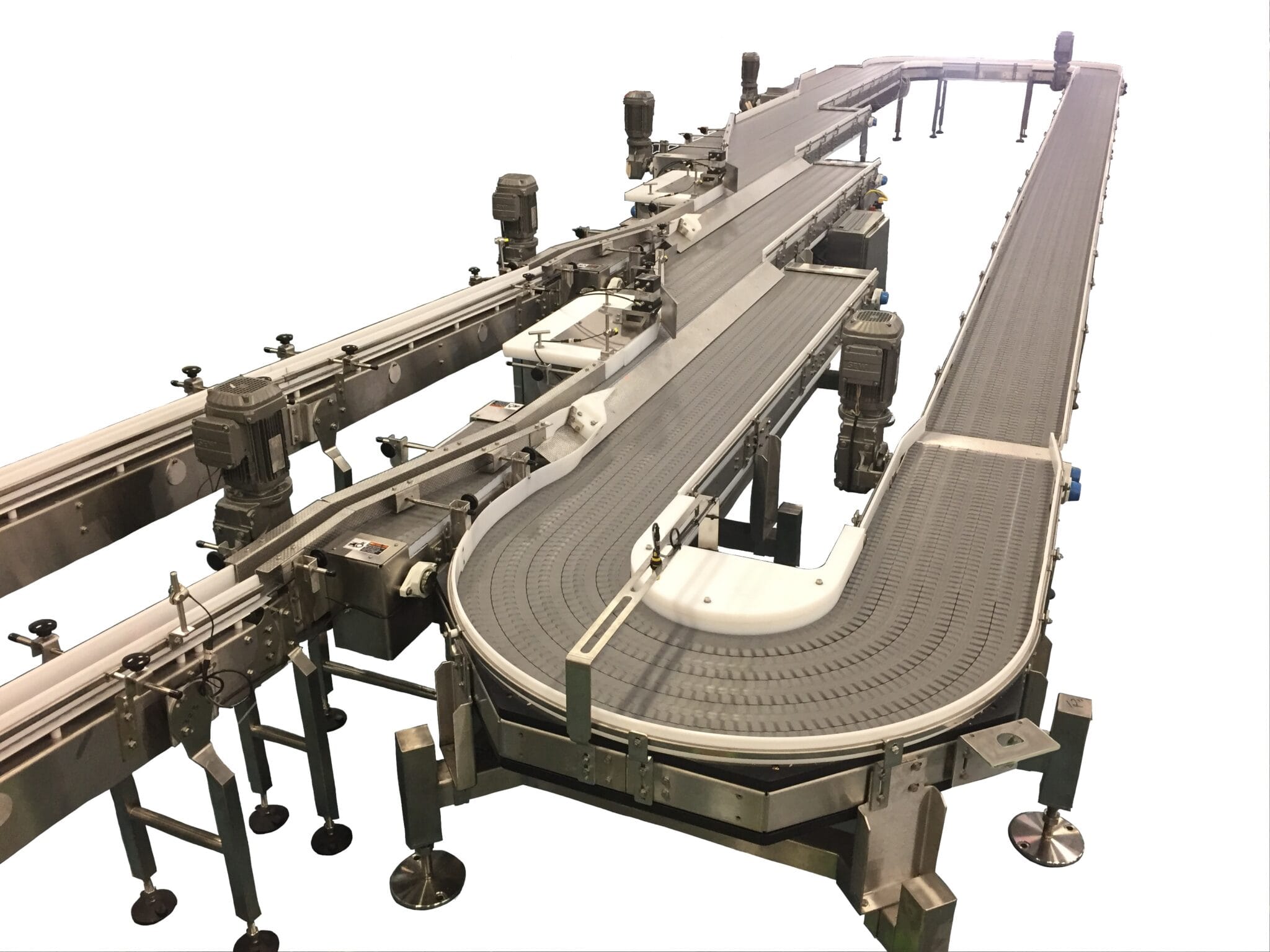

Case Handling System using 3200 Series Conveyors with Intralox ARB Technology

In a recent application, a customer needed a flexible system that could handle many different sizes and patterns of… Read more »

Increase Throughput and Efficiency with a Tote Handling System

See this system in action at the end of the post! Recently, a pharmaceutical company came to Dorner looking for… Read more »

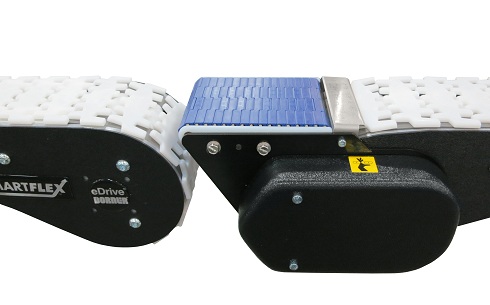

Lift Gate Provides Added Flexibility to SmartFlex System

Dorner’s 2200 Series SmartFlex conveyors are one of our most flexible systems available. For this application, the customer was… Read more »

Vertical Precision Move Conveyor for Elevation Changes in Manufacturing Line

Manufacturing lines aren’t always on a single level. For this paper company, the product accumulator was 20 feet above the… Read more »

Reducing Product Loss

When you need to move product from one conveyor to another that’s often where challenges arise. You could just put… Read more »

Belt or Chain, Belt vs. Chain – Not Really

What makes a belt better than a chain and vice versa? The answer is nothing. Belts are no better than… Read more »