The e-commerce market is fast-paced and continuously growing in demand. At Dorner, we understand the importance of ensuring the… Read more »

Kategorie: Belt Conveyors

3 Ways Conveyors Can Support E-Commerce Success

(This blog was originally posted on Packaging Digest) The pandemic lifestyle has dramatically changed how people work, socialize, and purchase products. For… Read more »

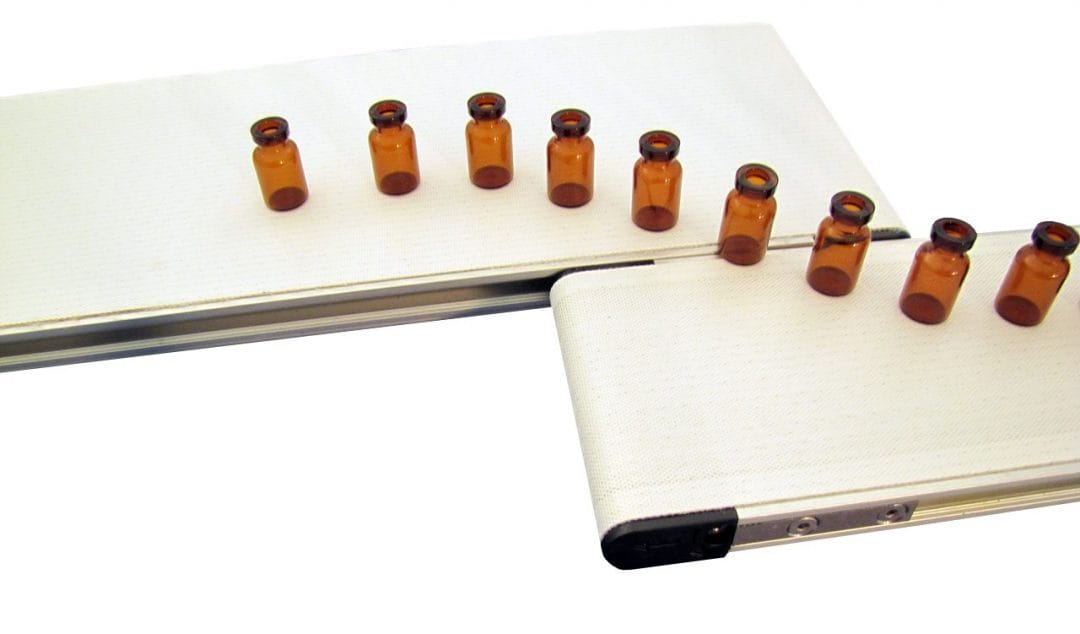

Dorners Minis: die Klein-Förderer für jede Anwendung

Trotz ihres kompakten platzsparenden Maßes sind Klein-Förderer ebenso funktional wie alle anderen Förderer von Dorner. Besonders beliebt sind sie in… Read more »

Große Auswahl an kleinen Förderbändern

Dorner bietet eine große Auswahl an kleinen Förderbändern, die für den Transport von Teilen und Produkten aller Größen, Formen und… Read more »

Speed Up Your Process with Cleanroom Conveyors

Are changing demands impacting your business? Dorner’s variety of cleanroom verified conveyors* are designed to keep your products and customers… Read more »

3200 Series Precision Move Conveyors for Guaranteed Accuracy

Dorner’s 3200 Series Line of Conveyors are heavy duty, low maintenance conveyors designed for medium to large sized part handling.… Read more »

Kundenspezifische Vakuumförderer aus eigener Fertigung

Wenn Ihre Produkte oder Komponenten klein und leicht sind und sich mit konstanter Geschwindigkeit bewegen, benötigen Sie eine Transferlösung,… Read more »

Seamless Integration Powered by Precision Move Platform

Recently, a Dorner customer was in the position of needing to automate a product labeling line. The line presented… Read more »