In manufacturing, the cost per square foot of a facility is a metric that is constantly scrutinized. As throughput targets increase, the natural reaction is to add more machinery. However, walls do not move. This leads to the “crowded floor” dilemma, where forklift aisles narrow, maintenance access becomes restricted, and safety zones are compromised.

The instinct might be to expand the building, but that comes with significant costs and is often not even a possibility. The ideal solution is to reclaim the vertical space — the “air rights” of the factory — and to optimize the geometry of material flow.

Space-saving conveyor technologies are designed specifically to manipulate product flow in three dimensions, allowing engineers to decouple throughput from floor area.

This article explores the mechanics and applications of specific space-saving configurations, including spirals, alpines, wedges, and vertical elevators.

The Vertical Buffer: The Alpine Conveyor

Accumulation is a vital aspect of large-scale production lines. If the downstream case packer jams, the upstream filler cannot stop immediately without ruining product or causing complex restart procedures.

You need a buffer zone.

Traditionally, this was achieved with massive mulit-conveyor accumulation tables or long runs of serpentine conveyors, both of which consume significant amounts of floor space.

The Dorner FlexMove Alpine Conveyor addresses this by stacking the accumulation path vertically. Ideally suited for flexible packaging, bottles, or small cartons, the Alpine acts as a vertical parking garage. The conveyor belt spirals up a central column and then spirals back down (or outputs at the top).

By utilizing the vertical axis, an Alpine system can provide hundreds of feet of buffer capability in a footprint as small as 4×4 feet. Mechanically, this system uses a flexible plastic chain with friction inserts to ensure product stability on the incline.

The impact on integration is profound. Instead of dedicating an entire bay to accumulation tables, a facility can place an Alpine unit directly above or next to a machine. When the downstream machine faults, the Alpine switches to “storage mode,” filling the vertical layers. When the machine clears, the Alpine empties. This maintains the “continuous run” efficiency of the primary equipment without expanding the line’s linear footprint.

Continuous Vertical Elevation: Spiral Conveyors

Moving product between floor levels (such as from a production floor to a mezzanine packing area) often dictates the layout of the entire line. Standard incline belt conveyors are limited by the coefficient of friction. Generally, you cannot incline a standard belt more than 15 to 18 degrees before the product slips. To raise a product 10 feet at an 18-degree angle requires over 30 feet of linear floor space.

Spiral Conveyors (specifically the FlexMove Helix) eliminate this linear requirement. By winding the conveyor path in a tight corkscrew, the Helix achieves the same elevation change in a roughly 5-foot diameter.

Unlike reciprocating elevators that move one load at a time, spirals offer continuous flow. There is no indexing, stopping, or starting. This is critical for high-speed lines where throughput cannot be throttled by the elevation mechanism.

The engineering behind the Helix involves specialized chain designs that reduce friction on the inner radius. In standard curves, the chain wants to pull tight against the inside rail, creating drag and wear. The Dorner Helix utilizes patented side-roller chains or low-friction slat designs to mitigate this, allowing for high speeds and heavy loads without motor burnout or chain stretching. This allows the spiral to be placed effectively anywhere — over an aisle, in a corner, or directly feeding a palletizer.

High-Speed Vertical Indexing: The Wedge Conveyor

For rigid packaging — cans, bottles, tissue boxes, plastic containers — the Wedge Conveyor offers the most aggressive space savings for vertical transfer. The concept is simple but effective: two parallel conveyor tracks face each other, pinching the product from the sides.

Because the product is gripped securely, it can be moved vertically at 90 degrees, straight up or straight down. This results in a virtually zero-footprint transfer. The conveyor takes up only slightly more space than the product itself.

The Wedge is particularly valuable in creating “over-under” line layouts. For example, empty cartons can be transported on an overhead conveyor to keep the floor clear. When they reach the filling station, a Wedge conveyor brings them straight down to the operator’s level. Once filled, another Wedge can take them back up for overhead transport to the sealer.

Dorner’s wedge elevators feature rapid width adjustment mechanisms. A hand-crank or automated servo adjustment opens and closes the gap between the tracks, allowing the line to switch from 12oz bottles to 2-liter bottles in minutes. This flexibility makes the Wedge a viable option for high-mix contract packagers who need to maximize every inch of floor space.

90-Degree Transfers and Pop-Ups

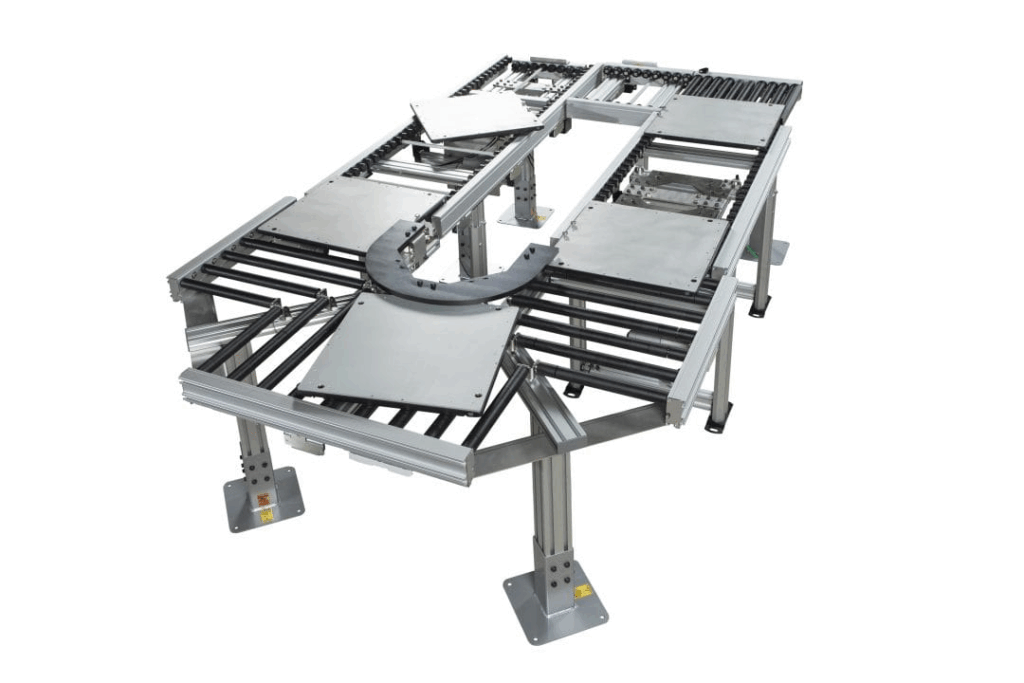

Space is often lost at the corners. In a traditional pallet handling system, turning a corner requires a large radius turn or a turntable, both of which have significant footprints and safety guarding requirements.

Dorner’s ERT (Edge Roller Technology) conveyors utilize a different approach for pallet handling. The ERT 250 uses rollers driven by a linear gearbox shaft to move pallets. To turn a corner, the system uses a “pop-up” transfer module. The pallet stops, and a perpendicular set of rollers or chains pops up within the frame of the conveyor to lift the pallet and move it 90 degrees.

This transfer happens inside the footprint of the conveyor frame. There is no external radius, no swinging arm, and no protruding motor. This allows for tight grid layouts. You can create a matrix of assembly stations where pallets move in a square loop with zero wasted space on the turns. For cleanrooms or assembly cells where floor space costs are premium, this internal transfer capability is a significant asset.

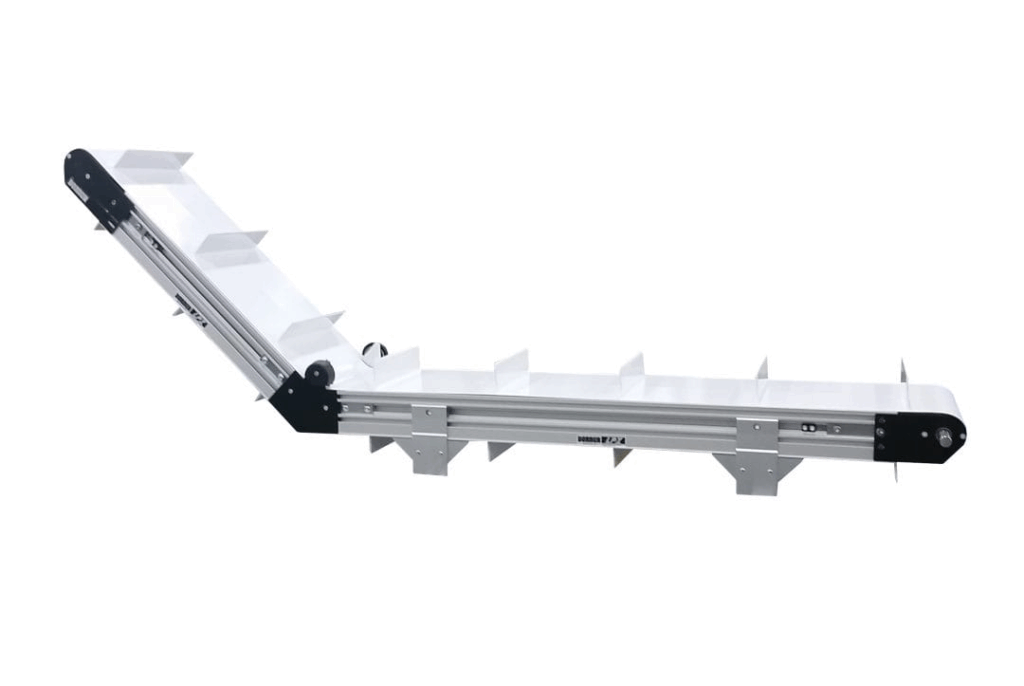

Navigating Obstacles: The Z-Frame

Not all space-saving is about vertical storage; sometimes it is about obstacle avoidance. Structural columns, electrical panels, and walkways often force production lines into inefficient, winding paths.

Z-Frame Conveyors (like the Dorner 2200 LPZ) allow the conveyor to change elevation abruptly to clear these obstacles. The “Z” shape allows the conveyor to go from a horizontal load height, up an incline (often with cleated belts to prevent slip), and back to horizontal to discharge over an aisle or into a hopper.

The engineering advantage of the Z-frame over multiple separate conveyors is the single drive. One motor drives the entire belt path. This eliminates the need for two extra motors and electrical drops that would be required if you used three separate conveyors (horizontal-incline-horizontal) to do the same job. Fewer motors mean less cabling, less energy consumption, and less panel space required, contributing to an overall leaner, more compact installation.

Optimizing A Crowded Production Floor

Instead of viewing the floor plan as a 2D puzzle, engineers must leverage the 3D capabilities of modern conveyance.

By deploying Alpine buffers to utilize ceiling height, Helix spirals for continuous elevation, Wedge elevators for rapid vertical transfer, and Z-frames to navigate obstacles, facility managers can significantly increase the density of their production capabilities.

These technologies, core to Dorner’s portfolio, transform the conveyor from a simple transport device into a strategic tool for spatial management, allowing businesses to scale operations without the capital expense of facility expansion.