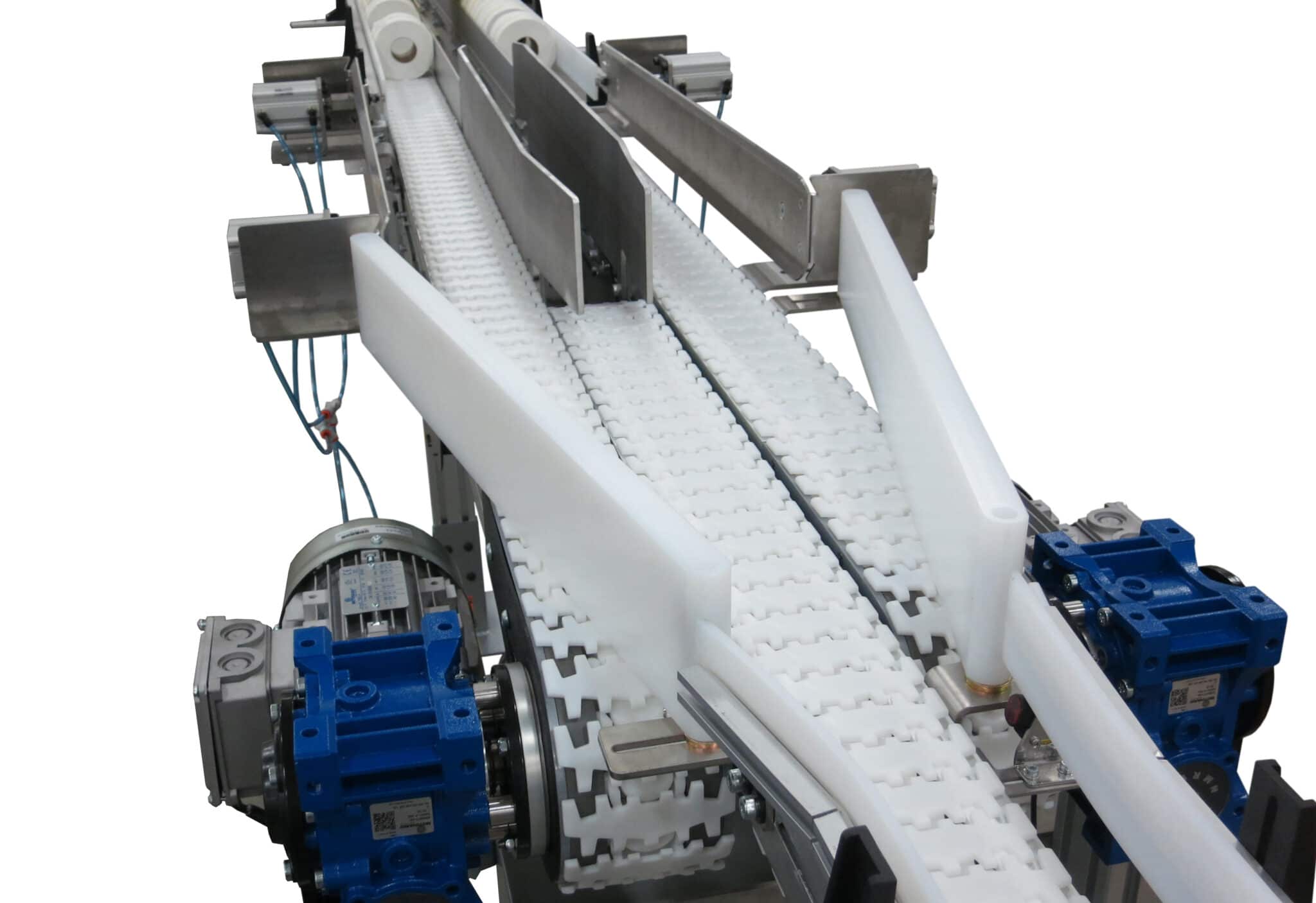

We are happy to announce some new features to our FlexMove flexible chain conveyance solution. These additions further the complete offering that this product offers to users. Dorner has introduced inline transfers, pop up stops, and a side guide bending unit that will enhance the versatility and functionality of FlexMove.

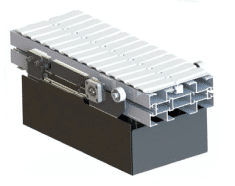

Inline transfers

S Transfers

- S In-Line Modules provide a standard, compact way to side transfer product from conveyor to conveyor.

- Straight guiding is placed across the transfer module for smooth In-Line product flow

- Conveyors are mounted together to provide a smooth transfer even for small products

- S In-Line transfers are compact in the width dimension

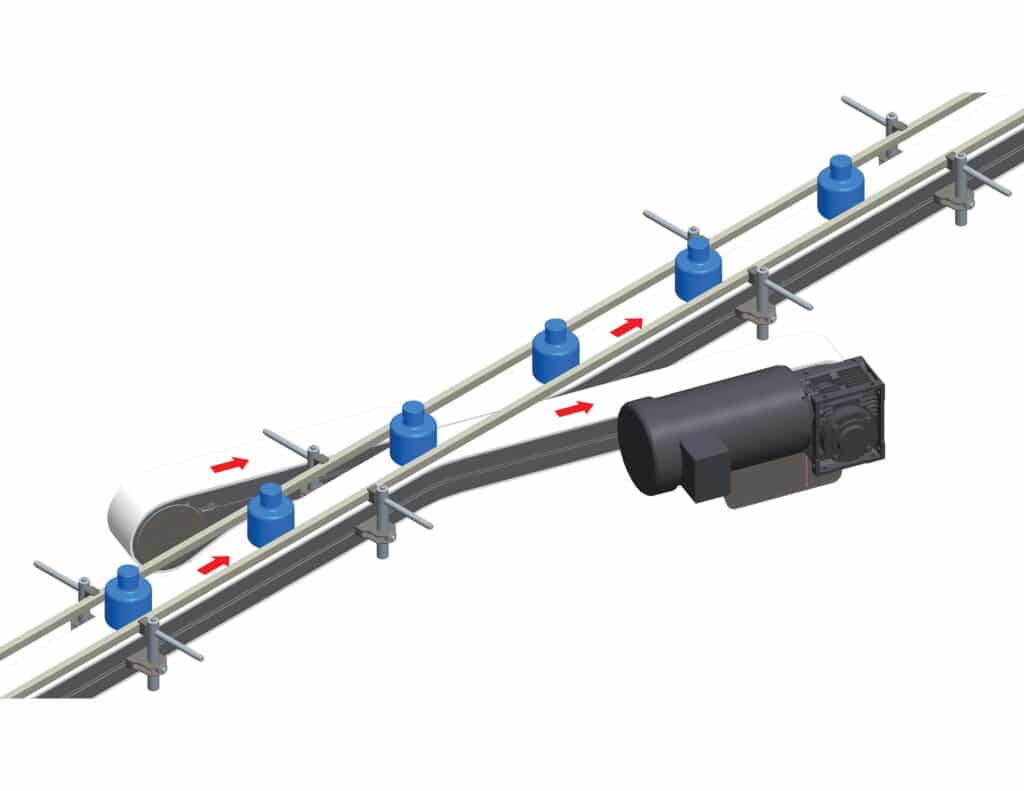

X Transfers

- X In-Line Modules provide a standard, compact way to side transfer product from conveyor to conveyor.

- Straight guiding is placed across the transfer module for smooth In-Line product flow

- Conveyors are mounted together to provide a smooth transfer even for small products

- X In-Line transfers are compact in the length direction

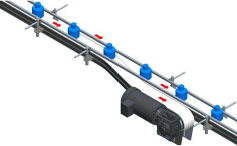

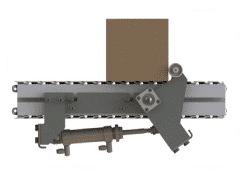

Pop-Up Stop

The pop-up stop unit was developed to stop product movement for products that are wider than the conveyor width.

Features

- Supported accumulation load: Up to 60kg.

- Maximum conveyor speed: up to 40m/min.

- Available for conveyor width: 45mm, 65mm, 85mm,105mm,150mm,180mm & 260mm.

- Best work with FlexMove plain chain.

- Using pneumatic system.

- Can be used as product spacer.

- Can be operate without sensor.

- Low maintenance.

Specifications

- Ø6mm tubing speed controller

- Operating air pressure range: 0.5~0.6MPa

- Air consumption: 0.01m3 per minute

- (Calculation based on tubing length of 1.5m & Number of cycles of 180 times per hour)

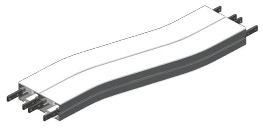

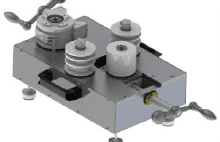

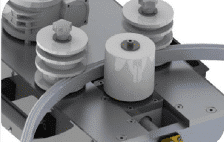

Side Guiding Bending Unit

Introducing the go-to companion for on-site installation and modification tasks – our Manual Side Guide Bending Unit. Engineered for the convenience of professionals on the move, this compact tool is designed to make your bending tasks easier and more efficient during on-site projects.

Features

- Portability: A compact and lightweight design ensures effortless transport to any worksite, saving time and effort.

- On-Site Flexibility: Tailored for on-site side guide installation and modification tasks, eliminating the need for costly off-site bending.

- Approximate Angle Bending: Designed for quick and convenient angle without the need for precision tools.

- User-Friendly Operation: Intuitive controls and ergonomic design make bending rail angles a breeze for all skill levels.

- Time-Efficient: Reduces downtime during installation and maintenance, increasing overall project efficiency.

Specifications & Dimension

- Operating Mechanism: Manual hand crank

- Sizes: 256 mm x 690 mm x 254 mm (W)x(L)x(H)

- Weight: 28kg Material Compatibility: FGRR-10×20 and FGRR-15×20

For a comprehensive overview of our entire FlexMove offering please visit the webpage here.