- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

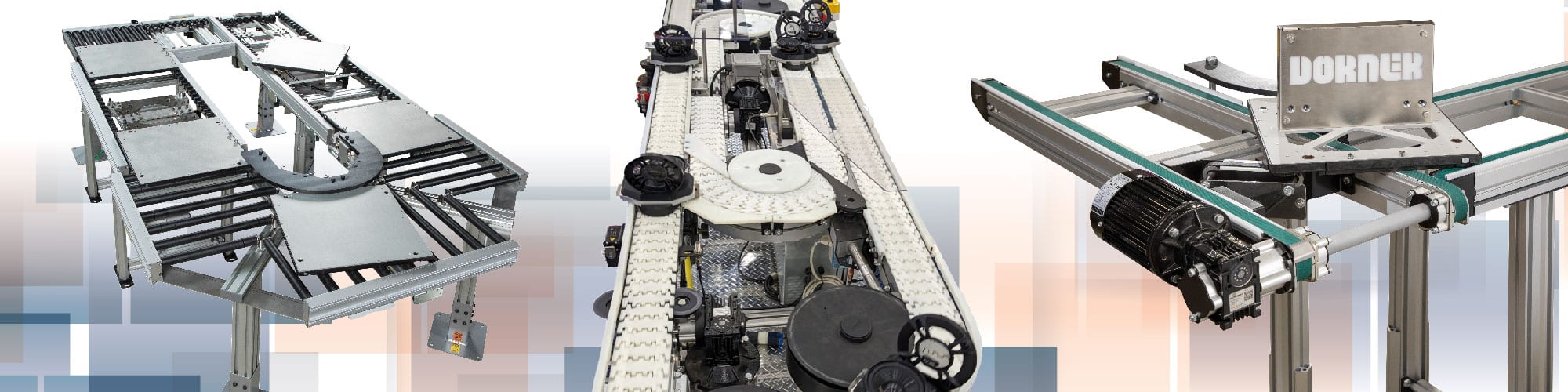

Pallet Systems

Features & Benefits

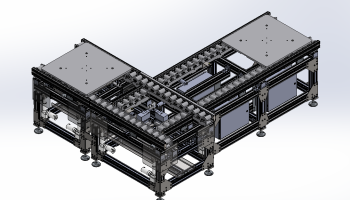

Dorner’s Pallet System conveyors simplify product flow and control with features such as a unique pin tracking system, industry-compatible pallet sizes, and innovative modules. All of our pallet system conveyors are modular and easy to customize to fit almost any application.

We offer a variety of pallet systems including timing belt, flexible chain, and edge roller technology designs. Each system offers advanced pallet traffic management and is specifically designed to increase efficiency, reduce downtime in automation processes, and provide accurate product placement.

Features

- Our most accurate product placement and positioning conveyors

- Industry-leading product routing and control

- Integration with robotics and automated processes

- Low-profile design

- Wide variety of modules for easy customization

- Customizable pallet size options available

Benefits

- Accurate positioning and routing

- Ideal for assembly processes or inspection

- Pin tracking system – simple and cost-effective method of tracking pallets through turns

- Pallets can be purchased as completed assemblies or as kits

- Rated for various cleanroom applications

Pallet System Product Lines

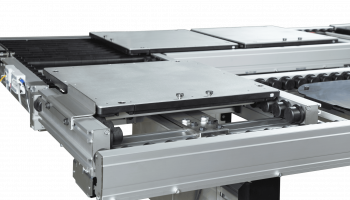

Dual timing belt conveyor system offers highly accurate product positioning within ± 0.5 mm, and is perfect for automated production operations.

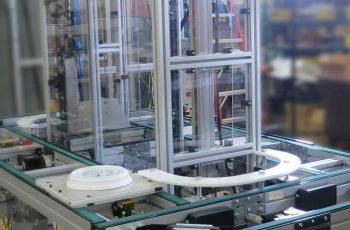

Utilizing edge roller technology (ERT), the clean, open-frame design is ideal for electronics assembly, pharmaceutical processing, and more.

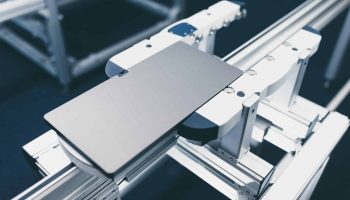

Flexible chain pallet system is a highly customizable solution for lightweight product assembly, routing, and inspection.

Industries & Applications

Pallet conveyor systems offer a unique solution for numerous applications, such as automated manufacturing, inspection and testing, product routing and flow, and robotics integration. Dorner’s pallet systems are designed to be highly customizable and easily reconfigured in the field, meaning this investment can grow and adapt to your operation.

Pallet systems are ideal for:

- Automated manufacturing

- Electronics assembly

- Medical device manufacturing

- Cleanroom applications

- Machine integration

- Material handling

- Packaging

- Pharmaceuticals

Automation

Integrators

Material Handling

Packaging

Medical

Pharmaceutical

Conveyor Insights

Dorner Solves Assembly Automation Challenges in the Automotive Industry

Dorner’s DualMove helped this tier 2 automotive manufacturer increase throughput and quality in their wiring harness operation.

Edge Roller Technology – The Ideal Solution for Cleanroom Applications

The belt-free, open-frame design of Dorner’s ERT Pallet Conveyors makes them the perfect option for Class 4 cleanroom applications.

ERT Pallet Systems Provide Simple Reconfiguration in the Field

With the patent-pending gearbox of our roller-driven conveyors, ERT conveyors maximize flexibility and productivity.

Contact the Conveyor Experts!

Our team is standing by to answer any questions you may have and help you improve your production line with a pallet system conveyor system.

Ready for a New Pallet Conveyor System?

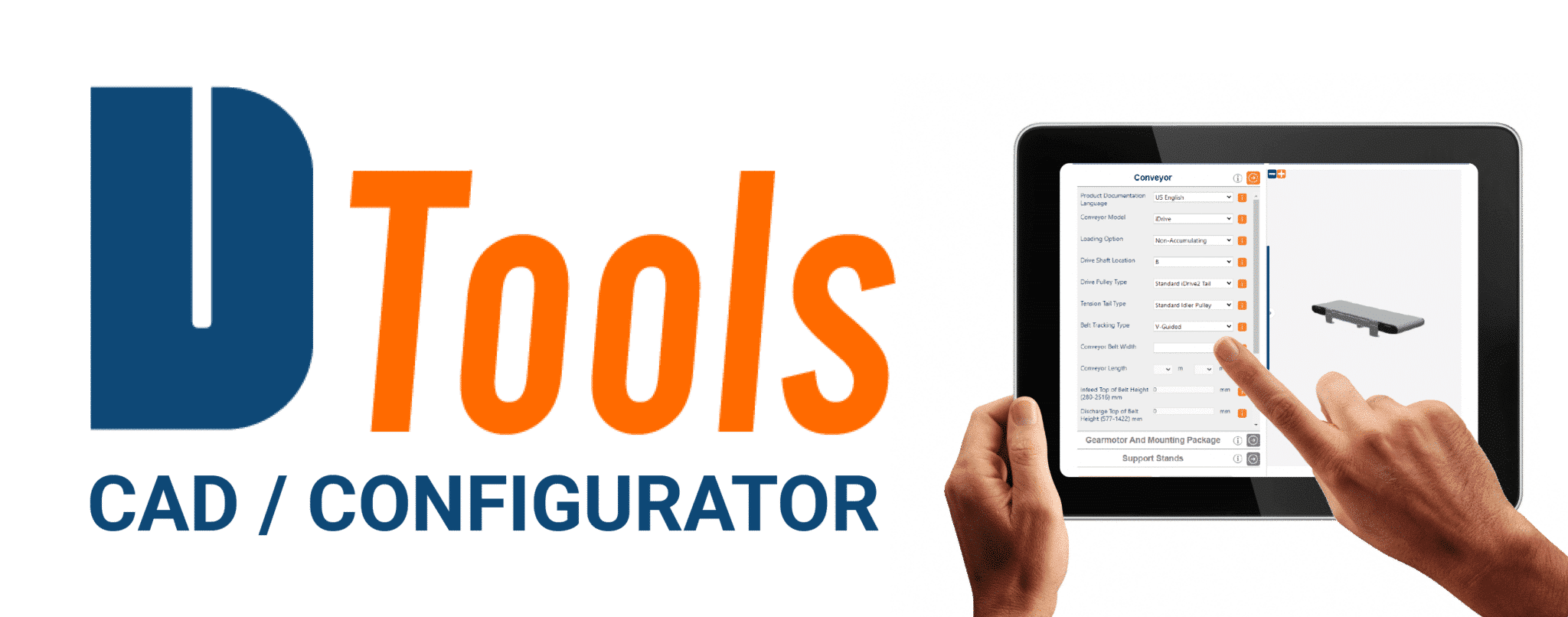

Sign up for DTools to start configuring your custom conveyor.

OR

Contact us for a no-obligations quote!

Create your own custom conveyor with Dorner’s industry-leading CAD/Configurator software. With DTools, designing a conveyor that meets your specific application is quick and easy. Submit a request for complete custom systems or replacement parts for your existing conveyor, and get a free quote and CAD design fast!

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy