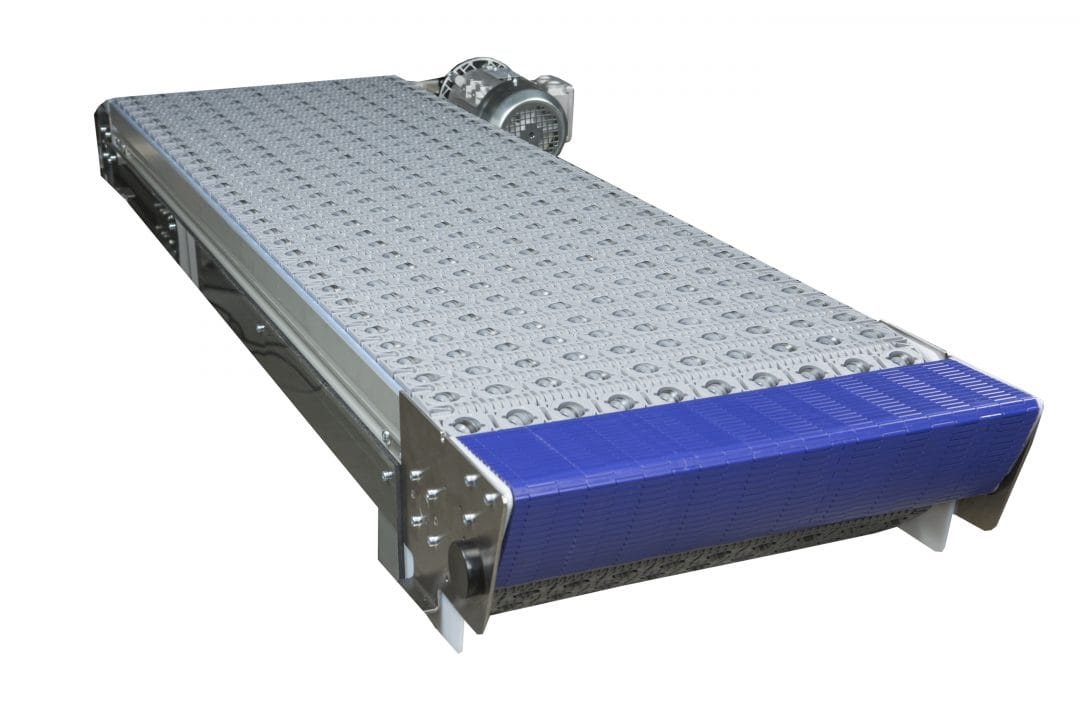

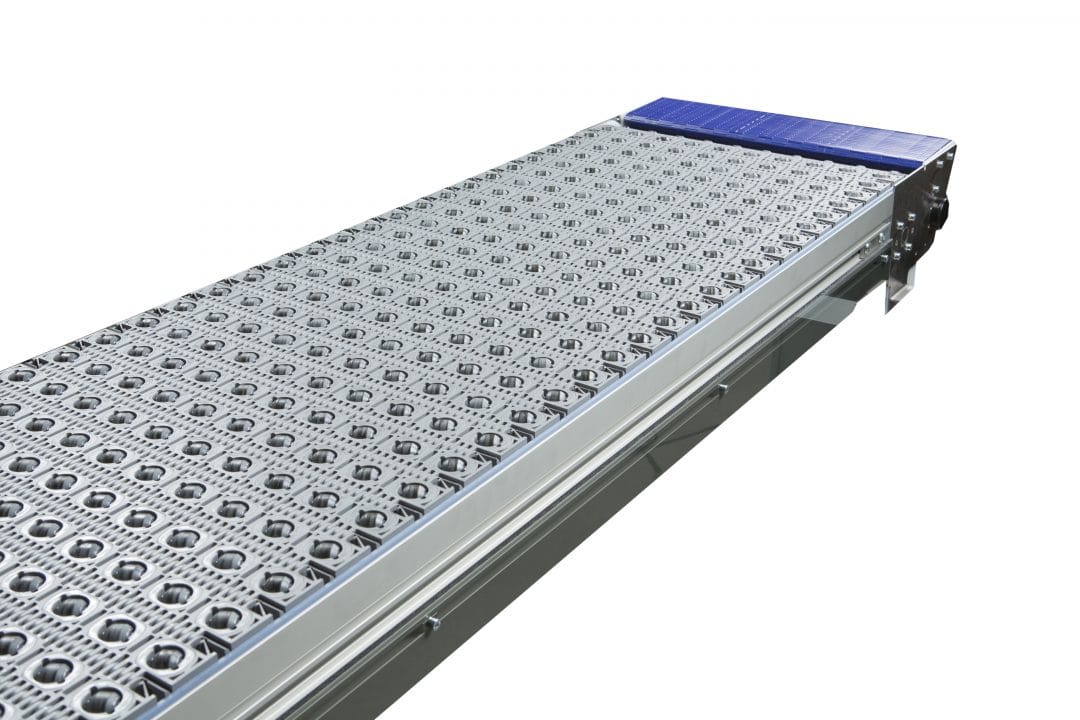

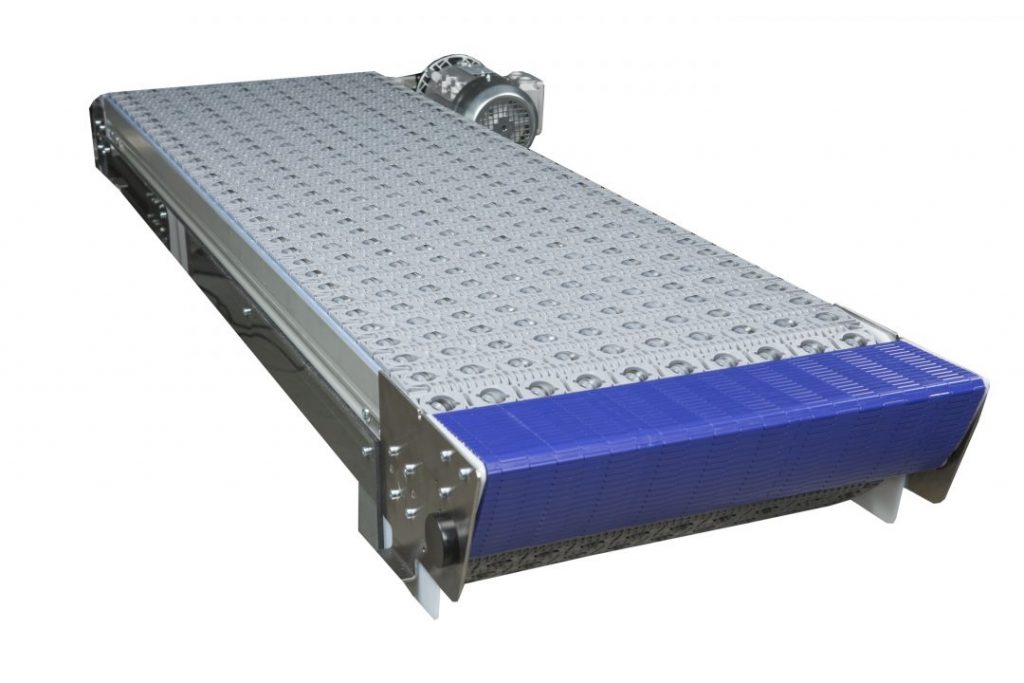

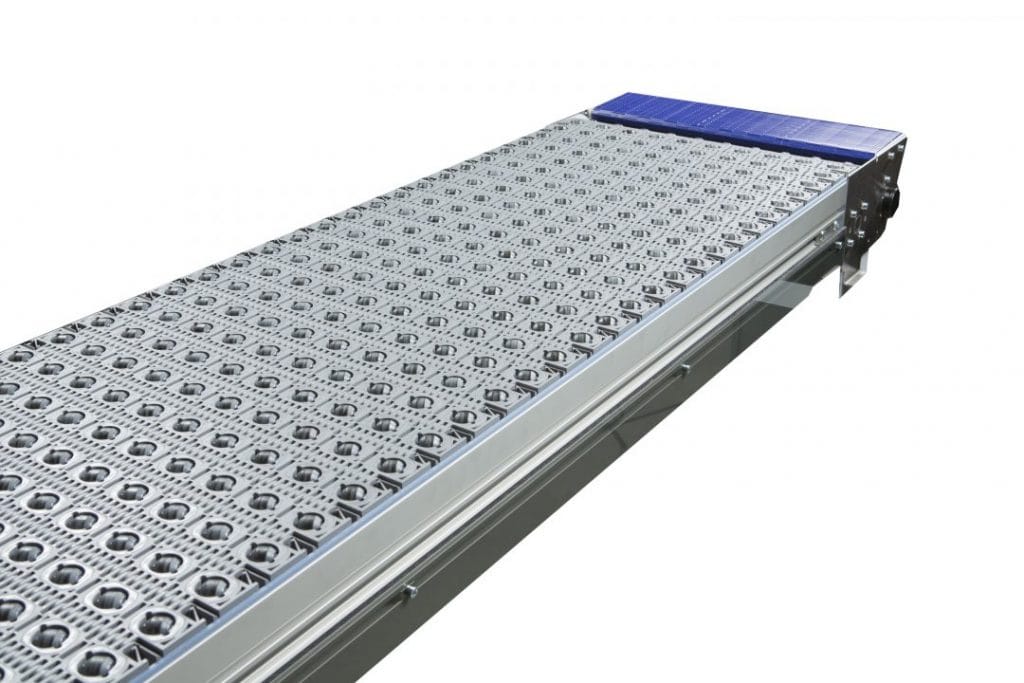

3200 Series Conveyors with Intralox Activated Roller Belt™ (ARB) Technology

3200 Series Conveyors with Intralox Modular Belting Technology

The 3200 Series Conveyors with Intralox ARB Technology use innovative conveyance technology for merging, diverting, and aligning of product.

Benefits of Using ARB Conveyors

Adding an ARB conveyor into your line can improve the flexibility, efficiency, and accuracy of your operations. Additional benefits of integrating ARB conveyor solutions include:

- Flexibility to handle multiple product sizes without the need for changeover

- Minimizes floor space consumption

- Increased system reliability

- Eliminates costly system controls, reducing complexity

- Encased moving parts provide safer work environments

- Low maintenance solution

- Handles product as small as 6″ x 6″

What to Know About Integrating Intralox Conveyors into Your Line

With an extended belt life, improved belt alignment, and a modular design that makes replacing parts time- and cost-effective, an Intralox conveyor belt can prove to be a worthwhile investment for virtually any material handling or production operation.

A 3200 series conveyor with Intralox belting may have the following features:

Specifications

- 2″ pitch ARB Chain

- Built on Dorner 3200 Series platform

- Widths: 8″ (203 mm) to 60″ (1524 mm) in 2″ (51 mm) increments

- Lengths: Minimum 3 ft (914 mm)

- Speeds: Up to 150 ft/min (46 m/min)

- Optional powered transfer

Solutions

- 90 degree transfers maintaining product orientation

- Aligners / edge justification

- Case turners

- Bump turns

- Touchless low friction merges

- Rejects

Options & Accessories

- Standard support stands and guiding options are available

- All standard 3200 Series mounting packages and gearmotors are available

90° Transfers and Lane Merges

- 90° Passive On and 90° Passive Off transfers

- No adjustment needed for different size products

- Requires 6″ – 8″ gap upstream

- 90° Passive On requires some product momentum, 90° Passive Off does not

- Using Passive On, product can merge into a gap on the mainline ARB

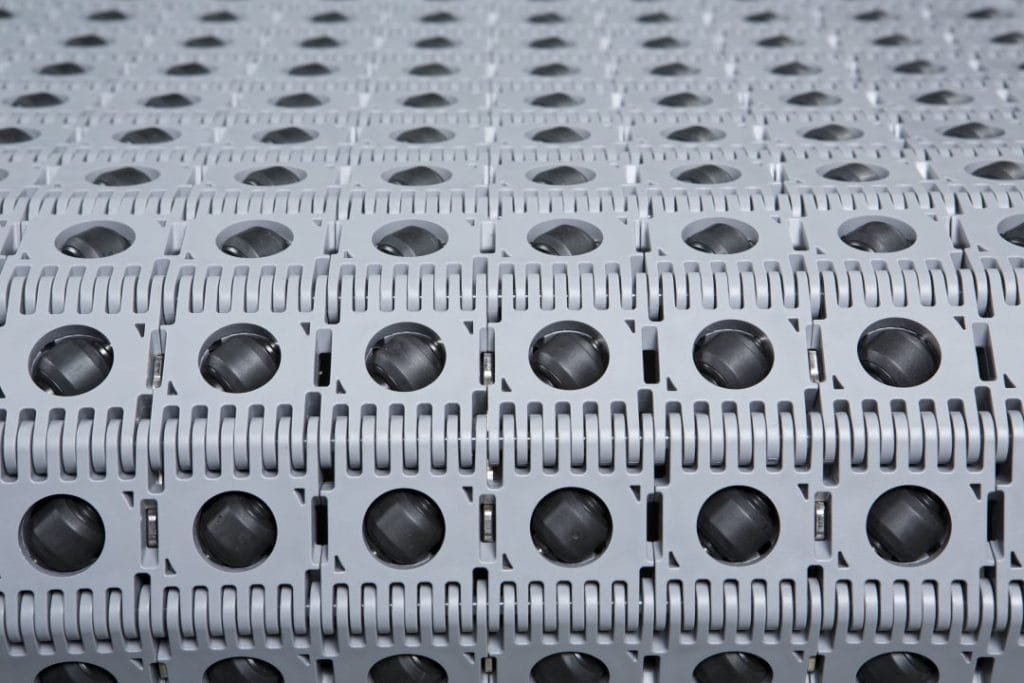

- Uses Series 400 45° Chain and Passive Rollers

Edge Justification and Bump Turns

- No adjustment needed for different size products

- Edge justification requires no product gap

- Bump turn needs 6″ – 8″ gap upstream

- A fixed or pneumatically controlled protrusion from the side rail is added to help start the turning process

- Uses Series 400 30° Chain and Activated Rollers

What Is Activated Roller Belt Technology?

Patented by Intralox, activated roller belt (ARB) technology keeps products and packages aligned while in motion without the use of rails, reducing the need for human interference or correction and thereby cutting equipment and labor costs.

How Does an Activated Roller Belt Work?

Using friction and Intralox sprockets, an ARB conveyor is able to engage the belt’s rollers for improvements in efficiency and control. The use of innovative ARB technology also allows for:

- More flexibility

- Simplified controls

- Gentler material handling

- Footprint reduction

- Efficient sorting

- Reliable merging

- Higher throughput

Common Industrial Applications of the Intralox Conveyor

Using an Intralox belt can be a wise, cost-effective decision in a number of industries and across various applications. An Intralox sorter with ARB technology, for example, may be especially productive in a facility that handles a large number of packages. Similarly, an Intralox roller belt could be useful for applications that require high conveying speeds.

While the applications of a 3200 Series Conveyor with Intralox ARB technology are varied, some of the most common uses for this system include:

- Meat processing

- Poultry processing

- Seafood processing

- Packaging

- General food handling

- Baking and confectionary

- E-commerce sorting and distribution

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| 3200 Series Engineering Manual | 108 | 11.68 MB |

| Literature | Pages | File Size |

| 3200 Series Conveyors with Intralox Activated Roller Belt (ARB) Technology | 2 | 2.48 MB |

| 3200 Series Brochure | 2 | 1.72 MB |