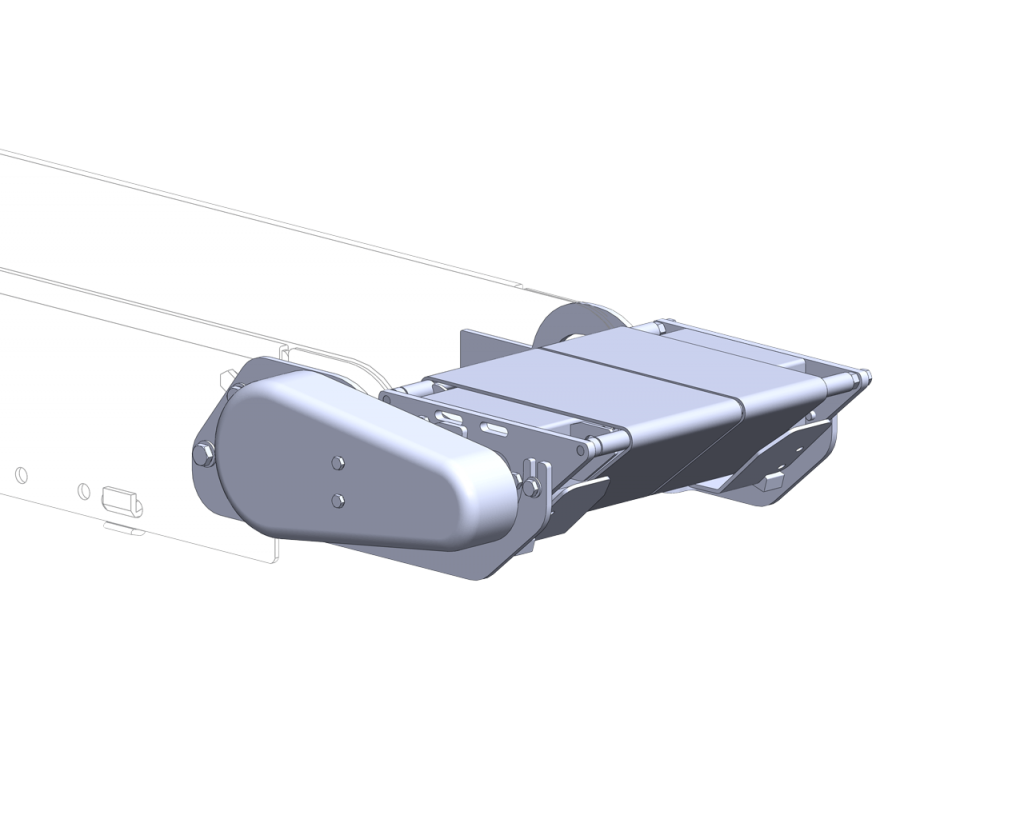

Motorized Pulley

Contact Us

Conveyor specialists are ready to help you find the right solution

Benefits of 7600 Ultimate AquaPruf Motorized Pulley:

Specifications

- Motorized Pulley Widths: 12” to 46” in 2” increments

- All external components are stainless steel

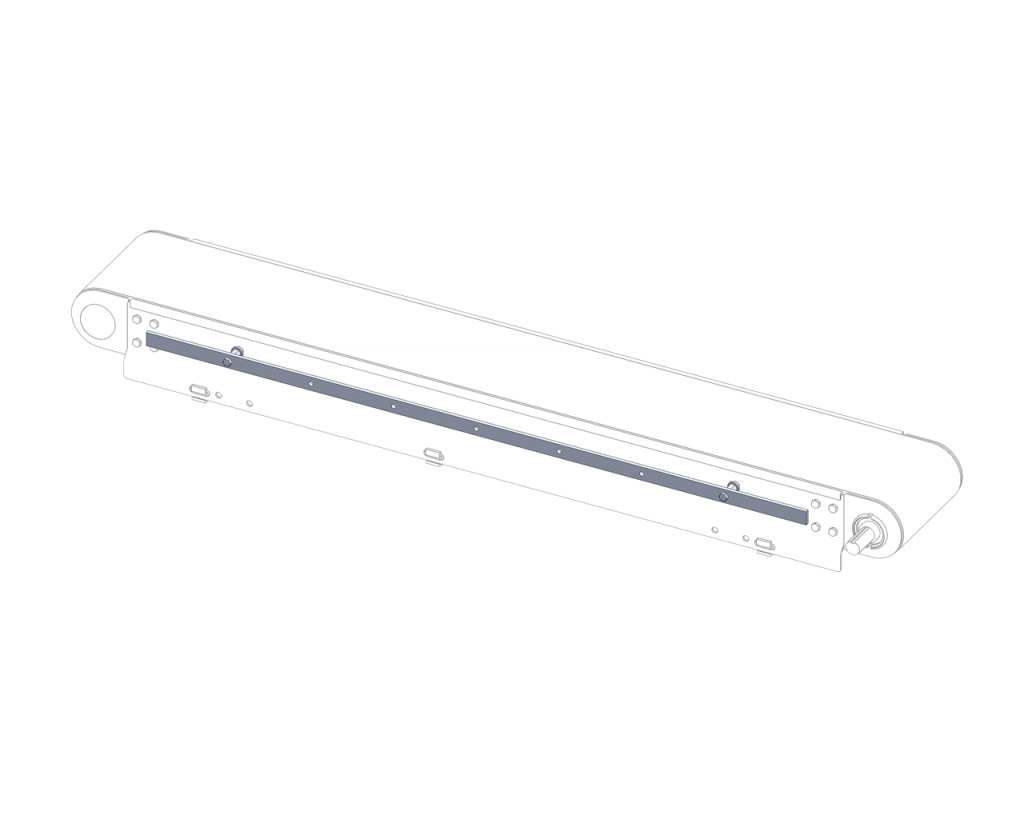

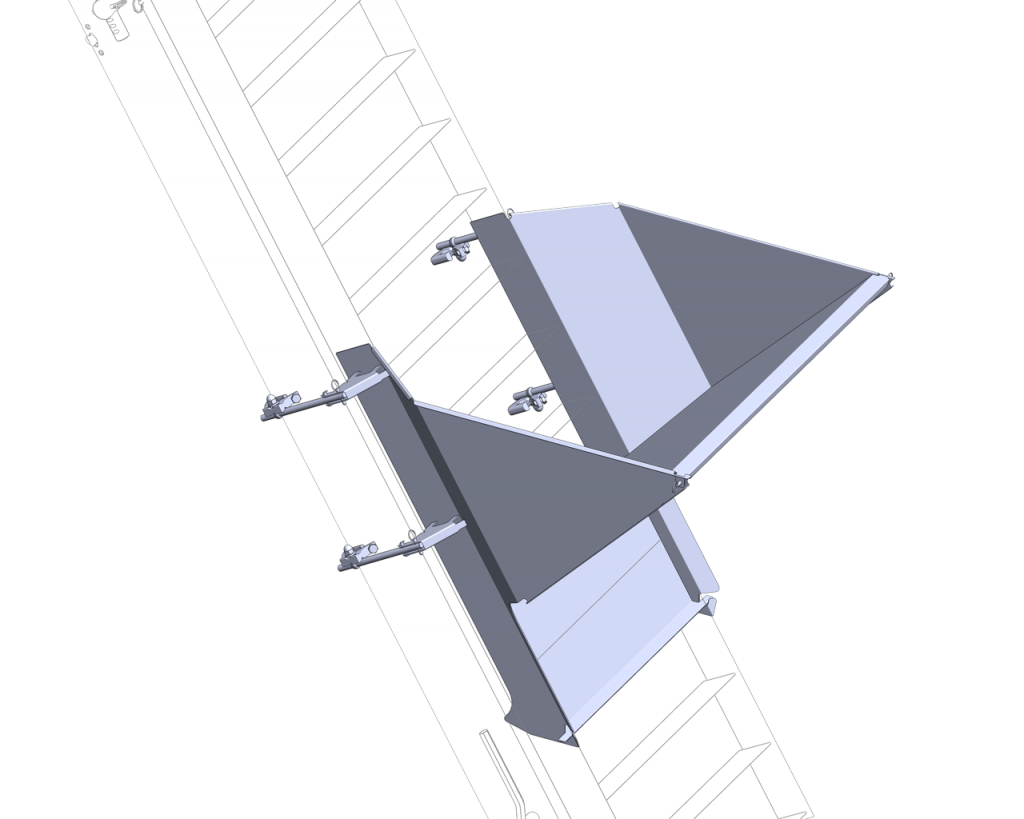

- Pulley located in conveyor frame with welded supports

- Pulley supports have quick locating and removal slot

- All frame components are a #4 finish

- Completely sealed components ideal for sanitary applications

- 50,000 hours of operation between oil changes

- 96% mechanically efficient

- Saves up to 30% power consumption over conventional motors

- Available on all 7400, 7600, & Ultimate Series

- 230 or 460 Volt 3 Phase

- VFD variable speed capable

- Speeds to 270 feet per minute

Features/Benefits:

- 304 stainless steel for durability in tough applications

- Sealed drum motor is ideal for heavy duty washdown applications

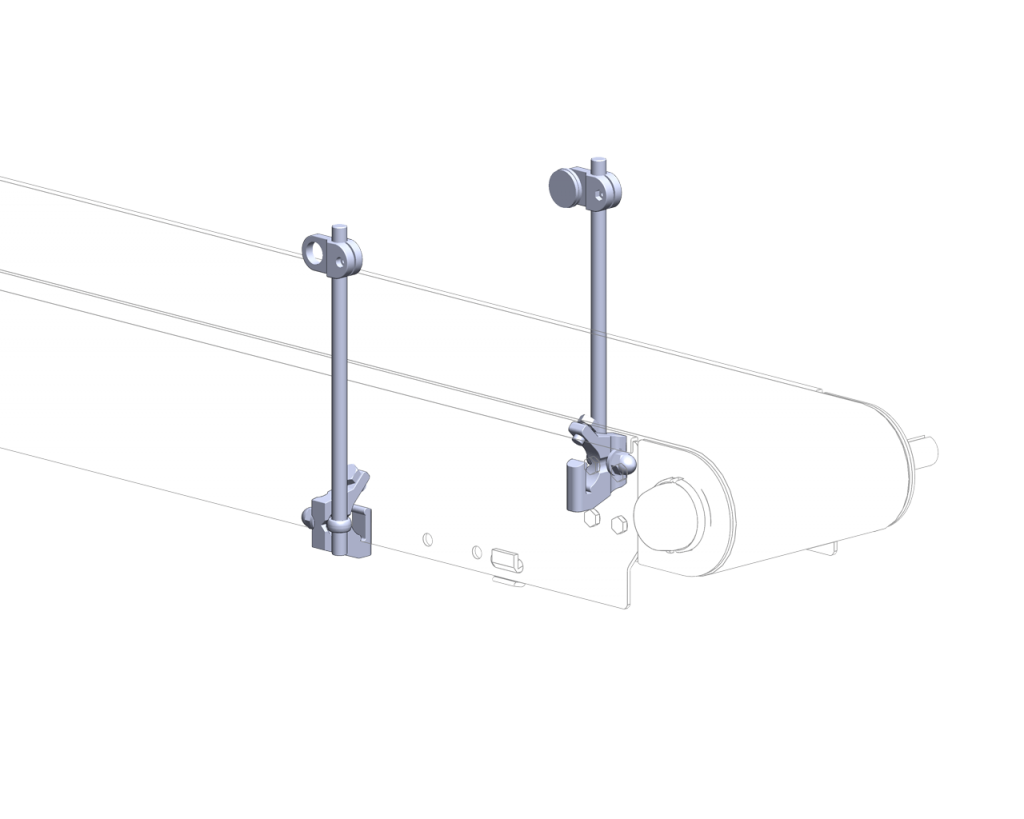

- Pulley locating supports allow for fast removal and relocating for sanitation

- No fasteners are used to locate sprockets on motorized pulley

- Innovative sprocket locating key way allows for fast and effective sanitation

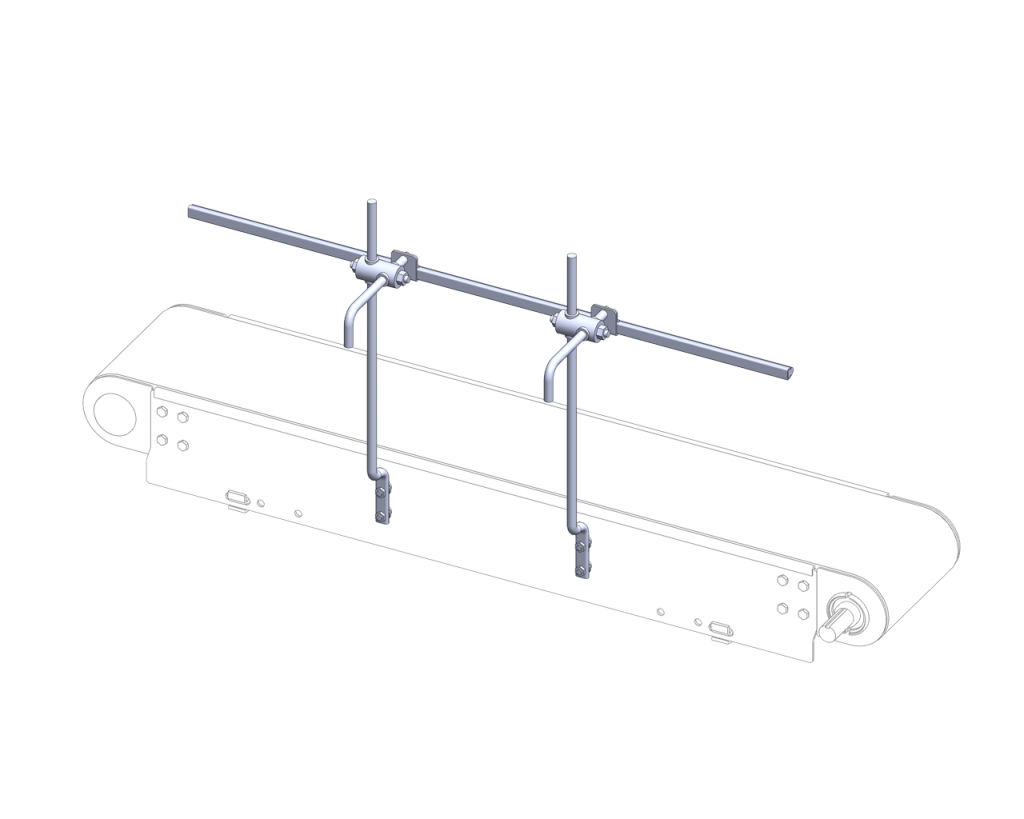

Progressive Key Sprocket Retention System*

- Locates low profile sprockets in place without the use of set-screws or fasteners

- Eliminates the possibility of fasteners loosening up and falling into the food zone

- The primary key is easily removed by shifting the main retaining ring then each progressive sprocket and key can be removed for fast effective sanitation

- When re-installed the sprockets are automatically located for proper mating with the conveyor chain

- Retention System works for both plastic chain and positive driven urethane belting

- *Patent Pending

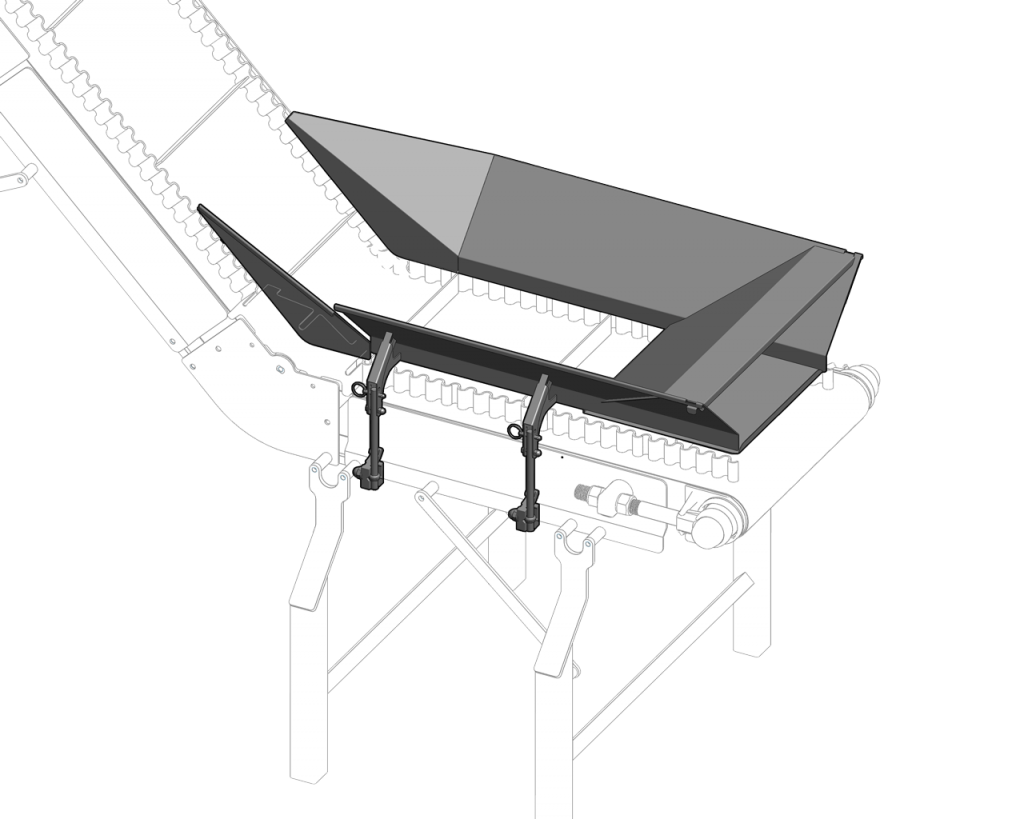

Accessories

Profiles

Belting

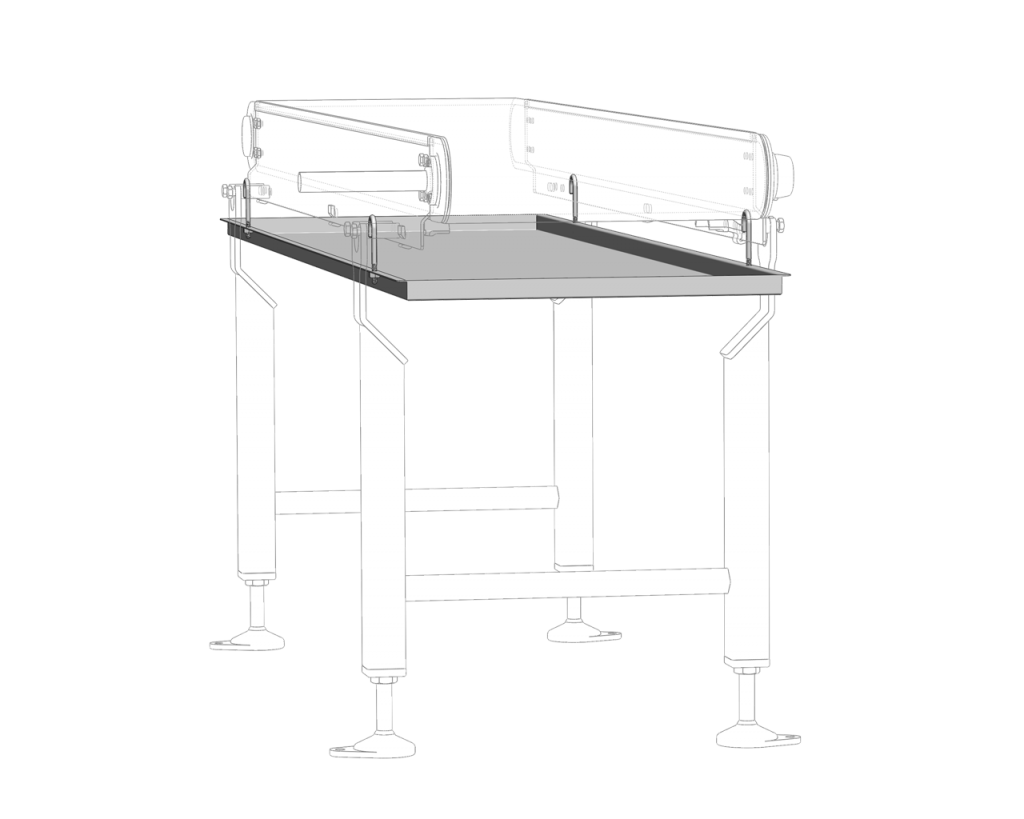

Support Stands

Gearmotors

Drive Mount Packages

Manuals & Literature

| AquaPruf Conveyors Brochure | 4 | 1.83 MB |

| Sanitary Conveyors Line Card | 6 | 5.97 MB |

| Dorner Sanitary Full Spec Rev. D | 224 | 25.7 MB |

| AquaPruf Accessories Brochure | 3 | 402 KB |