Butt splices aren’t the easiest things in the world to handle. The small, circular component designed to join two ends, or butts, of two objects together without overlapping, have been known to slip through fingers when inserting a wire connector while trying to crimp it.

The process of manufacturing butt splices can be challenging as well. That’s why Sumitomo turned to Smart Engineering Systems, Becker Engineering, Clayton Controls and Dorner Mfg., to streamline and modernize the manufacturing process and achieve greater accuracy in the positioning of splices during production from +/-.02” to +/-.002”.

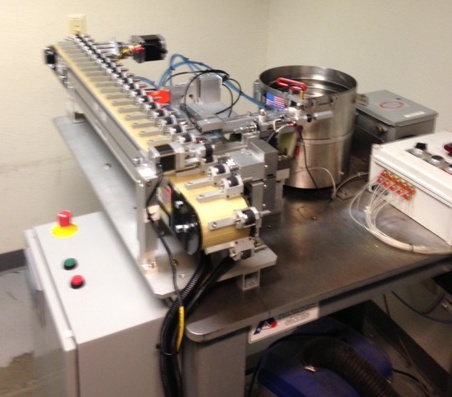

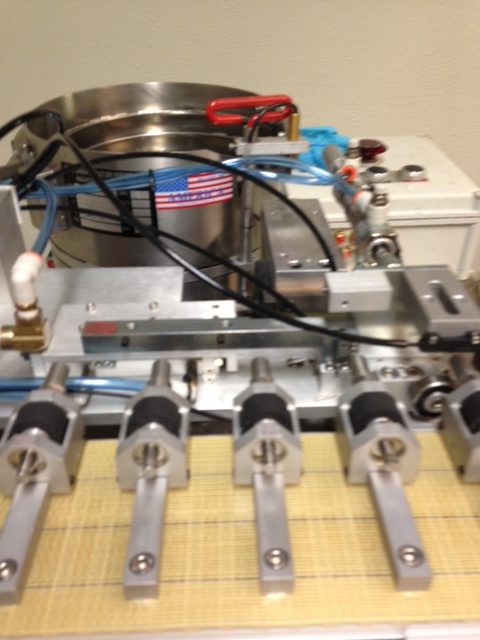

Sumitomo, a global company that’s involved in metal products, transportation, and construction, environment and infrastructure, chemical and electronics industries, was looking to update its equipment and help speed up the butt splice coloring process. Rob Greiner, P.E., at Carlsbad, California- based Smart Engineering Systems, said Sumitomo’s system for applying color to butt splices involves collecting parts into a vibratory bowl and then moving them down a linear feeder where a cylinder pushes them onto a rotating spindle. After the color is applied, the spindle is pulled away and the parts fall into a bin.

“Their old machine was kind of a make-shift deal. They fed parts basically into a felt pen, and that would apply the stripes to the butt splices,” Greiner said. “It was a pretty crude system and not very efficient. So they asked us to make a machine to solve that problem.”

Typical conveyors have their belts run continuously to transport parts, but this application had several specific requirements, which included: the ability to index the belt in incremental steps, pallet mounting hardware needed to be fixed at predetermined spacing on the belt, and they wanted to use an off-the-shelf solution so that they didn’t have to build it from scratch. Gerry Sakoda of Clayton Controls, a Costa Mesa, California-based automation solution provider, was brought in to help specify and select the correct Dorner conveyor that would meet all these needs.

Sakoda worked with Mark Becker, P.E., of Carlsbad, California-based Becker Engineering to provide the complete solution of mechanical engineering and electronic controls for the machine, and to ensure that the conveyor met all of the mechanical requirements. Becker also supported Smart Engineering on the motor sizing and electrical interface to the conveyor controls.

“Gerry was a real help in making sure that the conveyor system we chose would meet the customer’s needs,” Becker said.

The machine that Smart Engineering Systems and Becker Engineering designed sought to greatly reduce the drying time of parts and also increase production rates. Butt splices are fully dry before they are removed from the tooling mandrel. This is because the Dorner 3200 Series Precision Move Conveyor has many indexing stations available, something that is not achievable on a much more expensive cam type indexer. The machine’s design also allows for brighter and more consistent colors on the butt slices; two stripes can be applied simultaneously; operator intervention is not required during the process, and production costs are lower because no felt tip markers are required.

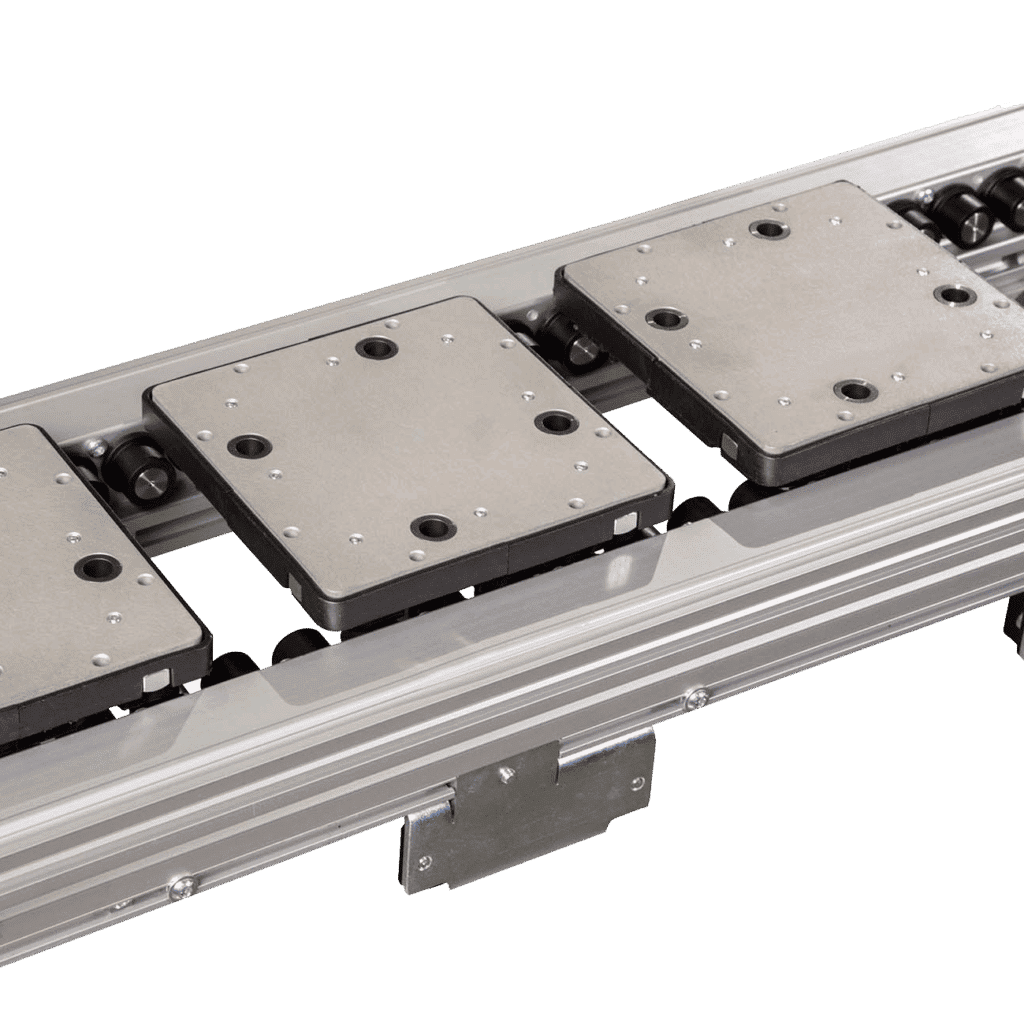

A key component in the new machine helping achieve an increase in production is Dorner’s 3200 Series Precision Move belt conveyor. Launched in 2012, the Precision Move conveyor platform uses a timing belt and drive technology for accurate movement of product at specific times, distances and intervals.

The need for precise conveyor movement made Precision Move a good fit for Smart Engineering Systems, as the application involves constant and precise starting and stopping of the conveyor.

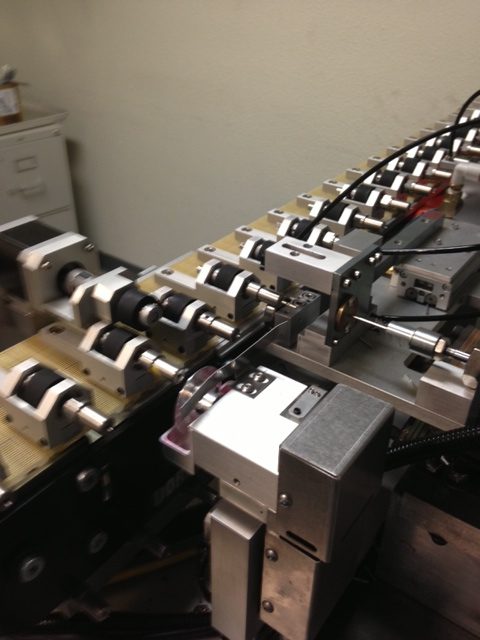

“One of the reasons we used Dorner’s Precision Move is that we can place the butt splice on a fixture mount attached to the conveyor, move it over to the print section, and do an ink transfer while the part is still connected to the fixture mount,” Greiner said. “The part then travels around the distance of the conveyor for one minute, giving time for the part and the color to cure. Next, the grippers grab the part and drop it into a container.”

Precision Move was designed for applications that involve machine integration, robotic pick-n-place, and precision indexing. It has an accuracy of +/- .02”, can carry up to 200 pounds and has belt speeds up to 370 feet per minute. The conveyor operates at a speed of about one inch per second for Sumitomo.

Sakoda and Becker together devised a method for increasing the positioning accuracy of the fixture mount from +/-.02” to +/-.002”. This increase represents an accuracy 10 times greater than was previously thought possible.

“We used a fiber optic area sensor to detect the leading edge of the fixture mount as it approached the splice loading station,” Becker said. “In conjunction with a stepper motor drive we were able to attain the increased accuracy at this one critical loading station. The mandrel on the smallest fixture mount is only .043” in diameter, so +/- .02” is nearly 50 percent of the mandrel diameter. We needed better positioning and actually got better results than we expected.

“The Precision Move conveyor worked out great for us and is much less expensive than an equivalent machine tool type indexing conveyor.”

Precise accuracy isn’t the only enhanced capability of the new system. Greiner said the combination of the new machine and conveyor has more than doubled production of colored butt splices to about 60 per minute. It also features quick-change tooling; allowing Sumitomo to change colors more efficiently.

“Our machine is much more robust than what they had been using, and has more logic to help them identify things that might go wrong,” Greiner said. “Another added plus is that we reduced the drying time before the part ever gets touched, and that reduces smears.”

Greiner said he’s used Dorner in the past for other projects, and the reason he keeps using them is because he can order them built to his exact specifications.

“Dorner conveyors are streamlined, have a sturdy design and fit where other conveyors don’t,” he said. “They come assembled and ready to run, whereas it always costs us something if we have to do some custom fabrication. We can buy the conveyor, simply mount it and we’re done.”