Dorner Asia recently worked with an automotive machine maker in Malaysia to integrate a conveyor with a robot for a pick and place system.

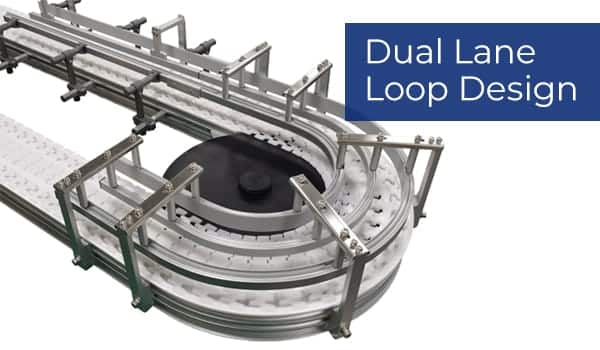

The application required two lanes of pucks that would be running in a loop. Dorner was able to create two lanes on one conveyor using custom guiding including a center top guide.

The top guide in the middle ensures that the center to center pitch of the pucks stays consistent around the corners.

FlexMove Conveyor

The base conveyor is a FlexMove FL 150 mm Conveyor. The conveyor features a top running loop which creates a continuous circuit of conveyance. Top running loops are ideal for puck handling applications as well as pallet systems and small manufacturing cells.

In the final system, a stopper module will hold the pucks in place at a certain point on the loop for scanning. A robot will then unload them to another machine for further processing.

Application During Test Stage

The video below shows the application before the stopper module was added.

Learn more about Dorner’s FlexMove Conveyors.