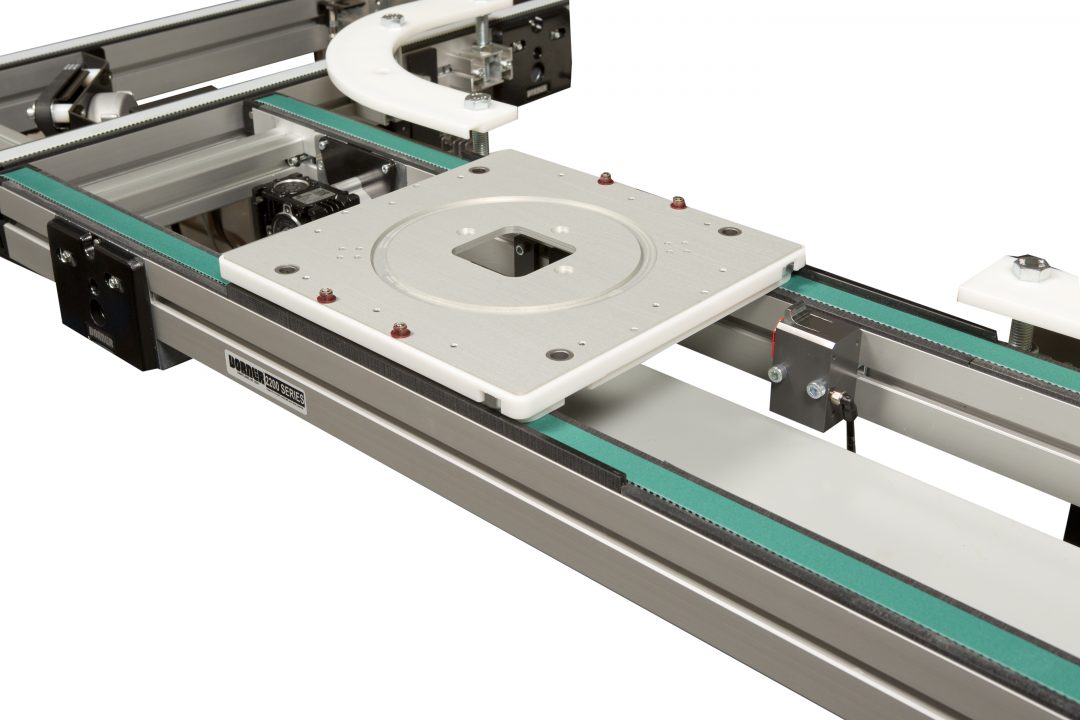

Dorner Latin America continues to grow their capacity by adding the 2200 Series Precision Move Pallet System Conveyor as its fourth major platform to be assembled at their facility in Guadalajara, Mexico. The 2200 Series Precision Move Pallet System Conveyor is designed to increase efficiency and reduce downtime in assembly automation processes for their latin america customers.

Dorner is an industry leader in the design, application, manufacturing and integration of precision industrial and sanitary conveyor systems.

The 2200 Series Precision Move Pallet System comes with many benefits for the assembly automation industry, including a heavy-load corner design to carry and accumulate loads up to 70 pounds around 90° or 180° corners and effectively provide loop capacity for larger, heavier pallets. Pallet widths have also been expanded to 640 x 640 mm to handle these heavy loads.

Dorner’s pin tracking system offers a cost-effective option that eliminates the need for other transfer devices while maintaining pallet orientation through the loop, an advantage not typically seen in most systems.

The low-profile lift and locate is ideal for operator stations, as the feature lifts the pallet off the conveyor and locates it within +/- 0.015”. The compact and safe device protrudes only 1” beyond the main conveyor saving valuable space for operators or other equipment.

Additionally, the 2200 Series Precision Move Pallet System offers an elevator option that uses dual-sided timing belt conveyor technology to effectively raise and lower pallets for over/under pallet applications. Dual sided support provides an improved method of transport for wider pallet applications.

Users can design a simple or complex 2200 Series Precision Move Pallet System with DTools, Dorner’s online conveyor configurator. Complete with 2D and 3D CAD drawings and other functions, DTools gives customers the design tools needed to fully configure their belt conveyor systems in minutes.

Dorner Latin America began building conveyors for their Latin American customers from its Guadalajara, Mexico facility in early 2018, starting with the 2200 Series low profile conveyor. The company then added the FlexMove flexible chain conveyor and the 2200 Series Modular Belt conveyor. All Dorner conveyors and equipment will be supported through the Guadalajara customer service and engineering teams.