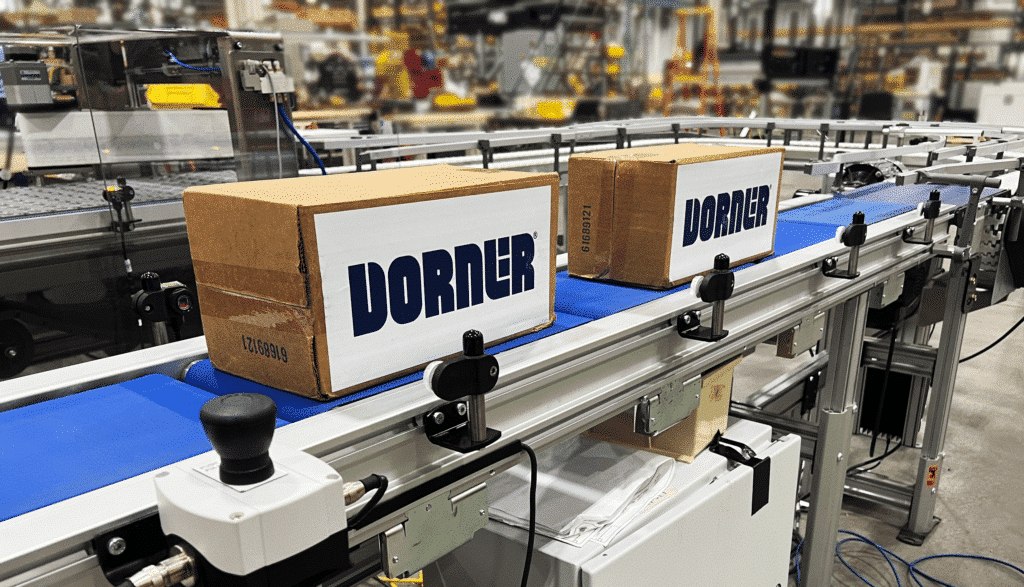

As Pack Expo quickly approaches, Dorner’s team is already gearing up for a full week of sharing intelligent motion conveyance solutions with manufacturing and packaging professionals. We’re counting down the weeks to the show with previews of the conveyor technology that we will be featuring in our booth.

This week, it’s all about packaging with our industrial packaging loop. This system features some of Dorner’s most customizable conveyors, such as the 2200, 3200 ARB, FlexMove, and ERT Belted systems. Each conveyor also features several added accessories to demonstrate the versatility of each series.

3200 ARB

Our 3200 ARB conveyor combines the durability and power of Dorner’s 3200 conveyor with Intralox’s activated roller belt (ARB) technology. Rollers built into the belt are designed to roll in a different direction than the main belt when pressure is applied. As a product is pushed against a barrier or guard it will seamlessly change direction, allowing for easy line transfers or repositioning without manual intervention.

Specs:

- 2″ pitch ARB Chain

- Widths: 8″ (203 mm) to 60″ (1524 mm) in 2″ (51 mm) increments

- Lengths: Minimum 3 ft (914 mm)

- Speeds: Up to 150 ft/min (46 m/min)

- No adjustment needed for different sized products

2200 Powered Side Guide Divert

The 2200 Powered Side Guide Divert features a low-profile aluminum frame designed to easily redirect product as it moves down the production line. By utilizing a powered diverter over a static diverting guard, the diverter can be adjusted to a wide range of angles while still offering the same accuracy and speed in directing product.

Additionally, by combining this conveyor with an ARB conveyor, many different sized products can be transferred along the same line and repositioned without the need for adjustments or changeovers.

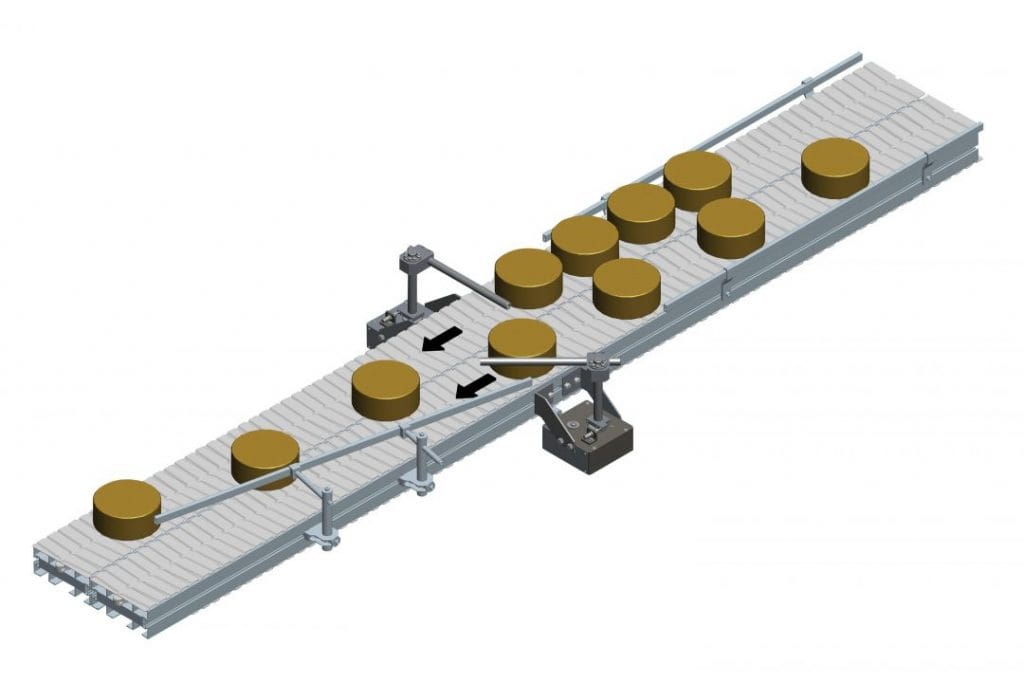

FlexMove Side Acting Merge

Another option for transferring products between lines or merging multiple lanes into one can be seen with the FlexMove Side Acting Merge. This part of the loop demonstrates Dorner’s FlexMove flexible plastic chain conveyors with a side-acting module designed for two-to-one lane merging without the need for control logic or added machinery.

The FlexMove Side Acting Merge is a completely mechanical module that creates a first-in, first-out product merge to align product quickly and safely for the next step in production. We’ve engineered this module to be easily adjusted the force required to activate the diverting arm, and it can be modified for varying heights and lengths to accommodate any sized product.

Belted ERT

The Belted ERT combines all the benefits of Dorner’s patented Edge Roller Technology with a belted precision conveyor. The ERT’s gear drive allows for custom reconfiguration in the field to adjust the number of pacing belts and lengths required by the applications. This system is ideal for pacing packaged goods for accurate labeling, palletizing, or sorting. With a simple pre-configured 24VDC motor, the Belted ERT conveyor is energy efficient and can be seamlessly integrated into an existing production line.

Advanced Packaging Conveyor Solutions from Dorner

From assembly and inspection to packaging and shipping, Dorner offers state-of-the-art conveyance technology to add efficiency and speed to any production line. Visit our team at booth C-1455 to learn more about our conveyor systems and find the right fit for your application.

Use code: 33R73 for a discount on your registration, and add Dorner to Your Pack Expo Itinerary!