When you need to move product from one conveyor to another that’s often where challenges arise. You could just put the two conveyors as close together as possible and if your product is large enough it will go from one conveyor to the next. However, there’s still the chance of it falling into the gap between the two and damaging product as well as the conveyors. Then there’s the problem if your product is too small to bridge the gap how to get it from one to the other.

There are many options for transferring products between conveyors but they have drawbacks that don’t make them suitable for a lot of applications. There are static transfer plates, roller transfer plates, and nose bar tails. Static transfer plates close the gap between conveyors but don’t maintain either motion or speed and can cause product backups. Roller transfers maintain motion but not speed causing product accumulation at the point of transfer or further down the line. Lastly, conveyors with nose bar tails are a great option but can limit your options when choosing a conveyor.

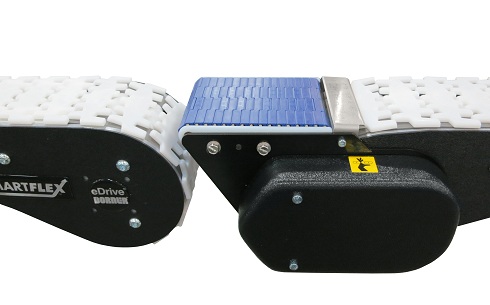

That’s where the Powered Transfer comes in. When moving smaller products between conveyors it’s an ideal solution because of its small sizes and series drive connectivity which make it easy to integrate with your conveyors. Also because the Powered Transfer is series driven it will maintain tracking and speed of whichever conveyor it is connected to. It is also small enough that it is easily integrated in most spaces without eating up valuable space

The Powered Transfer makes sure that no products get damaged with a nose bar of only ½”. This is great for applications where large conveyors are needed causing large gaps between conveyors. With the Powered Transfer, gaps between conveyors can be nearly eliminated allowing for near-seamless product transfers. This transfer provides reliable and gentle product transfers ensuring that your product reaches its final destination safely.