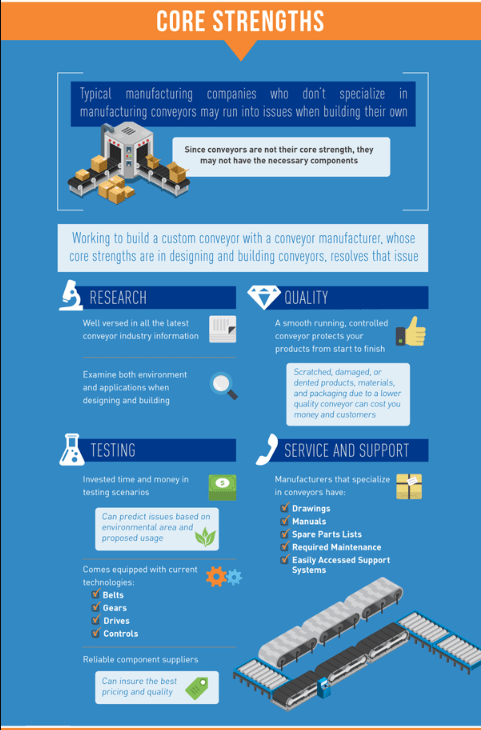

Core Strengths

We know you’re experts at what you do, and so are we, which is why our core strengths focus on building custom conveyors and manufacturing buyer ready conveyors for a wide range of industries. Our conveyors do the grunt work, giving you the opportunity to do what you do best — create quality products. This allows us to do the research, quality control, testing, and provide you with service and support that is unparalleled in the conveyor manufacturing industry. We can help you determine whether you should make or buy, it’s part of what we do.