The Latest in Conveyors: Edge Roller Technology

Access The Latest in Conveyors: Edge Roller Technology Webinar

With an array of models available, you’ll find a conveyor belt material handling solution for small components and large boxes, for straight or curved paths, and for on the ground or overhead. In addition to our standard conveyor offerings, Dorner offers custom material handling and industrial conveyor solutions designed for your unique space and business needs.

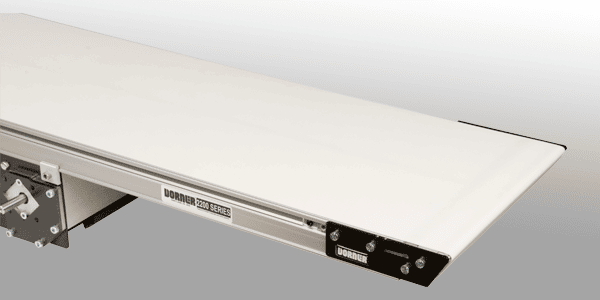

Low profile, high performance conveyors. Industry best v-guiding provides positive belt tracking while precise rack and pinion allows for fast and simple belt tensioning. Durable, yet flexible in design these conveyors are best for small to medium part handling, precision movement, positioning, accumulation, part routing, assembly, and transfers.

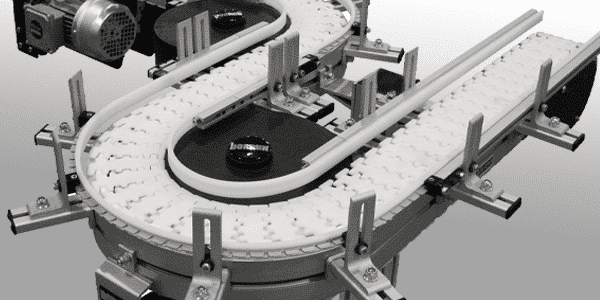

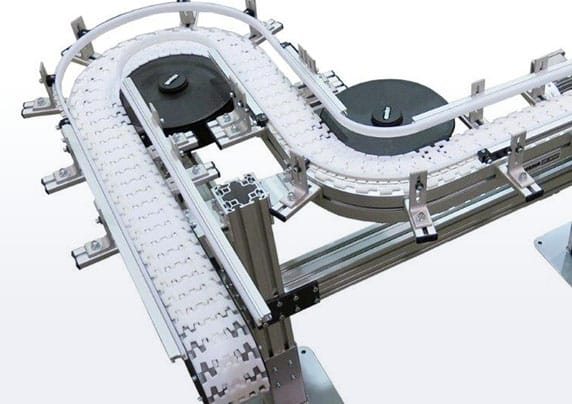

FlexMove conveyors are a customizable solution designed for tight spaces and also offer the flexibility to grow along with your needs. This series of material handling and industrial equipment can handle twists, multiple curves, inclines and declines on a single conveyor. FlexMove conveyors can also move products as small as 3 inches in diameter.

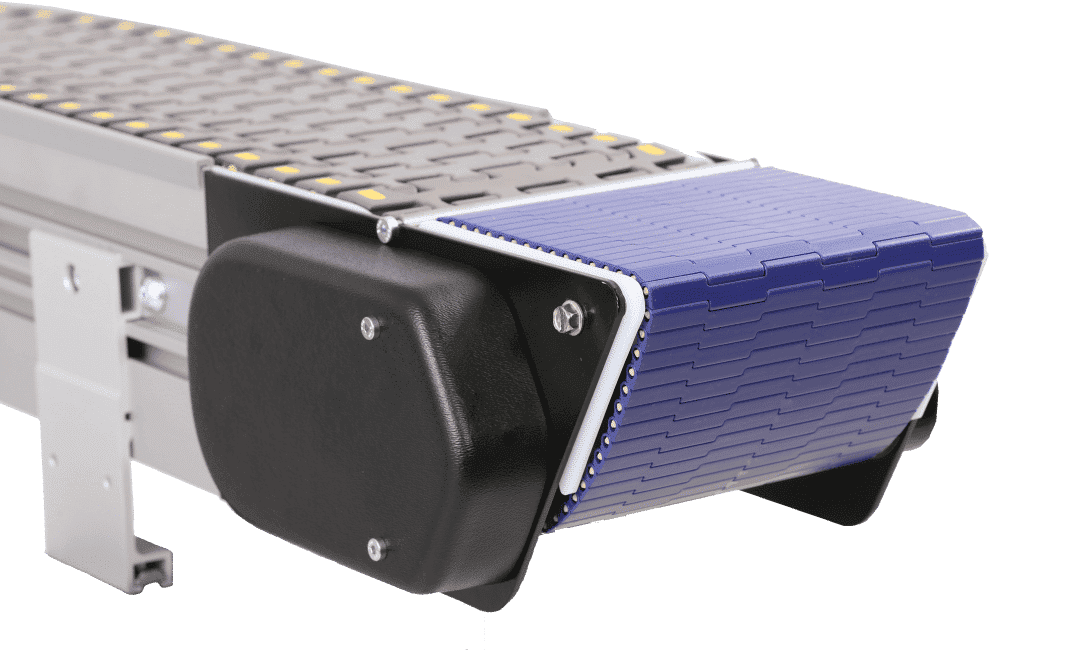

Reliable and adaptable edge roller platform for the conveyance of medical and cleanroom-based product assembly or assembly automation. These conveyors feature an open drive roller design with aluminum frames, with non-contact zoning and/or slip roller accumulation capability. Additionally, ERT 250 Conveyors are ISO Class 4 verified* for cleanroom applications.

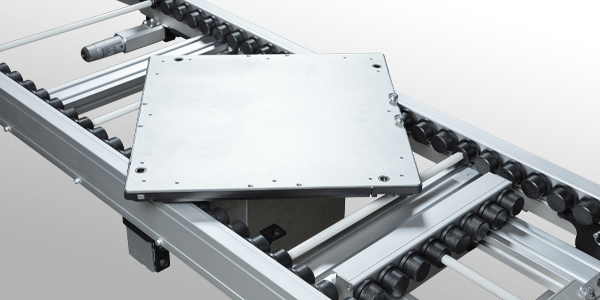

Simply put, material handling and industrial conveyors move products from one place to another such as throughout a distribution center or through various steps in the production process. These systems are seen in a wide variety of industries, from automotive to pharmaceutical.

Conveyor belts for material handling and industrial can be used for a variety of applications, from part handling and packaging to assembly automation and accumulation. Although typical loads include boxes, totes and packages, sanitary conveyors also handle food processing and packaging edible products, even fresh fruit and raw meat.

*To verify clean room requirements, an unloaded base conveyor was tested and did not generate particulate that would be beyond the specified standards. However, the verification does not provide assurance that any or all applications will meet this requirement. Application testing is recommended to ensure clean room standards are being met. Dorner takes no responsibility in the clean room performance of the final conveyor or application.

Access The Latest in Conveyors: Edge Roller Technology Webinar

Access Edge Roller Conveyor Technology eBook What’s in the eBook? When deciding between a belt conveyor and an edge roller

WISCO Industries Inc. is a producer of high-quality metal stampings, fabrications and food service equipment for major OEMs. When a

In today’s busy production facilities – things always change quickly. And, nobody can afford a time-consuming changeover. It’s critical for

In today’s fast-paced production facilities, machines move quickly, workers are busier than ever and space is at an absolute premium.

Providing precise product placement with the ease and cost-effectiveness of a belt conveyor. By:Michael Hosch, P.E.Director of Product DevelopmentDorner Mfg.

Conveyor Accuracy HOW DOES CONVEYOR ACCURACY AFFECT YOUR APPLICATION? A key component to the success of your application is the

Accessing Your Business’s Full Potential Growing companies that are looking to increase their production numbers to meet growing demand are

LEARN HOW OUR PRODUCTS CAN HELP YOUR BUSINESS

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy

We may place these for analysis of our visitor data, to improve our website, show personalized content and to give you a great website experience. For more information about the cookies we use open the settings. Privacy Policy.