- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Thank you for downloading our eBook!

5 Methods for Improving Pharmaceutical Processing Through Conveyance

Interested in Learning More About Dorner's

Pharmaceutical Conveyor Solutions?

Applications for Conveyors in Pharmaceutical Processing

Precision conveyors can add efficiency, speed, and improved accuracy to pharmaceutical manufacturing and prescription fulfillment processes. With the wide range of conveyor solutions Dorner has to offer, we can design, build, and install conveyors for almost any application, including:

- Compressing pills

- High-speed bottle filling

- Blister packaging

- Pill capping

- Offline inspections

- Sorting and grouping

- Product accumulation

- Rejecting and transferring

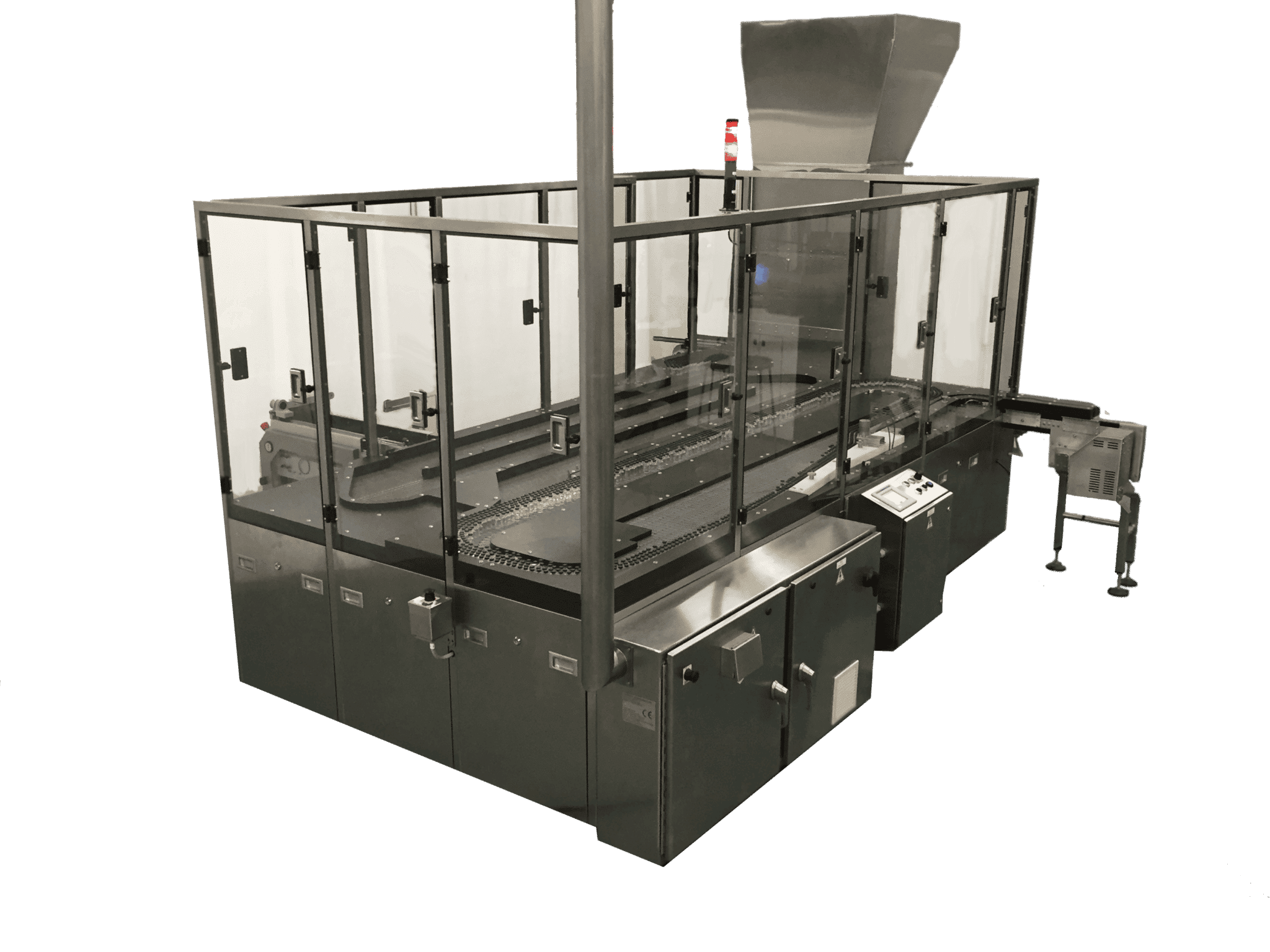

Custom Tote Conveyor System for Prescription Fulfillment

Our Engineered to Order team has recently designed and built mail service prescription processing and fulfillment conveyors for a large national retailer. These conveyor systems are comprised of two connected lines. One transports prescription bottles to be labeled, scanned, and filled, and the other carries totes for orders to be compiled and inspected by operators before moving on to packaging.

This client needed a fast, accurate solution for handling and processing prescription orders, while also offering safe and ergonomic work stations for employees to fulfill and inspect orders before packaging. Watch the video below to see the system our team built in action.

Ready for a new conveyor system?

PROJECT EVALUATION

Discovery

Proposal

Quote

EXPERIENCED ENGINEERING

Kick-off

Dedicated Team

Drawings

Delivery Schedule

SYSTEM MANUFACTURING & TESTING

Manufacturing

Testing

Shipping

FIELD START-UP

On-Site Start-Up

Troubleshooting

Customer Satisfaction

TRAINING & AFTERMARKET SUPPORT

On-Site Training

24/7/365 Service

Pharmaceutical Conveyors

FlexMove - Flexible Chain Conveyors

As one of the most customizable conveyors on the market, FlexMove systems offer the high-performance versatility needed to stay competitive in the pharmaceutical industry. These conveyors can be configured with multiple curves and inclines on the same line, saving valuable floor space while maintaining efficient product handling. FlexMove conveyors can also be customized with numerous modules and accessories for product flow control, inspection, belt cleaning, and more!

Specifications

- Widths from 45-260 mm

- Lengths from 0.6-30 m (2-98 ft)

- Loads up to 272 kg (600 lbs)

- Speeds up to 76 mpm (250 fpm)

Ideal Applications

- Prescription fulfillment

- Tote conveyance

- Accumulation & precise product flow

- Packaging & logistics

1100 Series Miniature Conveyors

Dorner’s 1100 Series Miniature conveyors are the industry’s smallest conveyors. With a frame height of only 3/4″, this system is perfect for fitting inside machinery and handling small, delicate products such as pill packs and vials. The 1100 series features a reversible drive and universal t-slots for added flexibility in application and accessory mounting.

Specifications

- Widths from 44-254 mm (1.75-10″)

- Lengths from 270-1829 mm (10.63-72″)

- Loads up to 6.8 kg (15 lbs)

- Speeds up to 21 mpm (80 fpm)

Ideal Applications

- Small pharmaceutical processing

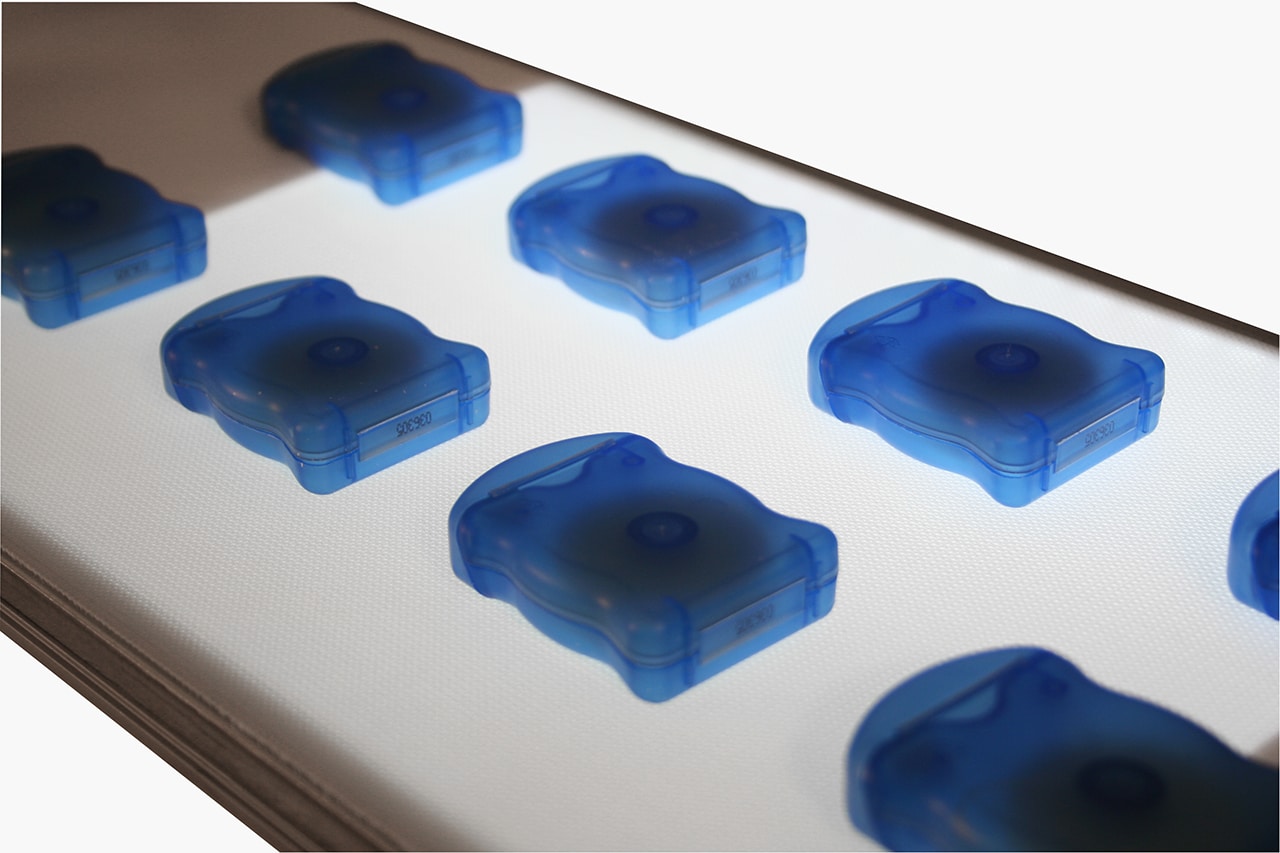

- Blister pack filling & transfers

- Backlit inspection

- Packaging

2200 Series Low Profile Conveyors

Our 2200 Series Low Profile conveyors are the preferred solution for a wide range of industries including prescription fulfillment and pharmaceutical manufacturing. The low profile frame allows this conveyor to easily fit into tight spaces and integrate with other machinery. Similar to the 1100, the 2200 series also features t-slots for accessory mounting along the entire length of the frame. This combined with the largest selection of belting options makes the 2200 a highly customizable conveyor solution.

Specifications

- Widths from 44-610 mm (1.75-24″)

- Lengths from 457-7315 mm (1.5-24′)

- Loads up to 54 kg (120 lbs)

- Speeds up to 122 mpm (400 fpm)

Ideal Applications

- Small parts transfer

- Small product accumulation

- Machine integration

- Pharmaceutical packaging

AquaGard LP Sanitary Stainless Steel Conveyors

The AquaGard LP is a low-profile, sanitary stainless steel conveyor rated for low pressure wash downs with soap and water cleaners. This system features tip up tails for quick belt cleaning and change overs, as well as a compact, enclosed tensioning system for easy maintenance. The streamlined design of the AquaGard LP allows this conveyor to fit where others do not, making it perfect for sanitary integration applications in pharmaceutical manufacturing facilities.

Specifications

- Widths from 70-457 mm (2.7-18″)

- Lengths from 500-5485 mm (19.7″-18′)

- Loads up to 22.7 kg (50 lbs)

- Speeds up to 75 mpm (246 fpm)

Ideal Applications

- Sanitary manufacturing environments

- Pharmaceutical packaging

- IV Bag packaging & transfers

- Automated process integration

ERT150 Pallet Conveyors

The ERT150 features Dorner’s Edge Roller Technology. The open frame design eliminates jamming and pinch points, and reduces the friction and particulate buildup seen frequently on traditional belt conveyors. Pallets are transported along rollers for smooth movement and no back pressure accumulation, making this system ideal for sensitive products such as vials and liquid pharmaceuticals.

Specifications

- Widths from 70-457 mm (2.7-18″)

- Lengths from 500-5485 mm (19.7″-18′)

- Loads up to 22.7 kg (50 lbs)

- Speeds up to 75 mpm (246 fpm)

Ideal Applications

- Automated pharmaceutical processing

- Vial filling & accumulation

- Medical inspection & testing

- Pallet & tray handling

Automatic Vial Dryer from Garvey

In temperature-sensitive pharmaceutical production, any time out of the cold chain can negatively affect the potency of a product. One of the biggest contributors to the time pharmaceuticals are outside of the cold chain is in packaging and inspection, where products can be at room temperature for 24-48 hours.

With Garvey’s Automatic Vial Dryer, this time can be cut down to as little as 5 minutes! The modular design keeps the vial drying system flexible and easily configurable to fit into tight production layouts. It also includes various in-feed and out-feed options and can be customized to meet the needs of your production line.

Ready to Get Started? Contact Us for Your Custom Pharmaceutical Conveyor

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy